Pre-punching, draining and chip discharging method for electrical discharge machining of enclosed integral blade disc

A technology of integral blisk and electric discharge, applied in the field of electric discharge machining, can solve problems such as unstable discharge state, low processing efficiency of closed integral blisk, and poor discharge of discharge erosion products, so as to improve processing efficiency and achieve highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

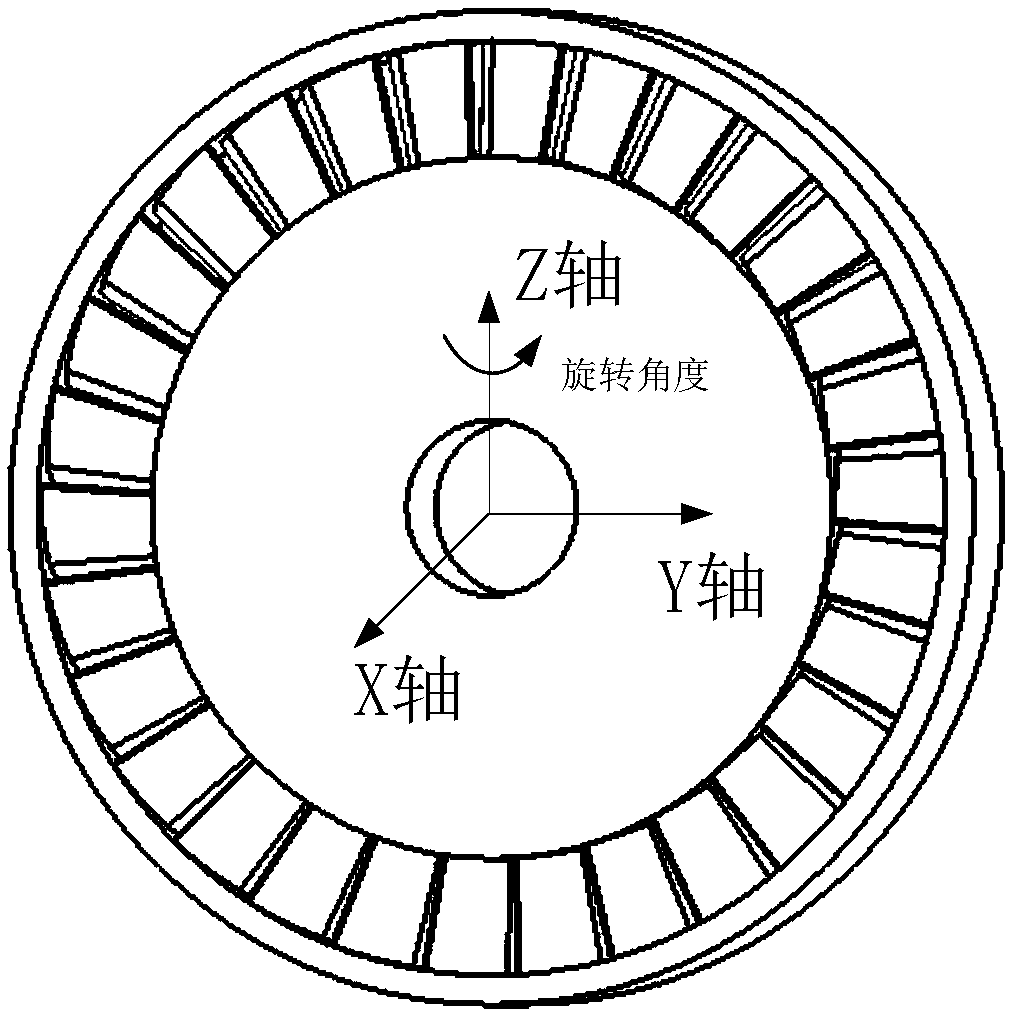

[0027] Such as figure 1 As shown in , the closed integral blade disk to be processed is rotated around the Z axis, and the rotated blade disk is projected onto the YZ plane, and the Z-axis rotation angle under the condition of the largest flow channel area on the projection surface is selected as the pre-hole angle. In this embodiment, the pre-hole angle is -15°.

