Flue gas waste heat storage device

A heat storage device, flue gas waste heat technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc. Equipment operating efficiency, improving energy utilization, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

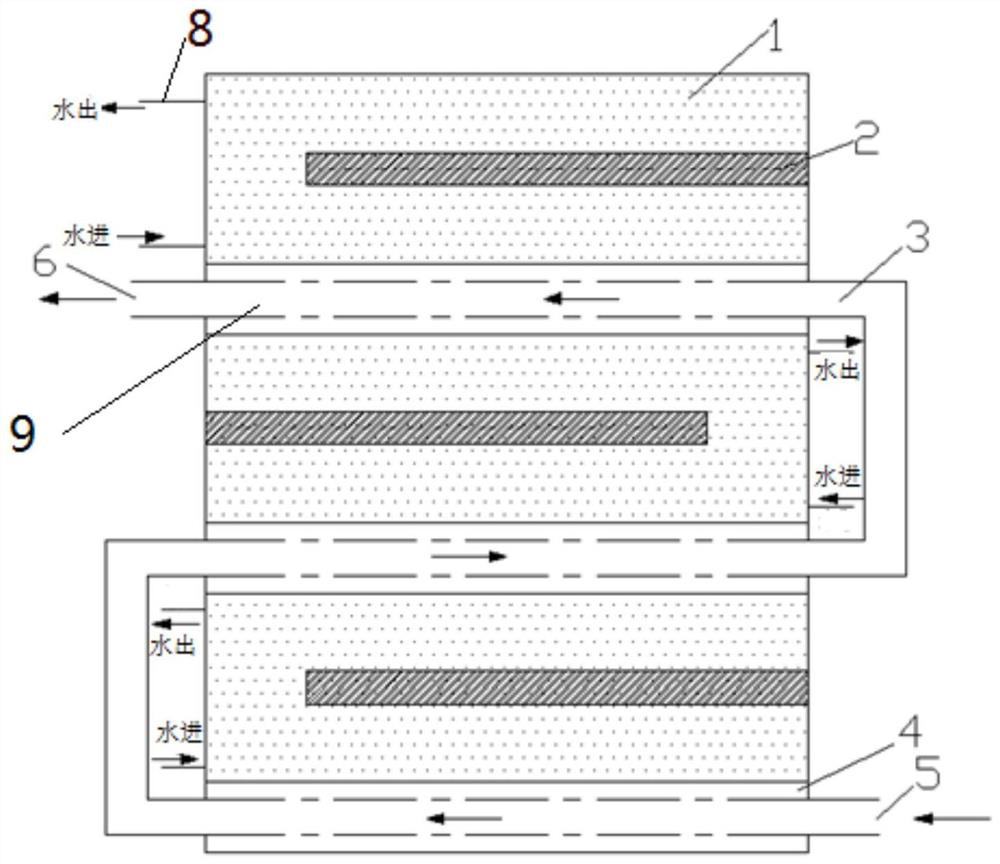

[0052] Such as figure 1 As shown, a preferred embodiment of the present invention provides a flue gas waste heat heat storage device, including:

[0053] A plurality of heat storage units, specifically, three heat storage units in this embodiment.

