A loss-reducing ventilation device at the end of a large-capacity synchronous condenser

A technology of ventilation device and camera, which is applied to electromechanical devices, circuit devices, magnetic circuit static parts, etc., can solve the problems of large eddy current loss and local overheating of metal structural parts, so as to improve safe operation performance, reduce temperature difference, solve the The effect of excessive eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

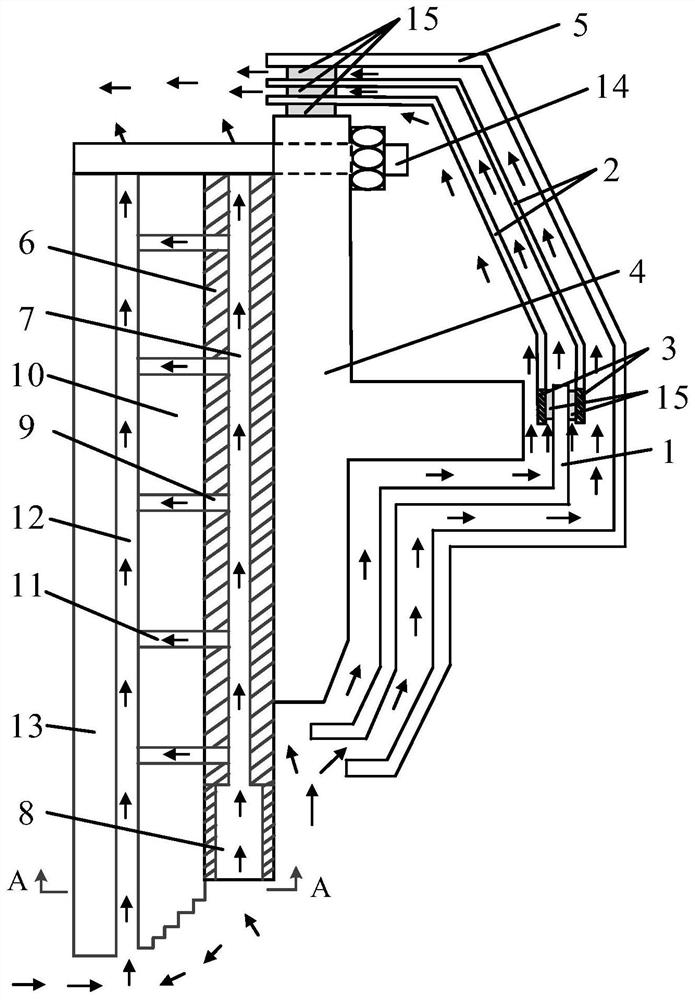

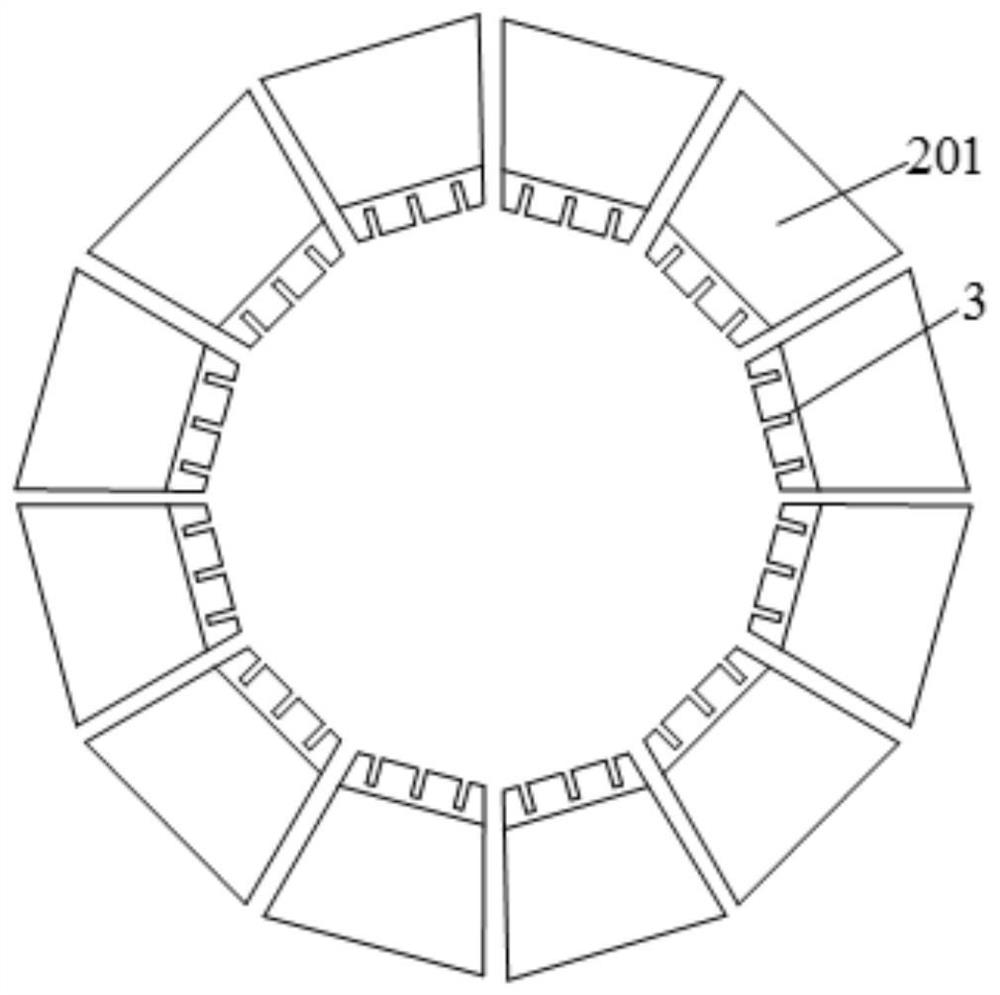

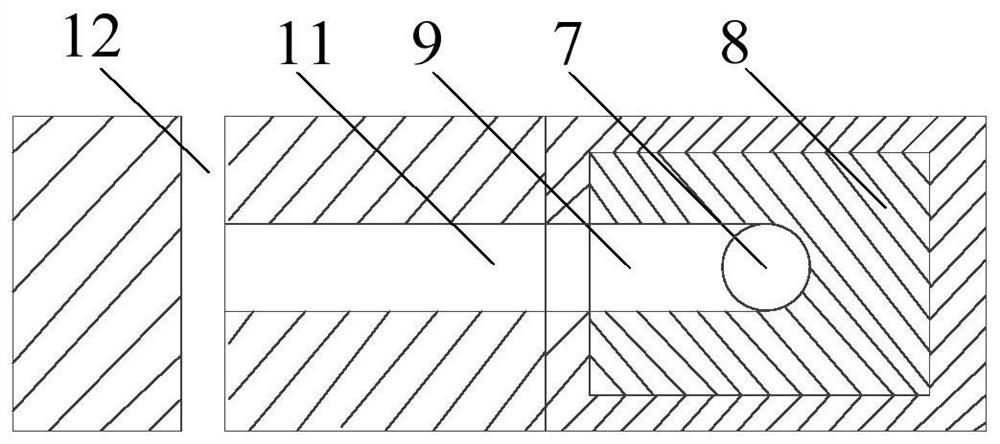

[0031] Such as Figure 1~4 as well as Figure 7 As shown, the present invention provides a large-capacity synchronous condenser end loss reduction ventilation device, which includes a pressure ring 4 and a shielding layer 1. The material of the shielding layer 1 is preferably copper. The iron core 13 at the end of the camera is fixedly connected, and the front of the pressure ring 4 is provided with a double-layer shielding layer 2 in a hollow structure, and the double-layer shielding layer 2 is fixedly connected with the pressure ring 4, such as figure 2 As shown, the double-layer shielding layer 2 is a dome structure with a through hole in the middle, and each layer of the double-layer shielding layer 2 includes 12 fan-shaped shielding layers 201, and a gap is provided between two adjacent fan-shaped shielding layers 201. The width of the double-layer shielding layer 2 is 4-6mm, the gaps on each layer of the double-layer shielding layer 2 do not overlap, the thickness of e...

