Complete-air-throwing air separation system

A sub-system and complete technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve problems such as belt deviation faults, large volume of air separation equipment, and wind field disorder. Achieve the effect of reducing high-speed rotating parts, reducing equipment complexity, and reducing material crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

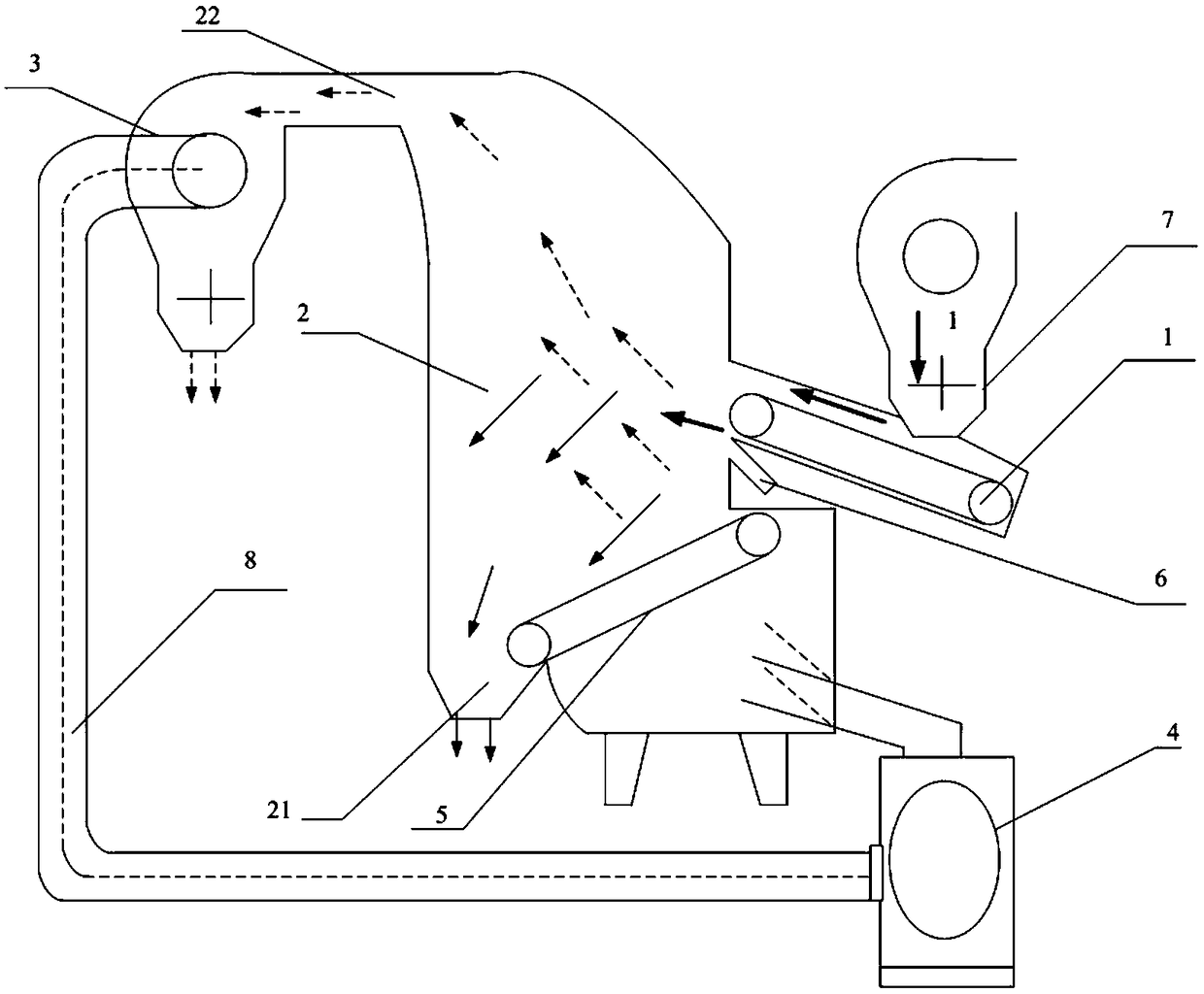

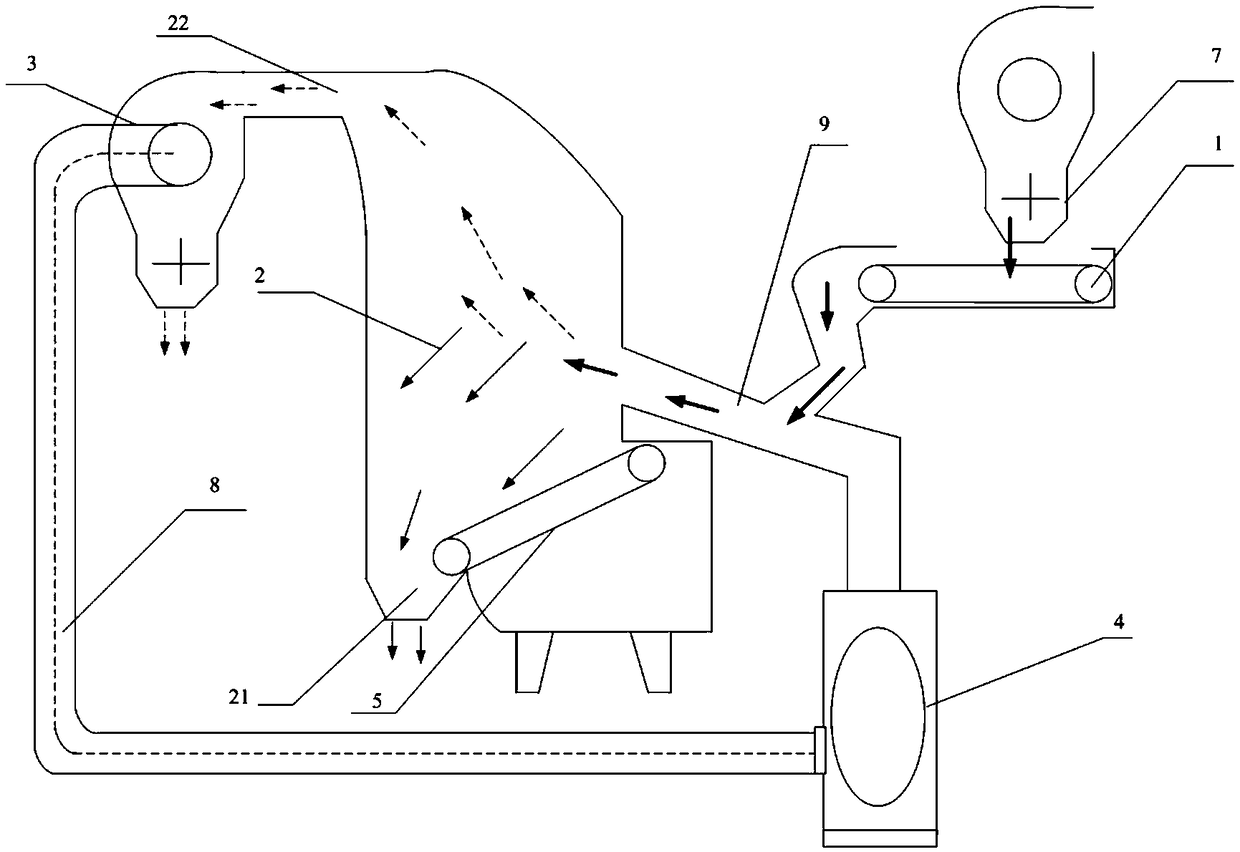

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0030] The specific equipment structure will not be described in detail. Now, taking the separation process of shredded tobacco and stem sticks common in the tobacco industry as an example, the working process of the equipment of the present invention will be introduced in detail:

[0031] The solid material is a mixture of shredded tobacco and stem sticks, wherein shredded tobacco is a light material and the stem stick is a heavy material. The solid material is input from the first rotary belt feeder 1 to the feed inlet 91 of the air throwing pipe 9. Since the circulating fan used in this paper is a negative pressure fan, the outlet air of the negative pressure fan is in the air distribution bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com