Continuous fiber toughened ceramic matrix composite material additive manufacturing device and manufacturing method thereof

A technology of toughening ceramics and continuous fibers, which is applied in the field of additive manufacturing to achieve the effects of reducing defects, ensuring precision and high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

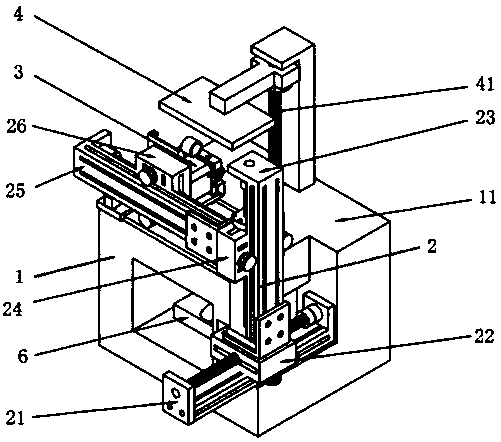

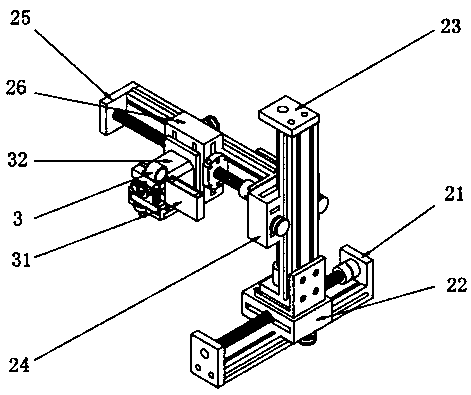

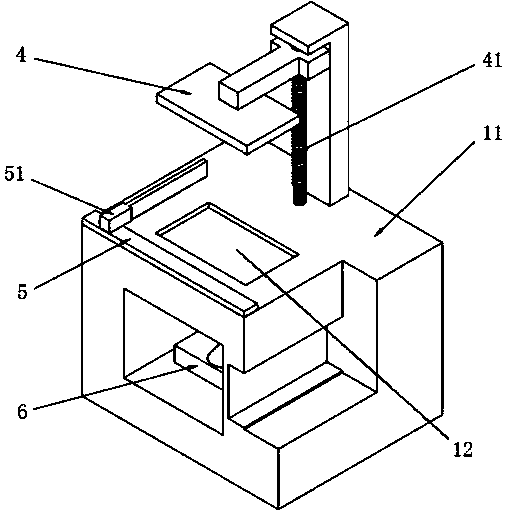

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] The continuous fiber toughened ceramic matrix composite material additive manufacturing device of the present invention includes a seat frame 1, a working surface 11 is arranged on the upper surface of the seat frame 1, a material forming area 12 is arranged on the working surface 11, and the seat frame 1 is fixed There is a three-dimensional space mobile frame 2, and the three-dimensional space mobile frame 2 includes X guide rail 21, X adapter plate 22, Y guide rail 23, Y adapter plate 24, Z guide rail 25 and Z adapter plate 26, X guide rail 21 , Y guide rail 23 and Z guide rail 25 install respective driving motors, Z guide rail 25 is fixed on the seat frame 1, and Z adapter plate 26 can slide on Z guide rail 25 under the drive of Z guide rail drive motor, The Y guide rail 23 is fixed on the Z adapter plate 26, the Y adapter plate 24 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com