Automobile part washing production line and washing method

A technology for auto parts and production lines, which is applied in the field of auto parts processing, and can solve problems such as incomplete cleaning, affecting the appearance and use experience of auto parts, and easy adhesion of oil stains to other accessories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

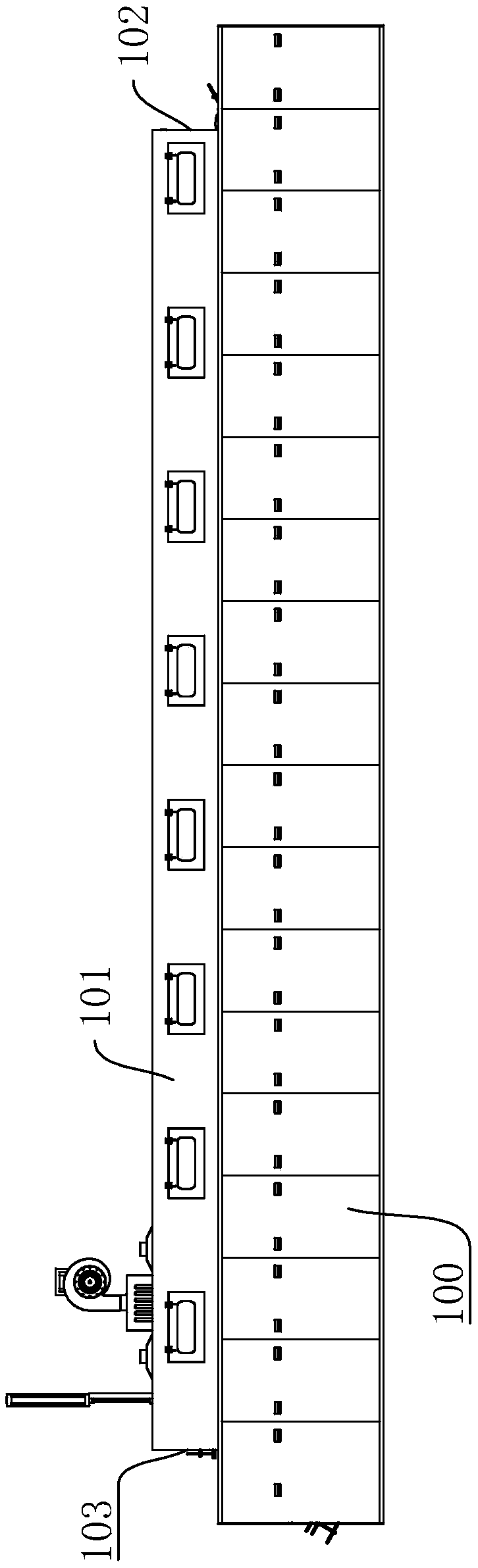

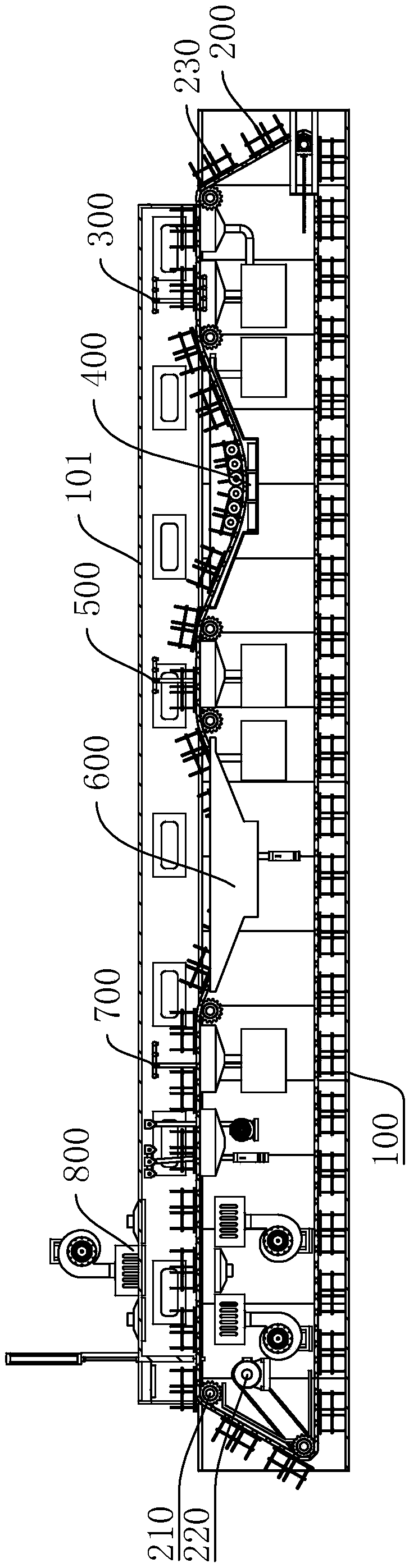

[0056] Embodiment: a kind of auto parts cleaning production line, such as figure 1 with 2 As shown, it includes a base 100, the base 100 is covered with a hood 101, the front and rear ends of the hood 101 are respectively provided with an inlet 102 and an outlet 103, and the base 100 is provided with