Metal part crack opening method

A technology of metal parts and opening methods, which is applied in the field of failure analysis of metal material failure parts, can solve the problems of fracture damage, inability to perform specific operations and specifications according to this, and achieve the effect of reducing fracture damage and facilitating the failure analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

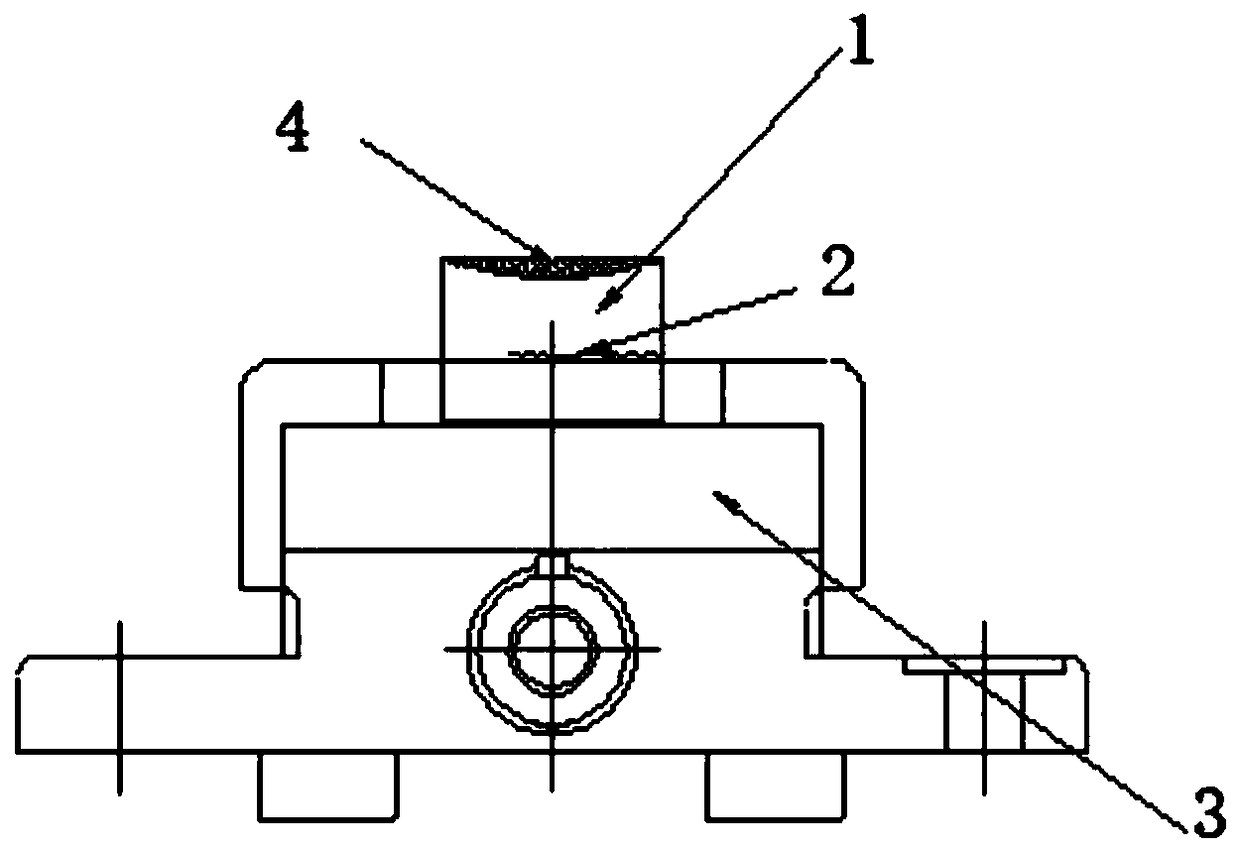

[0034] A method for opening a crack in a metal part. The present embodiment is a metal thin-walled part. The specific steps are as follows:

[0035] (1) Cutting: First cut around the crack of the metal thin-walled part. When cutting parallel to the crack, it should be as far away from the crack as possible. At the same time, the cutting distance should be 20mm-50mm, leaving the knocking part for the subsequent fracture opening; The cutting position perpendicular to the crack should be as close to the crack position as possible, and the distance between the crack and the crack should be 3mm to 5mm;

[0036] (2) Clamping: Clamp the metal thin-walled parts on the bench vise, the crack is parallel to the clamping surface of the bench vise, and the crack must not contact the bench vise;

[0037] (3) Keep the distance: the crack should be close to the end face of the bench vise and kept at 3mm to 5mm; the surface of the part at the parallel crack should be selected during clamping, ...

