Fine wire circuit and its preparation method

A wire circuit, fine technology, applied in the direction of printed circuit manufacturing, printed circuit, conductive pattern formation, etc., can solve the problems of resource consumption, waste water pollution environment, material consumption, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a fine conductive circuit, comprising the steps of:

[0034] Step 1: configure the slurry, the slurry includes metal ions and reducing agents; it can be understood that it can also include viscosity modifiers, antioxidants and solvents;

[0035] Step 2: performing surface treatment on the substrate material to be coated with slurry to enhance the bonding force between the substrate material and the metal wire (optional step);

[0036] Step 3: irradiate the slurry with laser to make the reducing agent react with metal ions to form fine lines;

[0037] Step 4: cleaning and removing the unreacted slurry;

[0038] Step 5: Thicken the formed fine circuit by electroplating or electroless plating to form a final circuit pattern (an optional step).

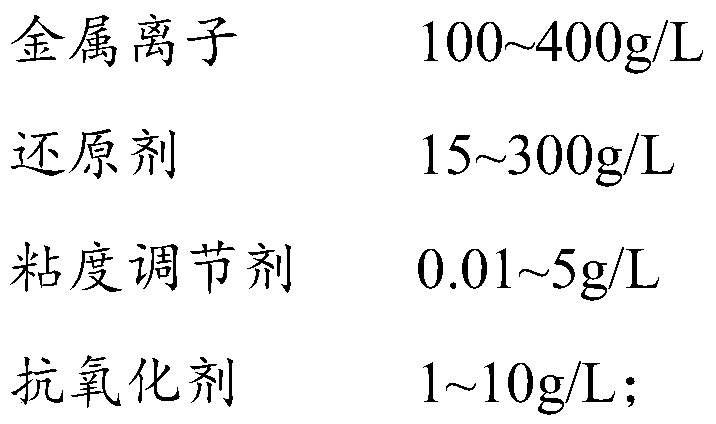

[0039] The slurry in step 1 mainly comprises metal ion compound, reducing agent and auxiliary materials such as viscosity regulator, antioxidant and solvent.

[0040] The metal ion comprises the following ...

Embodiment 1

[0054] Use the mixed slurry of copper acetate monohydrate and acetic acid to make fine wire lines, and the specific steps are as follows:

[0055] (1) Use copper acetate monohydrate, acetic acid to mix and add methylcellulose aqueous solution to form a slurry (viscosity is 10.2Pa s): copper acetate monohydrate 620g / L, acetic acid 130g / L, hydroxymethylcellulose 8g / L, antioxidant (ascorbic acid) 10g / L;

[0056] (2) Treat the surface of the glass substrate with sodium hydroxide and perform an ultrasonic heating treatment for 30 minutes;

[0057] (3) Spread the slurry evenly on the glass substrate (the thickness of the slurry is about 100 μm), and irradiate with laser to form a circuit (the laser spot diameter is 500nm-50μm, and the laser wavelength range is 193nm-1650nm);

[0058] (4) drying the glass substrate, and cleaning off excess slurry;

[0059] (5) Use tape to stick the line part and tear it off, and no powder is found.

Embodiment 2

[0061] Use titanium acetylacetonate and ethanol to make fine wire circuits to form a circuit with titanium as a flexible base material. The specific steps are as follows:

[0062] (1) Use titanium acetylacetonate and ethanol and isopropanol and water to mix to form a slurry (viscosity is 9.52Pa s): titanium acetylacetonate 260g / L, reducing agent ethanol and isopropanol are 50 and 60g / L respectively, viscosity Regulator (hydroxymethylcellulose) 10g / L, antioxidant (ascorbic acid) 15g / L;

[0063] (2) Use plasma to treat the PI flexible base material, and rinse with water;

[0064] (3) Spread the slurry evenly on the PI substrate (the thickness of the slurry is about 100 μm), and irradiate with laser to form a circuit;

[0065] (4) Remove excess slurry on the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com