A water-cooled middle shell and its casting process

A water-cooling and casting mold technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problem of high proportion of water-cooled middle shell choking defects, and achieve the effect of solving low yield and reducing casting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A water-cooled middle shell

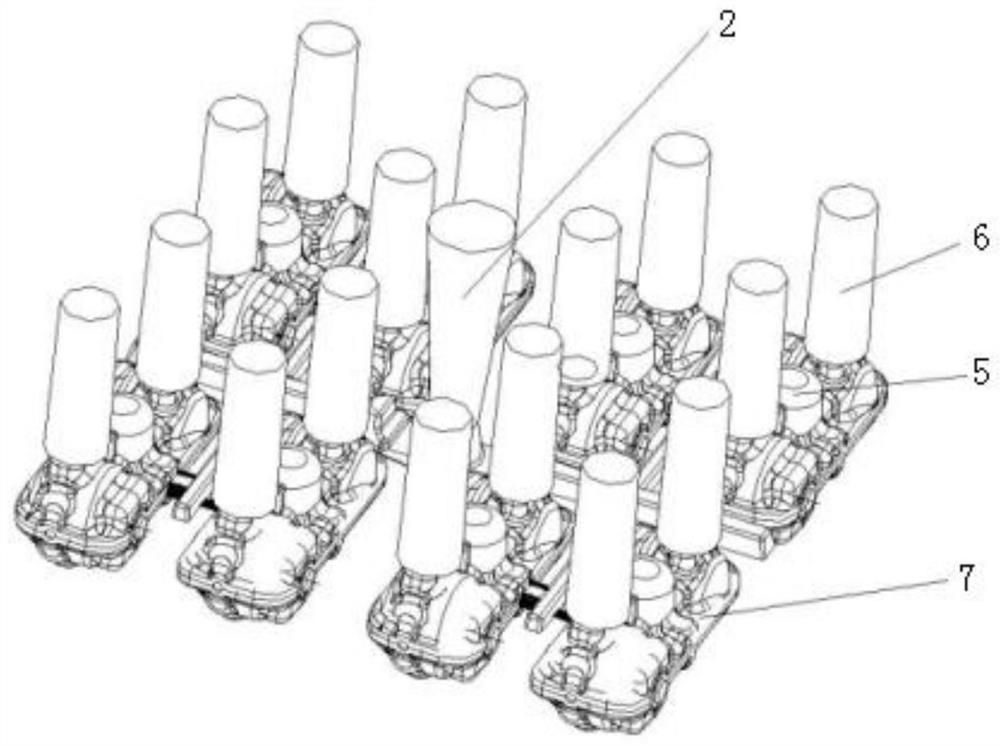

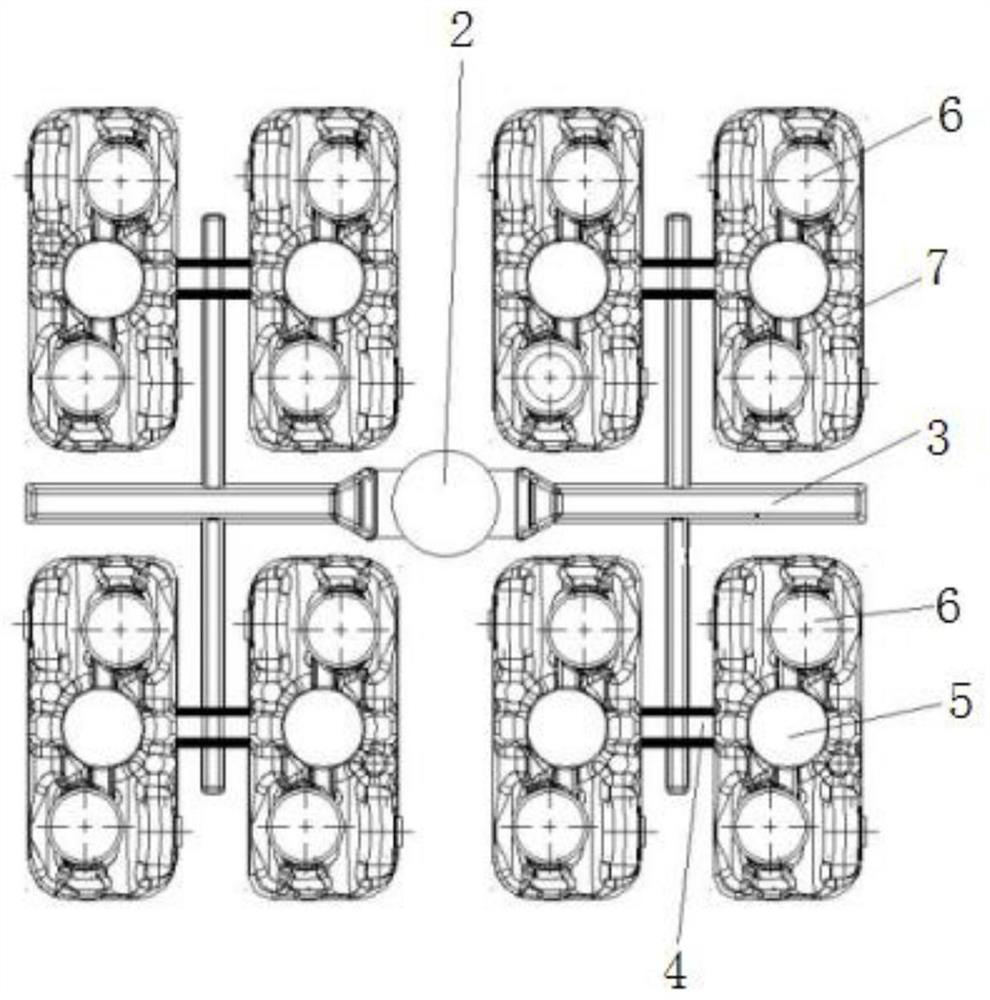

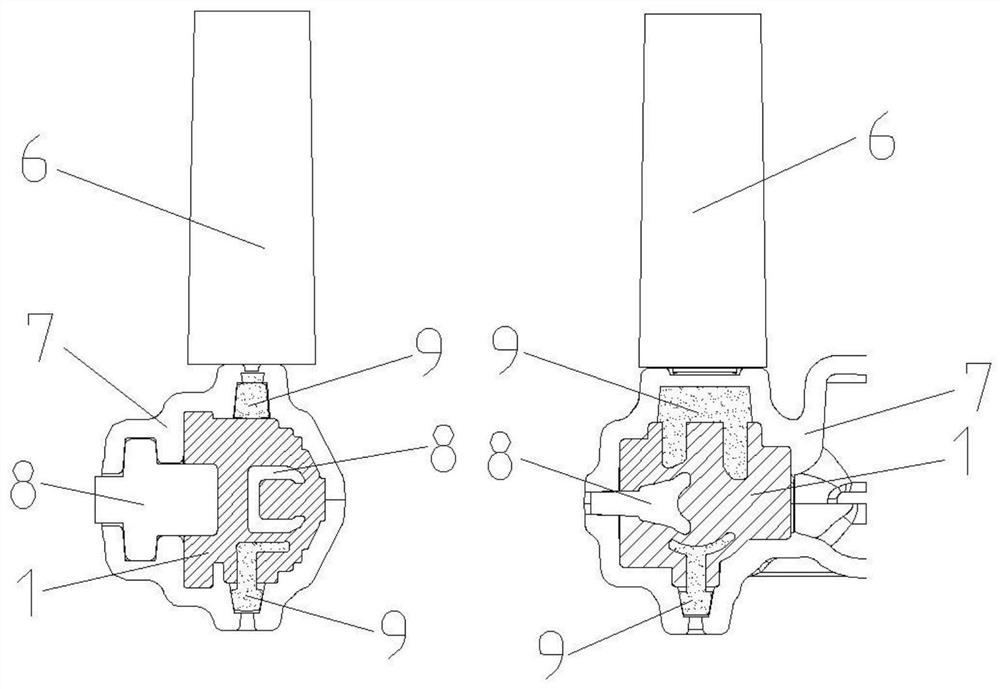

[0029] Such as figure 2 As shown, the present invention provides a water-cooled intermediate shell, including an intermediate shell casting 1, a sprue 2, a runner 3, an inner sprue 4, a riser 5, an air collecting bag 6, an outer sand shell 7, and an oil chamber core 8, water cavity core 9;

[0030] The sprue 2 is arranged at the center of the template and is perpendicular to the ground, and one sprue 2 is provided.

[0031] The runner 3 is arranged symmetrically on both sides of the sprue 1 and parallel to the ground,

[0032] The sprue 2 is connected to the runner 3, and the runner 3 is connected with a plurality of inrunners 4, and the inrunner 4 is connected to the riser 5, and the riser 5 is connected to two intermediate shell castings 1. The riser 5 and the two intermediate shell castings 1 are placed in the outer sand shell 7, and two air collection bags 6 are arranged on the top of the outer sand shell 7.

[0033] T...

Embodiment 2

[0040] Embodiment 2 Casting process of a water-cooled middle shell

[0041] The invention provides a casting process for a water-cooled turbine shell, comprising the following steps:

[0042] Step S1: setting the sprue 2 at the center of the template and perpendicular to the ground;

[0043] Step S2: The runner 3 is arranged symmetrically on both sides of the sprue 2 and parallel to the ground, and the sprue 2 is connected to the runner 3;

[0044] Step S3: the runner 3 is connected with a plurality of ingates 4, and the ingates 4 are connected to the riser 5;

[0045] Step S4: The riser 5 connects the two middle shell castings 1, and the riser 5 and the two middle shell castings 1 are placed in the outer sand shell 7;

[0046] Step S5: Inject molten iron from the sprue 2 during pouring. The molten iron flows through the runner 3 and enters the cavity of the riser 5 through the inrunner 4. The molten iron in the riser 5 enters the two intermediate The cavity of the shell ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com