A device and method for automatically measuring the external friction angle of solids

A technology of external friction and monitoring devices, which is applied to the device for automatically measuring the external friction angle of solids, and in the field of automatic measurement of external friction angles of solids, can solve the problems of cumbersome experimental procedures, unfavorable ore and rock bulk, and reduced experimental accuracy, so as to achieve analysis and Summarize the effects of convenience and accuracy, reduced impact, and high data reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

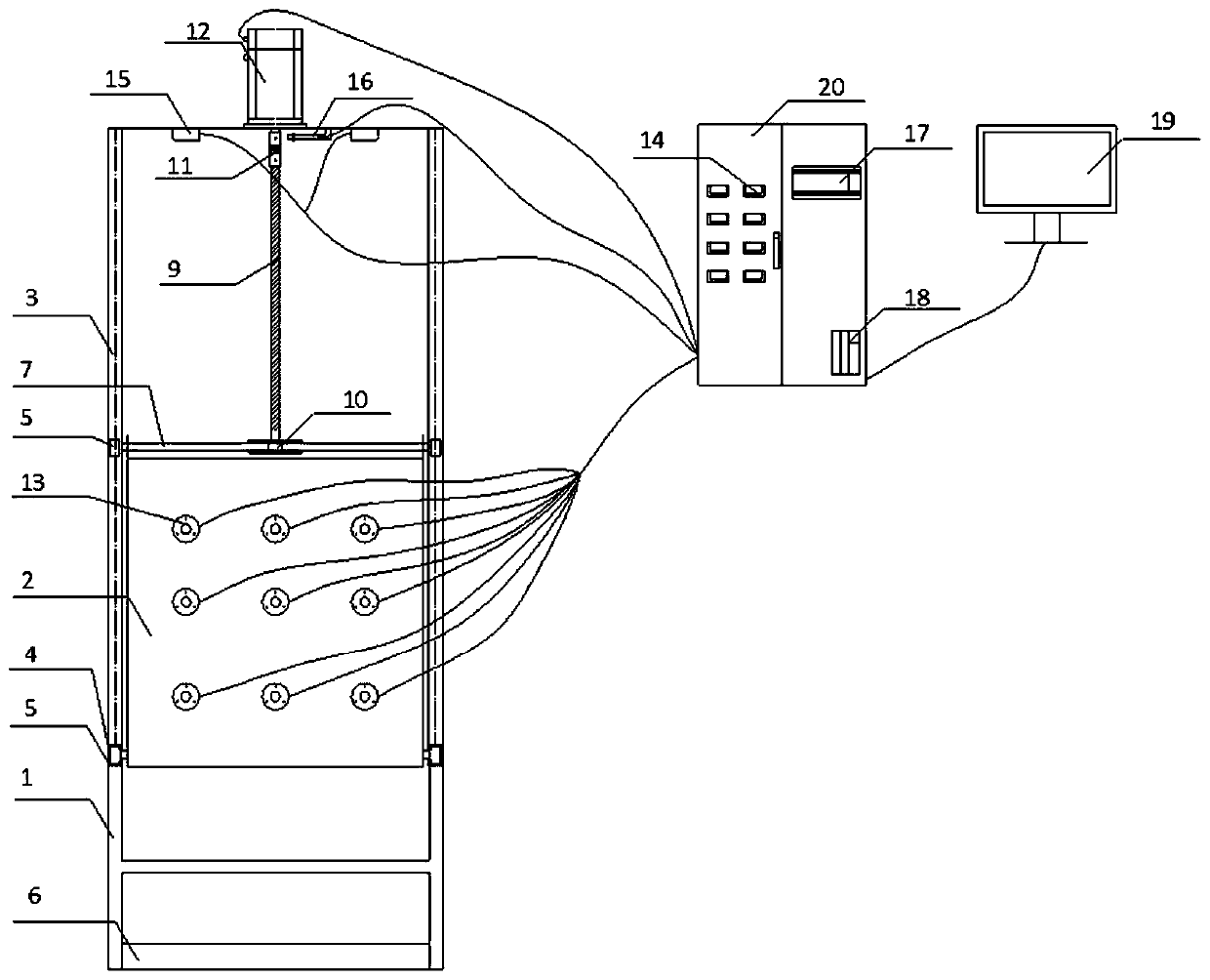

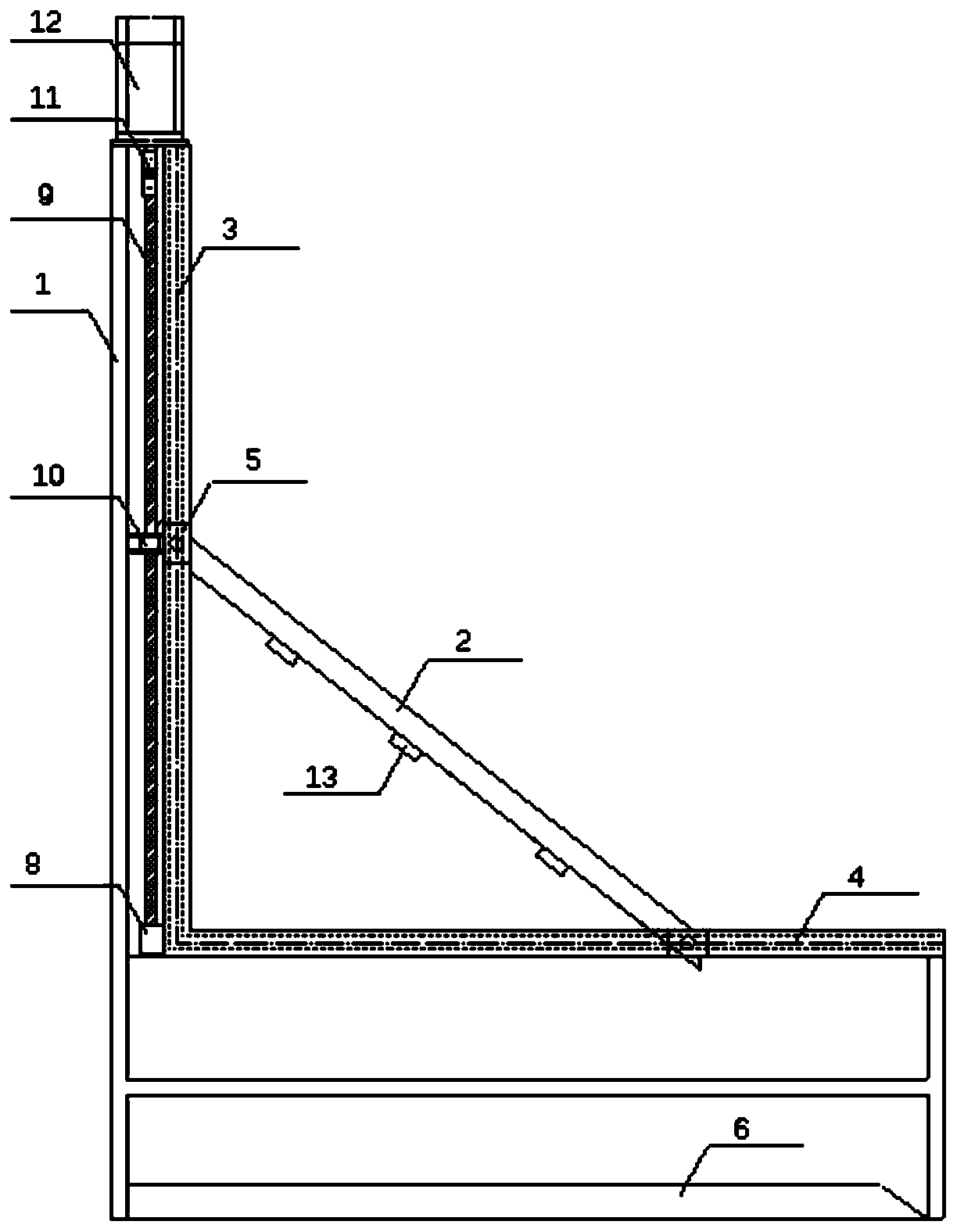

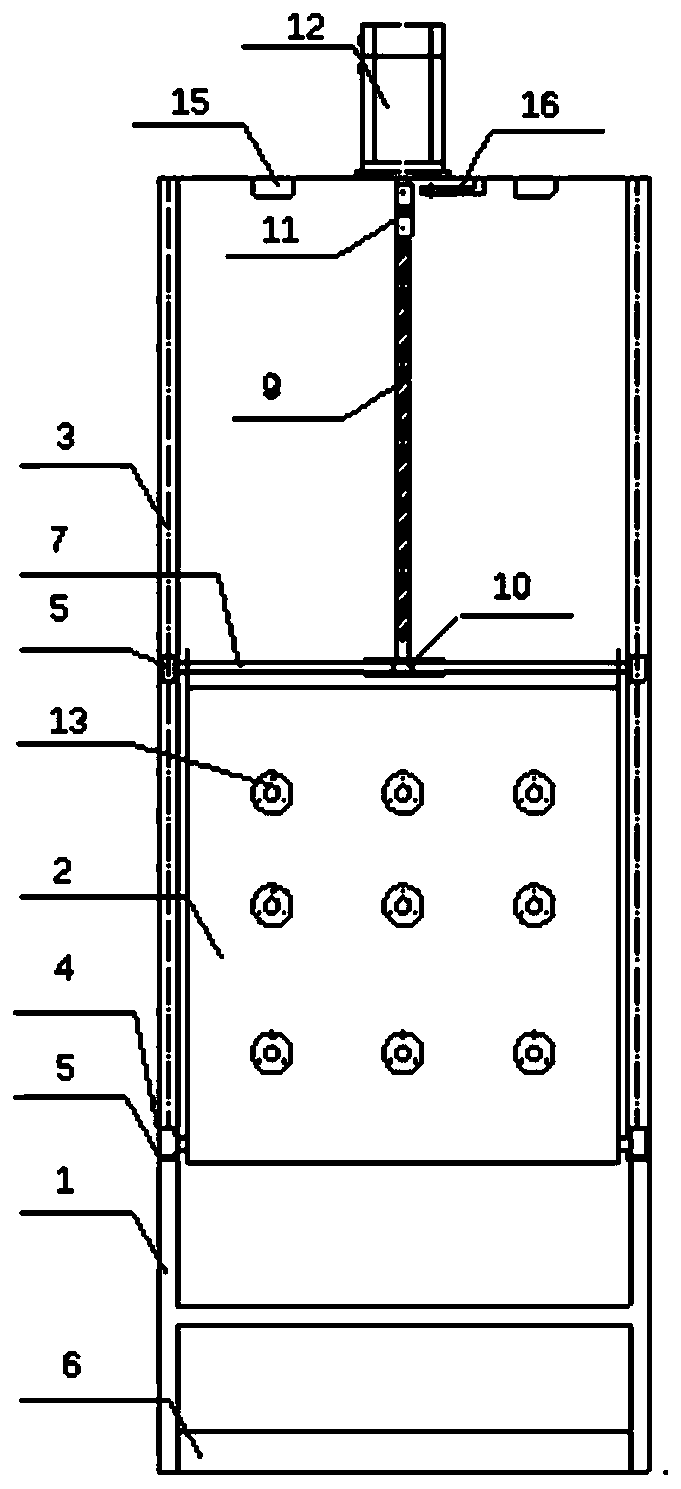

[0039] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0040] Such as figure 1 , figure 2 and image 3 As shown, including inclinometer, lifting device, monitoring device and control system. The incline meter and the lifting device cooperate with each other to realize the process of changing the ore bulk from a static state to a moving state. The monitoring device monitors whether the ore bulk changes from a static state to a moving state, and can also monitor the moving state of the lifting device. The control system By connecting inclinometers, lifting devices and monitoring devices.

[0041] The device rack 1 of the inclinometer has a vertically arranged vertical guide rail 3 and a horizontally arranged horizontal guide rail 4, and the two form a right-angle structure. The direction of the vertical guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com