Embodiment 2

[0036] Such as figure 2 , image 3 , Figure 5 , Figure 7 with Figure 8 As shown, this embodiment is further limited on the basis of Implementation 1. The shape of the bottom ventilation cavity 8 is a circular platform structure, the small end of the bottom ventilation cavity 8 is connected to the middle ventilation cavity 7, and the depth of the bottom ventilation cavity 8 is 140 ~ 180mm, the centerline of the bottom ventilation cavity 8 coincides with the centerline of the middle ventilation cavity 7. The bottom ventilation cavity 8 inside the ventilation pressure finger 6 is in the shape of a truncated cone, which increases the contact area of the bottom ventilation cavity 8, increases the flow rate of the cooling fluid from the bottom ventilation cavity 8 into the middle ventilation cavity 7, and reduces the fluid resistance, which is conducive to better heat dissipation.

Embodiment 3

[0038] Such as figure 2 , Image 6 , Figure 7 with Figure 9 As shown, this embodiment is further limited on the basis of implementation 1. The shape of the bottom ventilation cavity 8 is a rectangular groove structure, the depth of the bottom ventilation cavity 8 is 140-180mm, and the width of the bottom ventilation cavity 8 is 2-4mm; The bottom ventilation cavity 8 is set in a rectangular groove structure, which can better extend the flow path of the induced eddy current, thereby reducing the eddy current loss of the ventilation cavity 8 at the bottom of the ventilation pressure finger 6 and reducing the temperature rise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com