High-bonding-strength plastic-lined compound pipeline and technical method

A technology that combines strength and process methods, applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problems of corrosion leakage, leaking pipes, glue opening of steel-plastic joints, etc., so as to improve the bonding adhesion and improve the Fatigue resistance, improvement in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

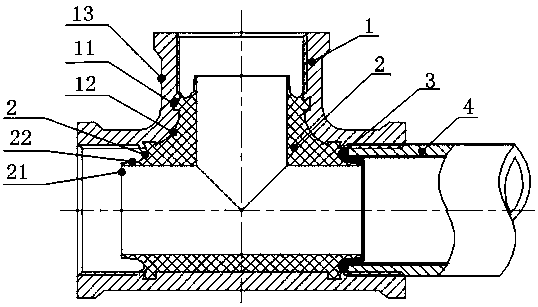

[0031] Such as Figures 1 to 2 Shown is an embodiment of a high bonding strength plastic-lined composite pipe fitting and its process method of the present invention. The composite pipe fitting is a three-way pipe fitting. The composite pipe fitting includes a pipe fitting body 1, a lining plastic body 2, and a pipe material 4. The lining plastic body 2 is installed In the pipe fitting body 1, the pipe material 4 is clamped between the pipe fitting body 1 and the inner plastic body 2, and the inner surface of the pipe fitting body 1 in contact with the inner plastic body 2 is provided with a hook groove 11, which is different from the coating at the position of the hook groove 11. Covered with a hot melt adhesive layer 12. The surface 13 of the pipe fitting body is treated by galvanizing or coating with high adhesion resin paint

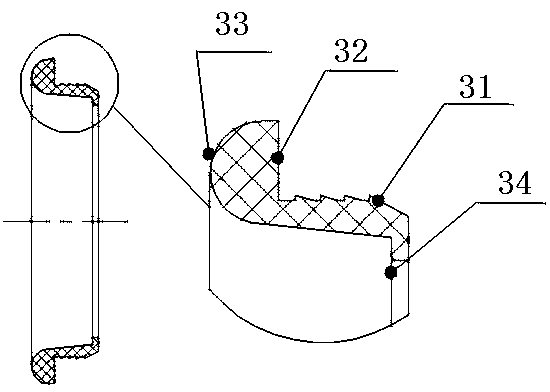

[0032] Wherein, a sealing ring 3 is provided at the position where the pipe material 4 is clamped with the inner plastic body 2 , and the sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com