System and method for machining microcircuit on surface of carbon-based polymer by using femtosecond laser

A carbon-based polymer and femtosecond laser technology, applied in the field of femtosecond laser applications, can solve problems such as difficult to meet the needs of microcircuits, reduce the capacitance of supercapacitors, and affect the integration of microcircuits, so as to reduce the risk of conduction failure , Edge burr suppression, electrode gap reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

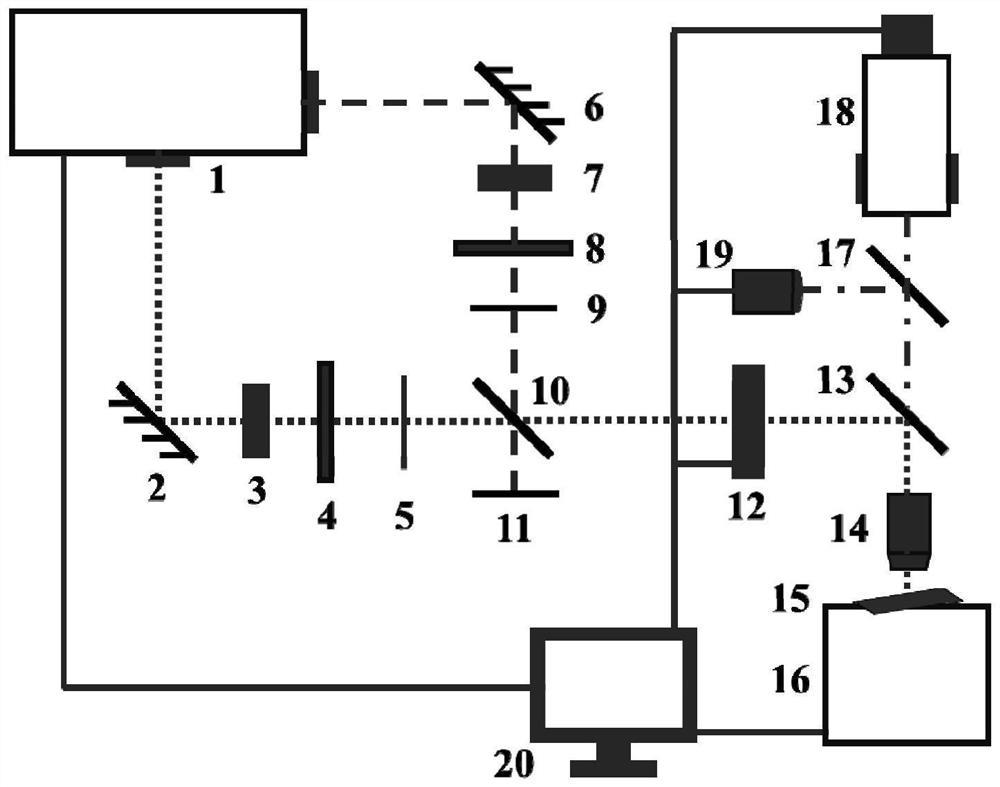

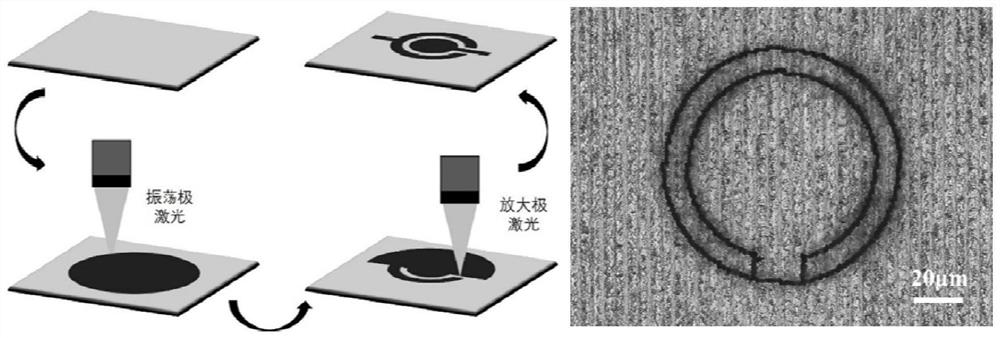

[0033] The circular supercapacitor electrode is machined on the surface of the carbon-based polymer, first opening the femtosecond laser 1 generates femtosecond laser light, and adjusts the oscillation grade laser spot diameter of 5 mm by the first dripper 3, and the first attenuation piece 4 regulates the oscillation level laser power. 20MW, adjusting the extensive laser spot diameter of 5 mm by the second phenostot 7 adjustment, the second attenuation piece 8 adjusts the magnification laser flux is 1.2J / cm 2 The height of the adjustment changing table 16 causes femtosecond laser focusing on the surface of the carbon-based polymer sample 15, and the imaging system is adjusted to clearly imaging. The translational speed of the pan 16 is set to 1000 μm / s, and the optical path of the amplifying stage laser is blocked using the second retaining plate 9, and the control of the electric control shutter 12 outputs the oscillation level laser, and the translation path is designed acc...

Embodiment 2

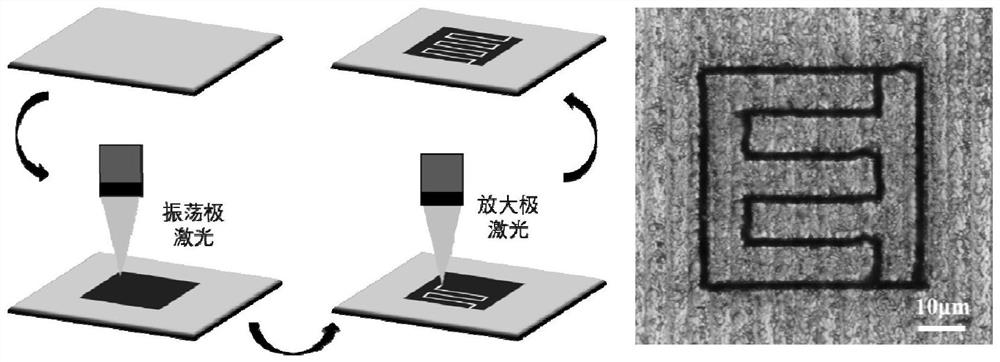