Embodiment 2

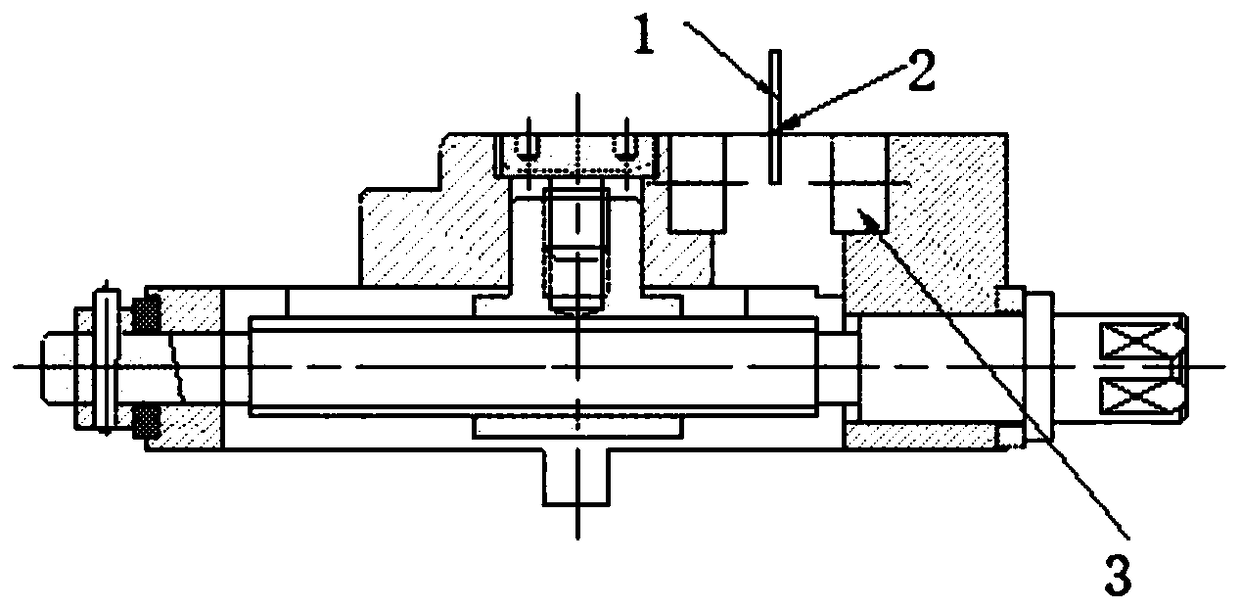

[0043] A method for opening a crack in a metal part. The present embodiment is a metal thick-walled part. The specific steps are as follows:

[0044] (1) Cutting: First cut around the crack of the metal thick-walled part. When cutting parallel to the crack, it should be as far away from the crack as possible. At the same time, the cutting distance should be 20mm-50mm, leaving the knocking part for the subsequent fracture opening; The cutting position perpendicular to the crack should be as close to the crack as possible, and the distance between the crack and the crack should be 3mm to 5mm. If the crack of the thick-walled part is shallow, it needs to be cut in the reverse direction. The deepest part of the cutting position should be no less than the depth of the crack. less than 3mm to avoid damage to the fracture;

[0045] (2) Clamping: Clamp the part on the bench vise, the crack is parallel to the clamping surface of the bench vise, and the crack must not be in contact with...

Embodiment 3

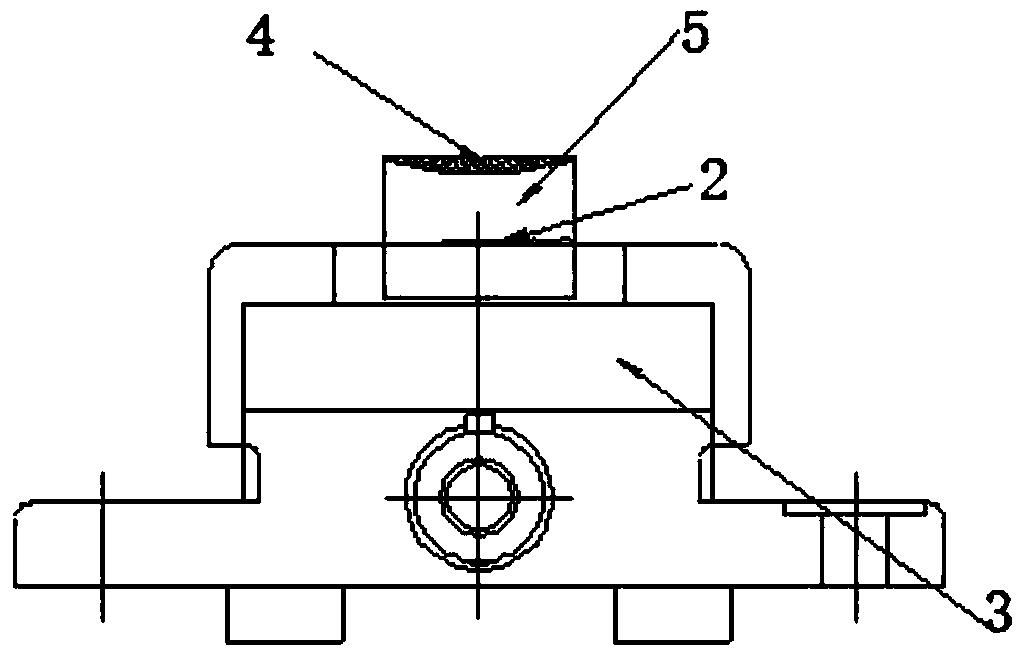

[0053] A method for opening a crack in a metal part. This embodiment is a metal columnar part. The specific steps are as follows:

[0054] (1) Cutting: First cut around the crack of the metal columnar part, and cut parallel to the crack. It should be as far away from the crack as possible, and the distance should be kept at 20mm to 50mm, leaving the percussion part for the subsequent fracture opening; such as thick wall Parts with shallow cracks need to be cut on the reverse side. The deepest part of the cutting position should not be less than 5mm from the edge of the crack to avoid damage to the fracture;

[0055] (2) Clamping: clamp the metal columnar part on the bench vise, the crack is parallel to the clamping surface of the bench vise, the crack must not be in contact with the bench vise, but the crack must be close to the end face of the bench vise;

[0056] (3) Keep the distance: it is advisable to keep the distance between 3mm and 5mm; the surface of the part at the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap