High-precision positioning and mounting method applied to heavy machinery columns and construction steel structures in large space

A heavy machinery, positioning and installation technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high processing and installation positioning accuracy, and achieve the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] The preferred specific implementation method of the high-precision positioning and installation method of the large-space heavy machinery column and the building steel structure of the present invention is:

[0025] Include steps:

[0026] A. Measure the positioning datum on the steel structure foundation;

[0027] B. Milling the mounting surface of the mechanical column;

[0028] C. Processing positioning key;

[0029] D. The positioning key is adjusted to determine the baseline;

[0030] E. Use laser tracker, electronic theodolite and dial indicator to cooperate with three precision measuring instruments to measure and adjust the positioning key;

[0031] F. The positioning key is fixed;

[0032] G. Install the mechanical column.

[0033] In the step A, the steel structure foundation is welded and assembled, and the position of the positioning key keyway as the positioning reference is shifted with the welding deformation of the steel member, and the laser tracke...

specific Embodiment

[0050] 1 Measuring the positioning datum on the steel structure foundation

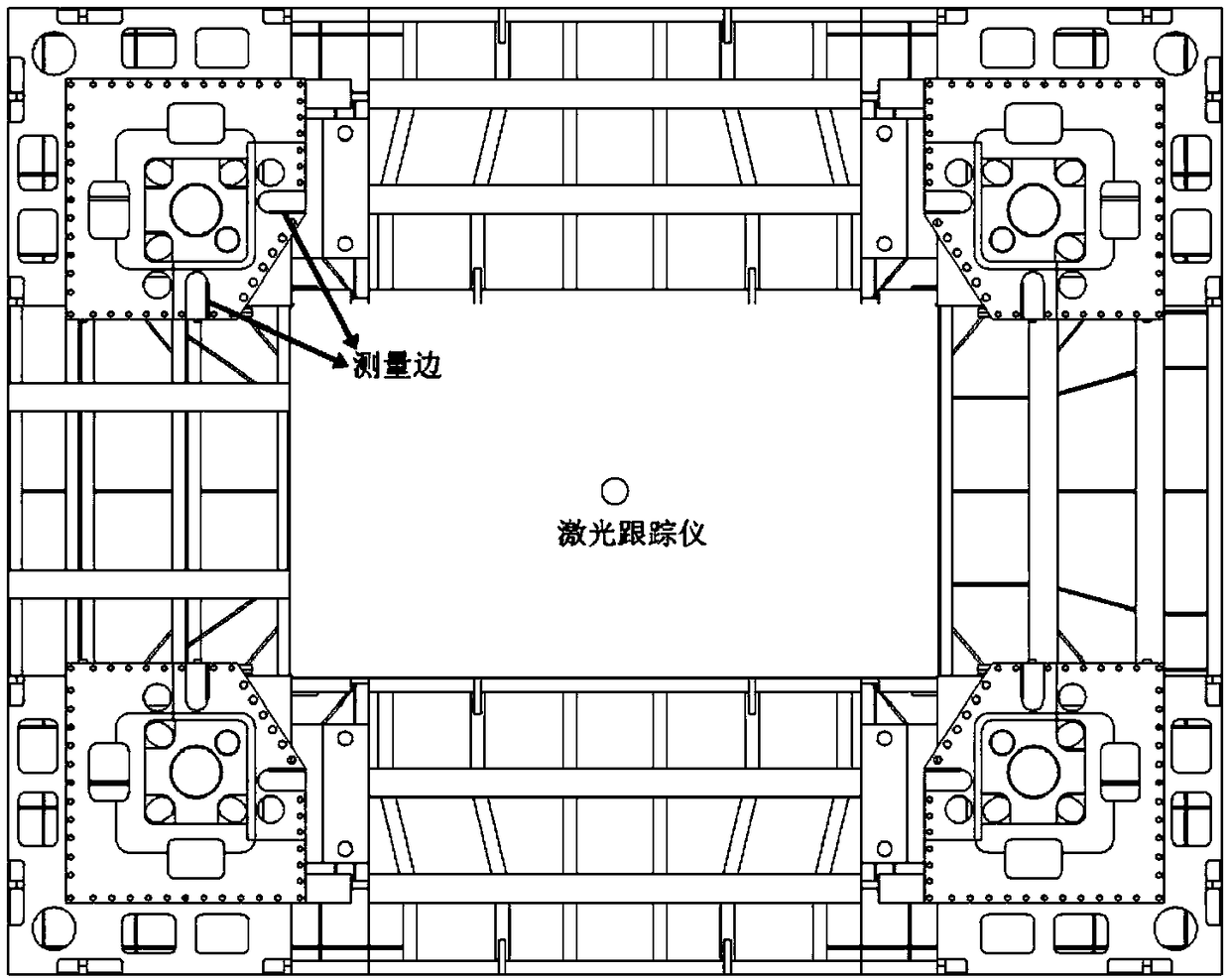

[0051] Due to the welding and assembly of the steel structure foundation, the position of the positioning reference (keyway) shifts with the welding deformation of the steel member. The laser tracker is used to measure the position of the keyway on the steel structure foundation and the flatness of the installation plane of the mechanical column, such as figure 1 shown.

[0052] 2 Milling mechanical column mounting surface

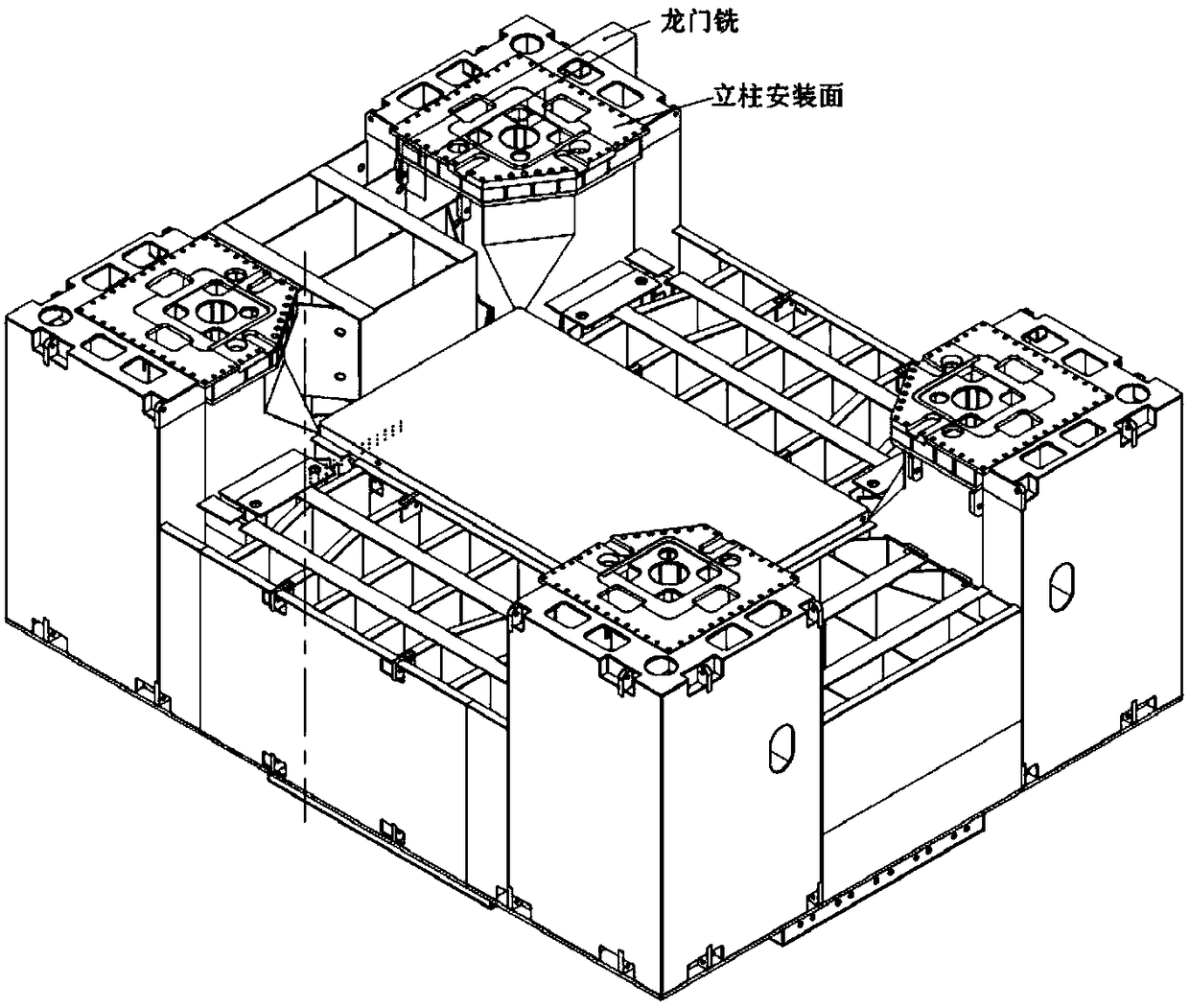

[0053] Set up a gantry milling machine on site to mill the installation surface of the mechanical column to make the flatness reach 0.1mm / m. The height difference of the installation surfaces of the four mechanical columns is not more than 0.1mm, and the milling process is as follows: figure 2 shown.