[0036] In the surface of the carbon-based polymer, a fork-finger supercapacitor electrode is first opened, and the femtosecond laser 1 generates femtosecond laser, and the oscillation grade laser spot diameter is 5mm by the first phenostap 3, and the first attenuation piece 4 regulates the oscillation level laser power. 20MW, adjusting the diameter of the laser spot in the diameter of 5 mm, the second attenuation piece 8 adjusts the magnification of 1.2J / cm 2 The height of the adjustment changing table 16 causes femtosecond laser focusing on the surface of the carbon-based polymer sample 15, and the imaging system is adjusted to clearly imaging. The translational speed of the translational stage 16 is 1000 μm / s, and the optical path of the amplified stage laser is blocked using the second retaining plate 9, and the control shutter 12 outputs the oscillation level laser, and the overall outer contour of the fork finger electrode is translated. The path such that the laser focus...

Embodiment 3

[0039] The micro-parallel resistance is machined on the surface of the carbon-based polymer, first opening the femtosecond laser 1 to generate femtosecond lasers, and adjust the oscillation grade laser spot diameter of 5 mm by the first phenadene 3, and the first attenuation piece 4 adjusts the oscillation level laser power of 20 mW. Adjusting the diameter of the amplification of the laser spot in the diameter of 5 mm, the second attenuation piece 8 adjusts the magnification of 1.2J / cm 2 The height of the adjustment changing table 16 causes femtosecond laser focusing on the surface of the carbon-based polymer sample 15, and the imaging system is adjusted to clearly imaging. The translational speed of the changing table 16 is 1000 μm / s, and the optical path of the amplifying stage laser is blocked using the second retaining plate 9, and the control shutter 12 outputs the oscillation level laser, and the translation path is designed according to the overall outer contour of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com