a conveying device 200 for transporting auto parts along its length. The base 100 is provided with a spray cleaning assembly 300, an ultrasonic cleaning assembly 400, a clear water spray rinsing assembly 500, a bubbling cleaning assembly 600, a pure water spray rinsing assembly 700 and an air-drying device 800 along the conveying direction of the auto parts.

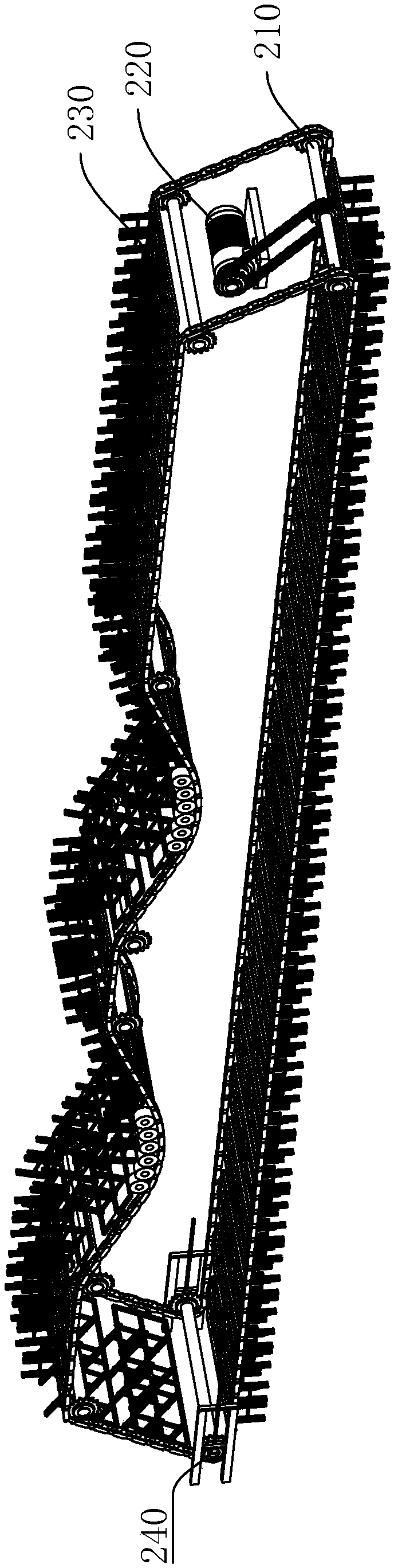

[0057] Such as figure 2 As shown, the conveying device 200 includes a conveying mechanism 210 and a driving mechanism 220 for driving the conveying mechanism 210 , and the conveying mechanism 210 is also provided with a clamping mechanism 230 for clamping automobile parts.

[0058] Such as Figure 4 As shown, the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com