A process for prolonging the shelf life of supplementary food nutrient supplement food

A nutrient and shelf life technology, which is applied in the field of food processing, can solve problems such as shortening product shelf life and affecting product quality, and achieves the effects of simple operation, prolonging shelf life, and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] (1) Preparation of embedded calcium carbonate, including the following steps:

[0035] 1) Pretreatment of raw materials: prepare one or more vegetable oils such as corn oil, palm oil, soybean oil, and calcium carbonate, heat the vegetable oil to 40-50°C, and set aside;

[0036] 2) Add calcium carbonate to the wet mixing granulator, add 2-12% vegetable oil in proportion to the quality of calcium carbonate, start stirring I, stirring II, chopping II for stirring and chopping for 240 seconds;

[0037] 3) After cleaning the inner wall of the wet mixing granulator and the materials attached to the upper cover, turn on stirring II and chopping I to stir and chop for 300 seconds;

[0038] 4) After cleaning the inner wall of the wet mixing granulator and the materials attached to the upper cover, turn on stirring II, stirring I and chopping I to stir and chop for 180 seconds;

[0039] 5) Release the material into a double-layer polyethylene bag, seal it with a sealing machine ...

Embodiment 1

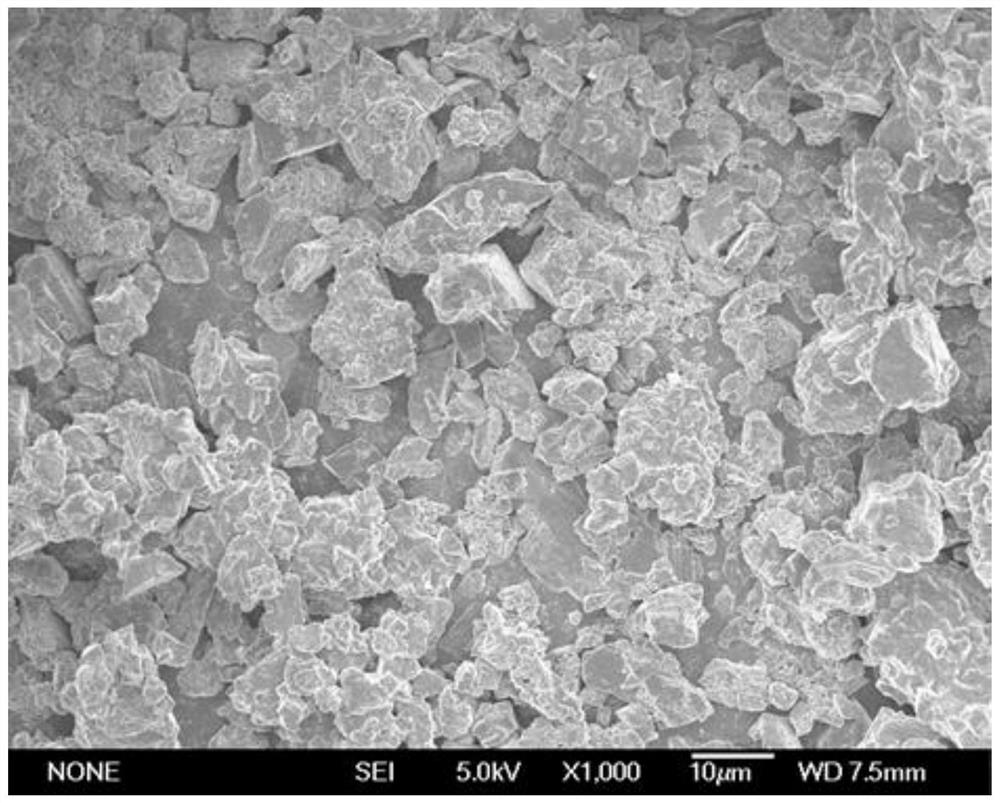

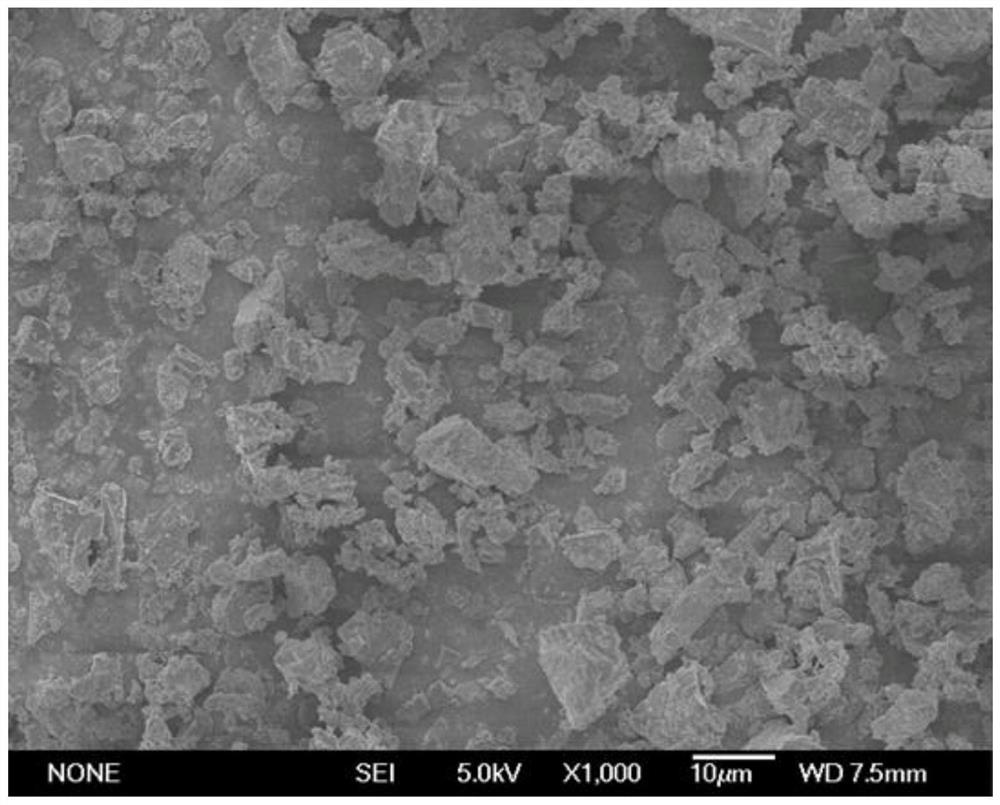

[0043] Example 1 Comparison of scanning electron microscope images of embedded calcium carbonate and unembedded calcium carbonate

[0044] see Figure 1~2 , under the scanning electron microscope, it can be seen that the particle size of the unembedded calcium carbonate is different, and the distance between the particles is relatively large; after embedding, the particle size distribution of calcium carbonate gradually becomes uniform, and after vegetable oil A certain degree of agglomeration occurs between the calcium carbonate particles, so that the embedded calcium carbonate is not easy to have a hala taste due to moisture.

Embodiment 2

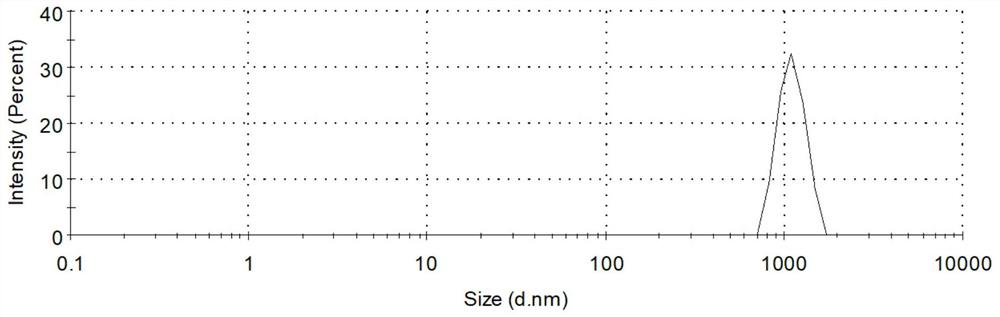

[0045] The particle size distribution figure of embodiment 2 various nutrients

[0046] Various nutrients added in the process of the present invention (calcium carbonate, sodium iron edetate, ferrous fumarate, zinc oxide, vitamin A palmitate, vitamin D 3 , Vitamin B 1 , Vitamin B 2 , Vitamin B 12 , folic acid) particle size distribution such as Figure 3-12 As shown, the Z-average and PDI of each nutrient are shown in Table 1.

[0047] Table 1 Z-average and PDI of each nutrient

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com