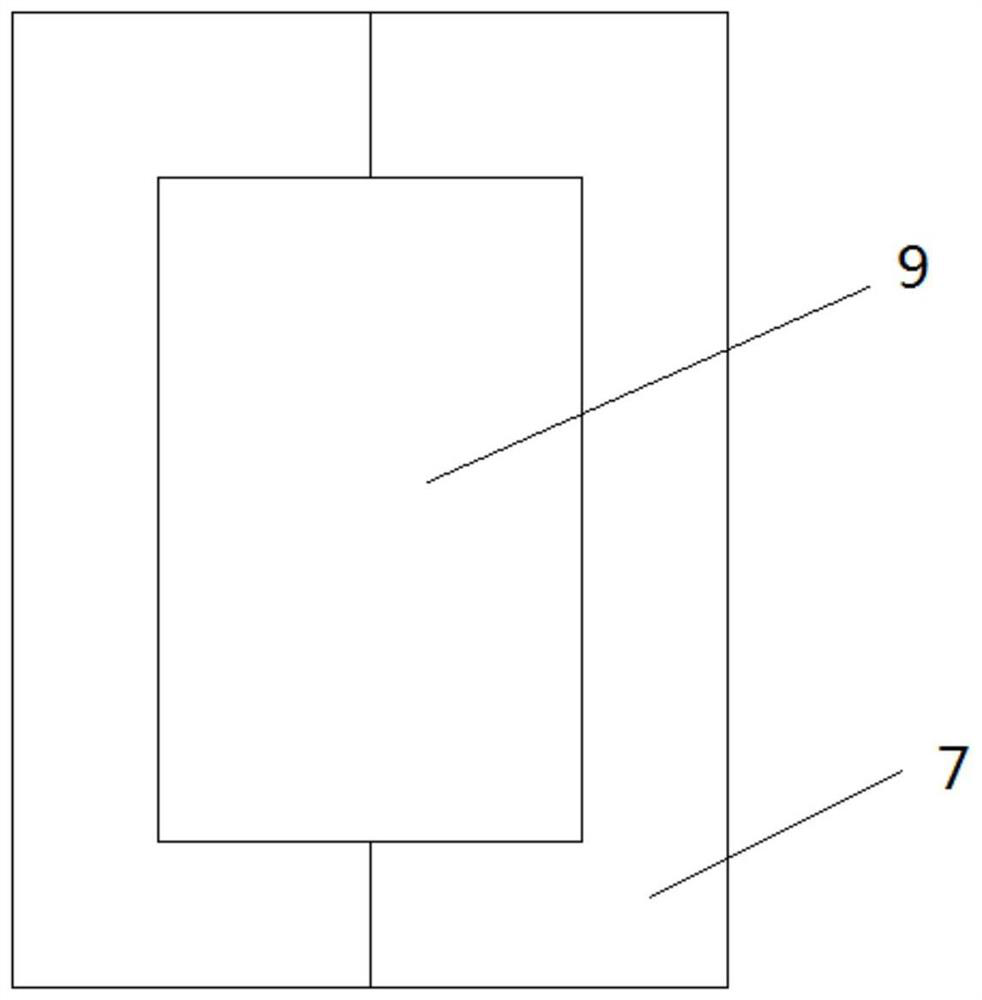

[0054] Wherein, each heat storage unit includes a molten salt heat storage body 1 , a solid heat storage body 4 and a heater 2 . The molten salt heat storage body 1 is composed of a molten salt heat storage material and a molten salt storage tank, and the solid heat storage body 4 is composed of a plurality of solid heat storage bricks 7, forming a hollow flue gas channel 9, and the three heat storage units Combined together to form a whole, the heater 2 is arranged inside the molten salt heat storage body 1 and evenly arranged around it. The solid heat storage body 4 is arranged below the molten salt heat storage body 1 .

[0055] Through such a structure, the traditional large-volume molten salt heat storage body is changed in...

Embodiment 2

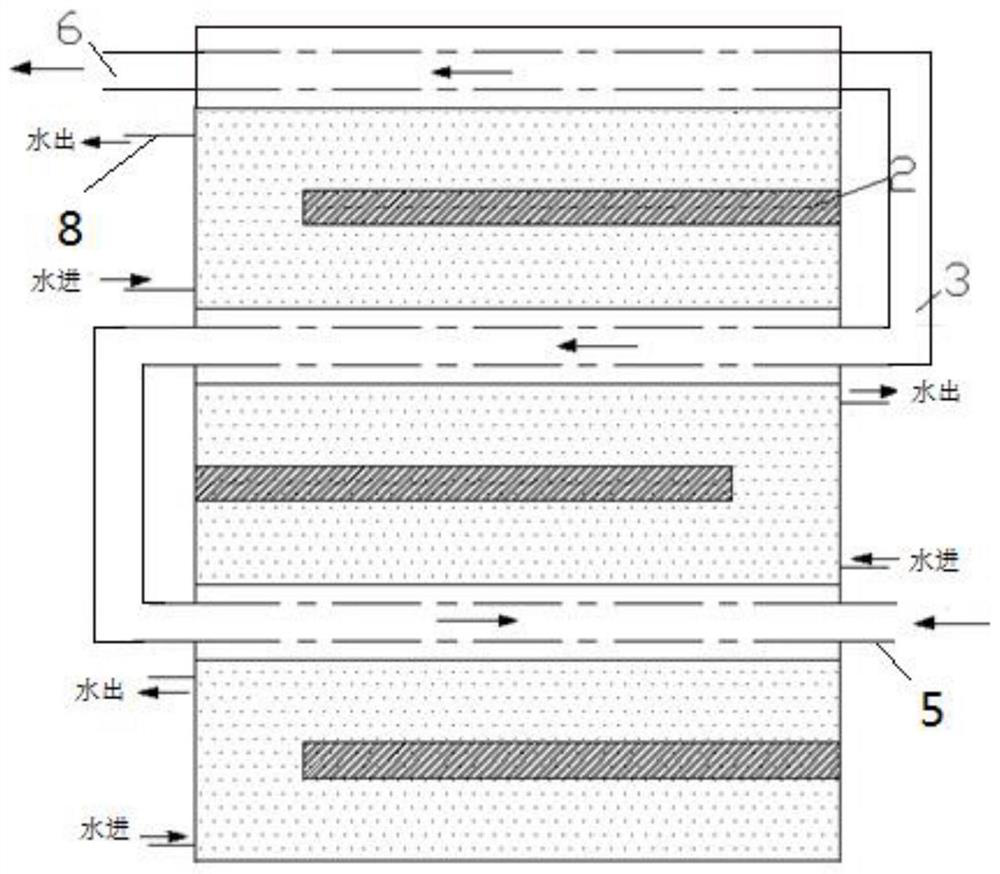

[0072] Such as image 3 As shown, another preferred embodiment of the present invention provides a flue gas waste heat heat storage device. The difference with the above-mentioned embodiment is that:

[0073] Each heat storage unit includes a molten salt heat storage body 1 , a solid heat storage body 4 and a heater 2 , and the solid heat storage body 4 is arranged above the molten salt heat storage body 1 . An electric heater 2 is arranged inside the molten salt heat storage body 1 for supplementing energy, and the heaters 2 are arranged around the molten salt heat storage body 1 .

[0074] In this embodiment, specifically, the heat storage bricks are solid magnesia bricks. Each solid magnesia brick is closely arranged and combined to form a flue gas channel 9 .

Embodiment 3

[0076] Such as Figure 4 As shown, the difference between this embodiment and the above-mentioned two embodiments is that there are multiple flue gas passages 9 composed of solid heat storage bricks 7 in each heat storage unit, and the multiple passages are connected in parallel to enter and exit the heat storage The flue gas pipeline 3 of unit is all one. The flue gas passages 9 passing through the solid heat storage body 4 are all arranged in the heat storage unit. The path of high-temperature flue gas flowing in the flue gas channel 9 is shown in Figure 4 indicated by the middle arrow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com