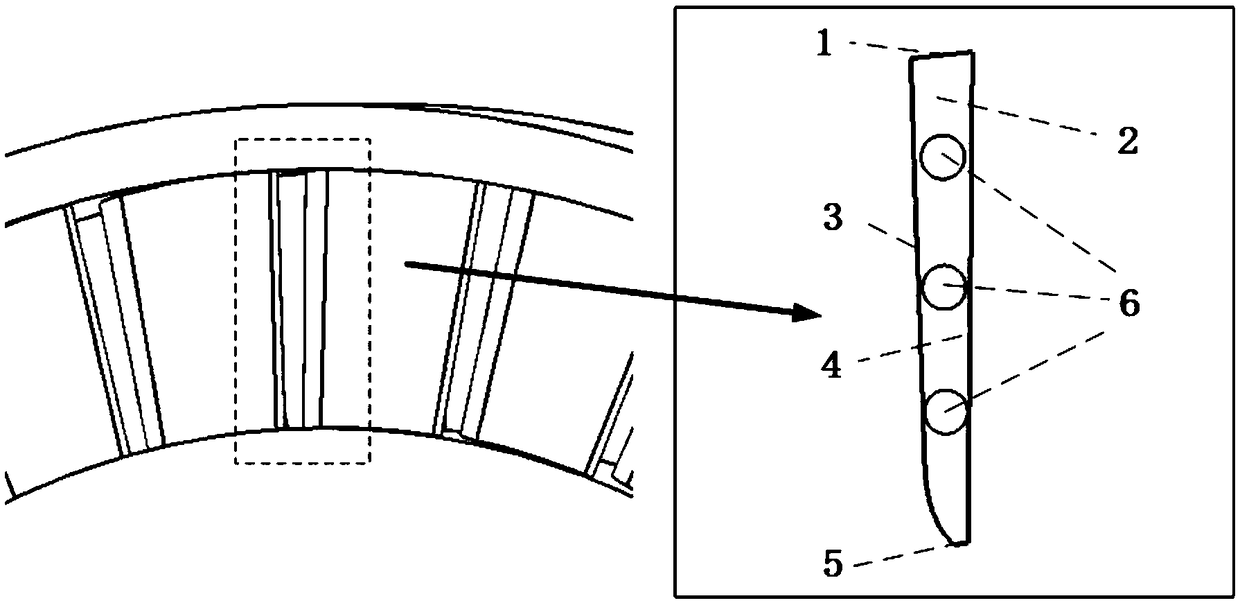

[0028] Such as figure 2 As shown, under the condition that the projected area of the runner area is the largest, the diameter of the pre-hole is selected according to the distance between the projected boundaries of the left and right blades and the size range of the copper tube electrode of the high-speed EDM machine tool. In this embodiment, the diameter of the pre-hole is 1.8 mm. According to the distance between the leaf crown and the leaf bottom, the number of pre-holes in this embodiment is 3.

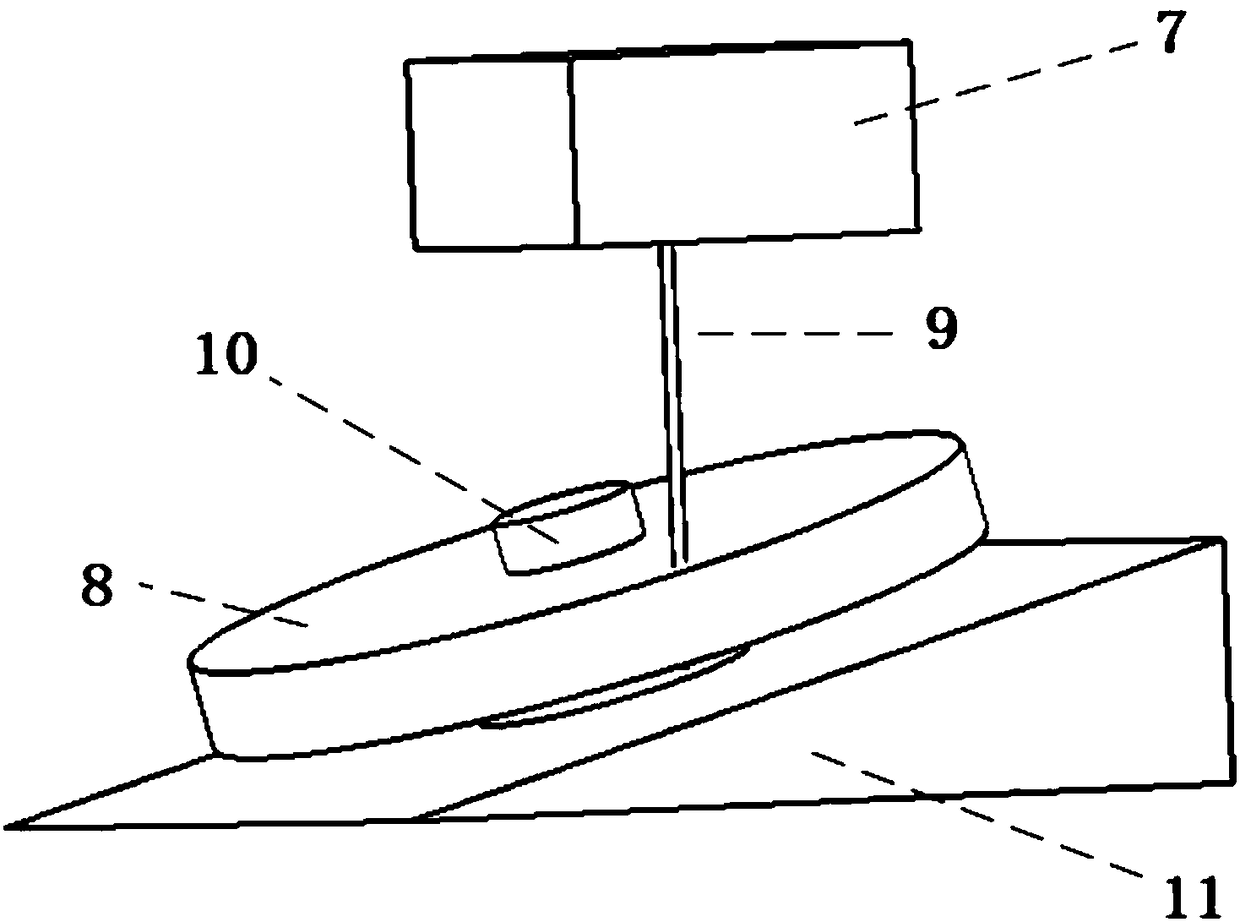

[0029] Such as image 3 As shown, adjust the inclination angle of the jig according to the designed pre-hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com