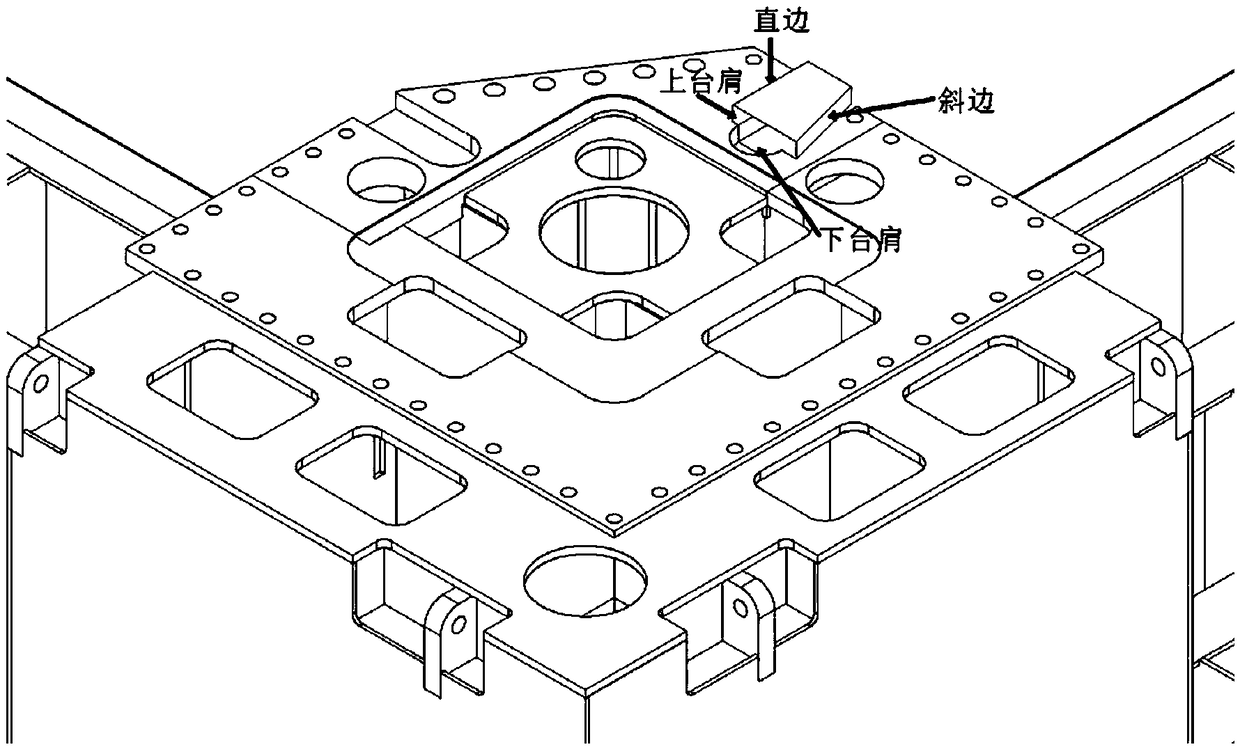

[0054] 3 processing positioning key

[0055]According to the measurement results of the position offset of the keyway of the positioning key and the analysis of the data, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Parallelism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com