Multifunctional glass washing device

A glass cleaning and cleaning device technology, which is applied in the direction of cleaning flexible objects, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as long payback time, high capital requirements for enterprises, labor-intensive and time-consuming manual scrubbing, etc. Achieve the effect of easy to move and carry, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

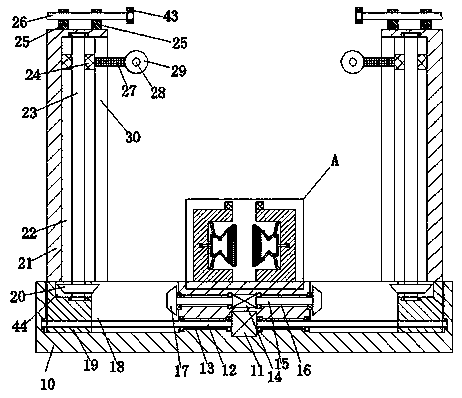

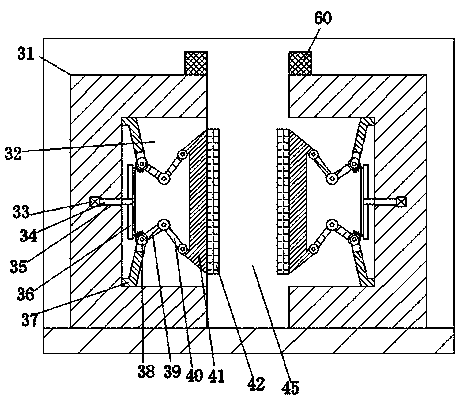

[0013] like Figure 1-Figure 2 As shown, a multifunctional glass cleaning device of the present invention includes a device main body 10, a cleaning device arranged in the device main body 10, and a clamping device arranged in the device main body 10. The cleaning device includes a fixed The first motor 11 arranged in the device main body 10, the left and right sides of the first motor 11 and the first cavity 13 are arranged in the device main body 10, the first cavity 13 is far away from the first One end of a motor 11 is communicated with a second cavity 18 with an upward opening, and the left and right ends of the first motor 11 are power-fittingly connected with a motor extending through the first cavity 13 and extending into the second cavity 13. The first rotating shaft 12 in the cavity 18, the end of the first rotating shaft 12 away from the first motor 11 is rotatably connected to the inner wall of the second cavity 18 through a bearing, and the second cavity 18 A fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com