Transformer and coil assembly

A coil assembly and transformer technology, applied in the field of transformer equipment, can solve the problems of low working reliability and safety of transformers, large short-circuit mechanical force, short-circuiting of wires, etc., to prevent short-circuit mechanical force, avoid lateral magnetic flux leakage, and ensure reliability. Effects of Sex and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

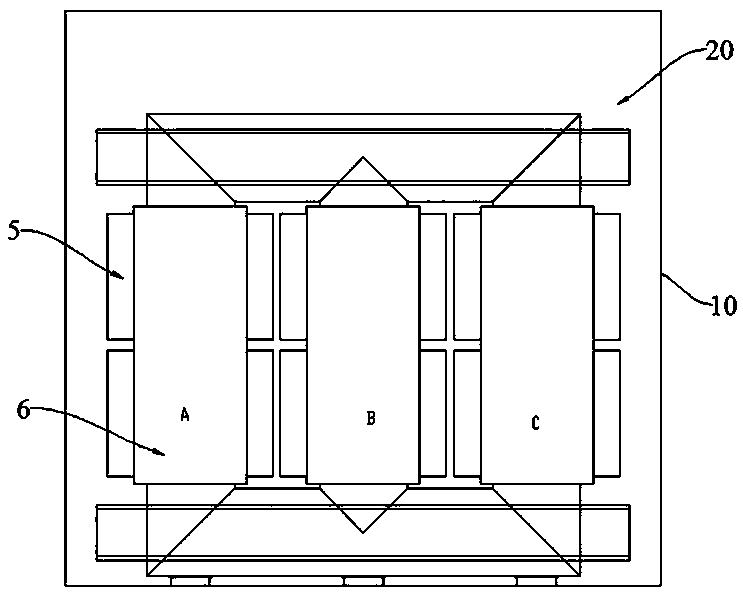

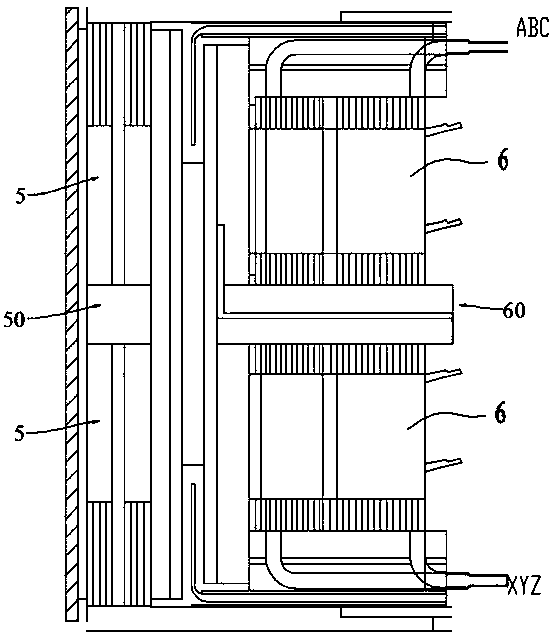

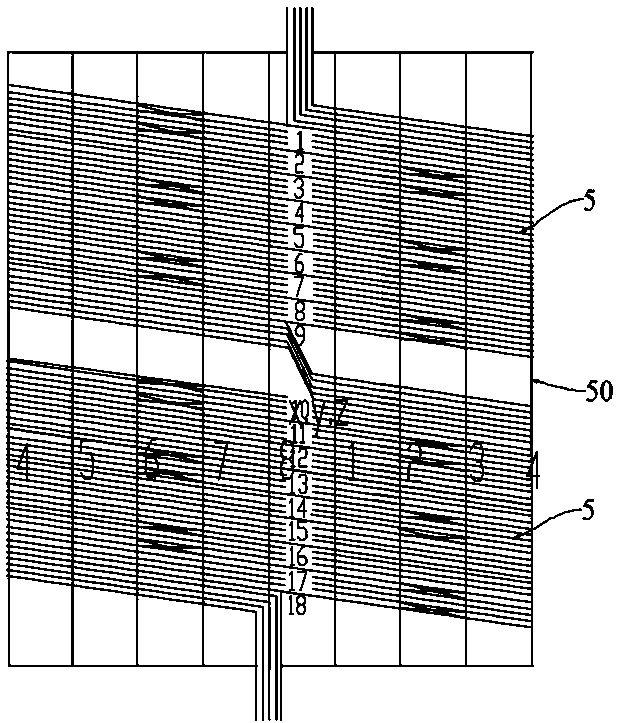

[0024] Specific embodiment 1 of transformer of the present invention, as Figure 1 to Figure 6 As shown, the transformer includes a housing 10 and a coil assembly 20 installed in the housing 10, and the housing is filled with insulating oil. The coil assembly 20 includes an iron core, a high voltage coil 6 and a low voltage coil 5 wound on the iron core. Among them, the low-voltage coils are double-helical in the longitudinal oil passage, and they are left-handed. The total number of turns of each phase coil is 18, such as Figure 6 As shown, the single-turn parallel winding form is 2*6, including the inner parallel winding wire 30 and the insulating sheath 31 outside the parallel winding wire 30 . Of course, the parallel winding method of the single-turn coil can also be adjusted according to actual design parameters.

[0025] The high-voltage coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com