A kind of forming device for straw coal processing

A forming device and straw coal technology, applied in the direction of material forming presses, manufacturing tools, stamping machines, etc., can solve the problems of poor forming effect and single forming specifications, and achieve convenient fixing, good forming effect, loading and unloading The effect of simple and convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

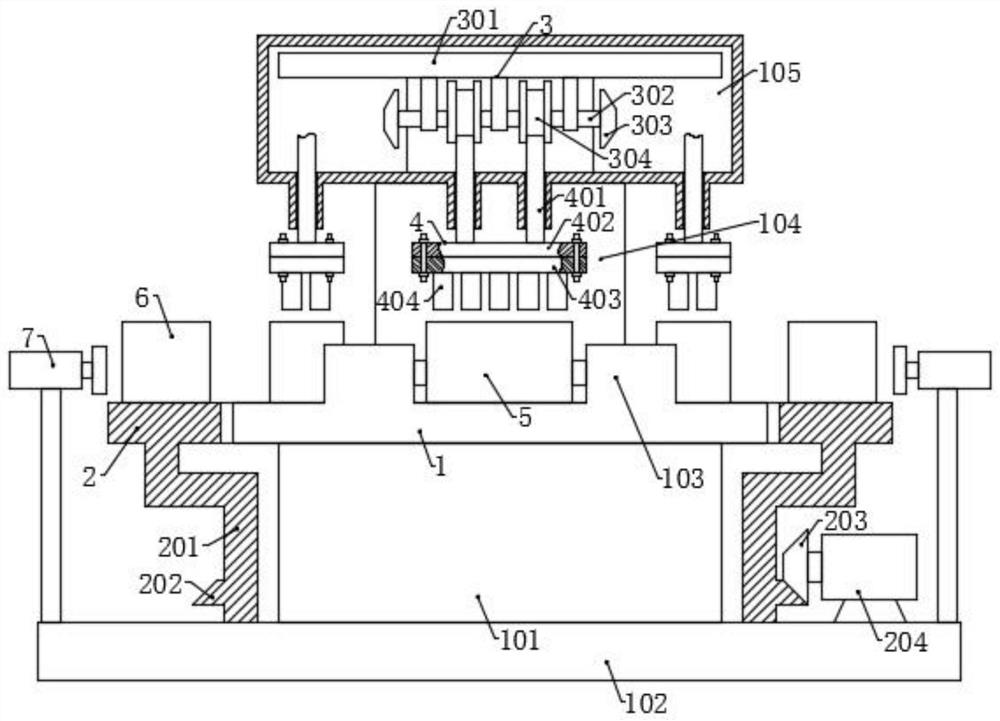

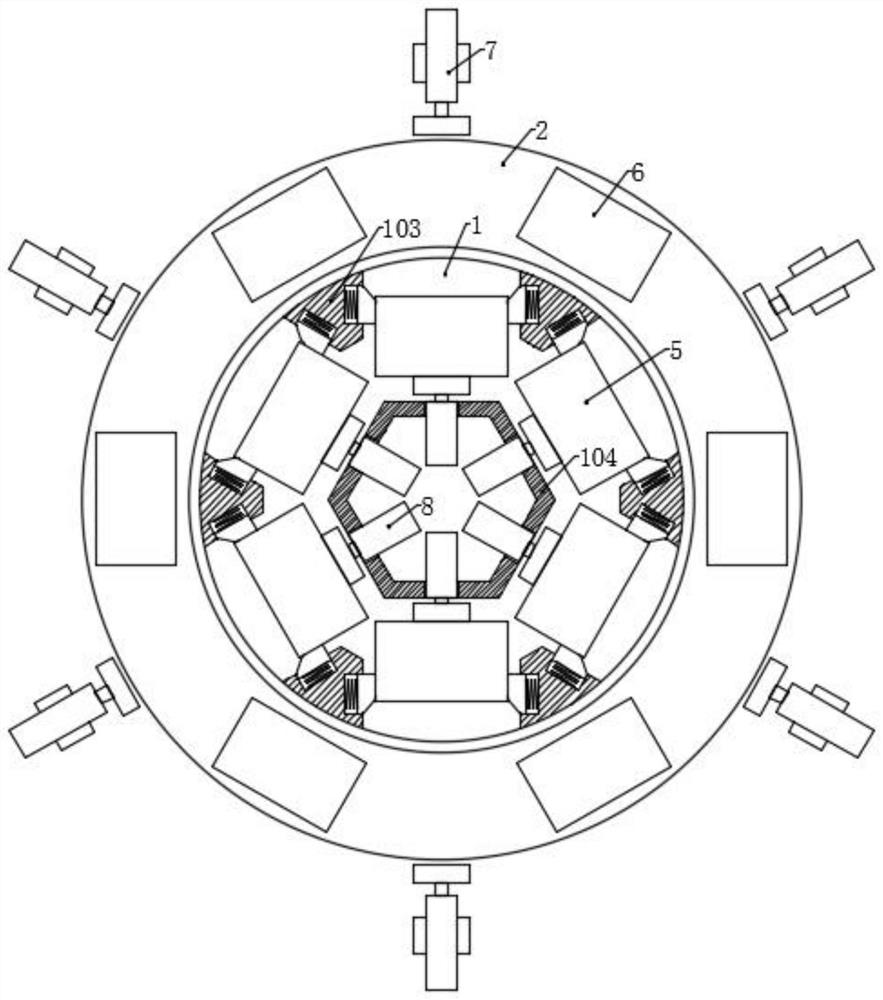

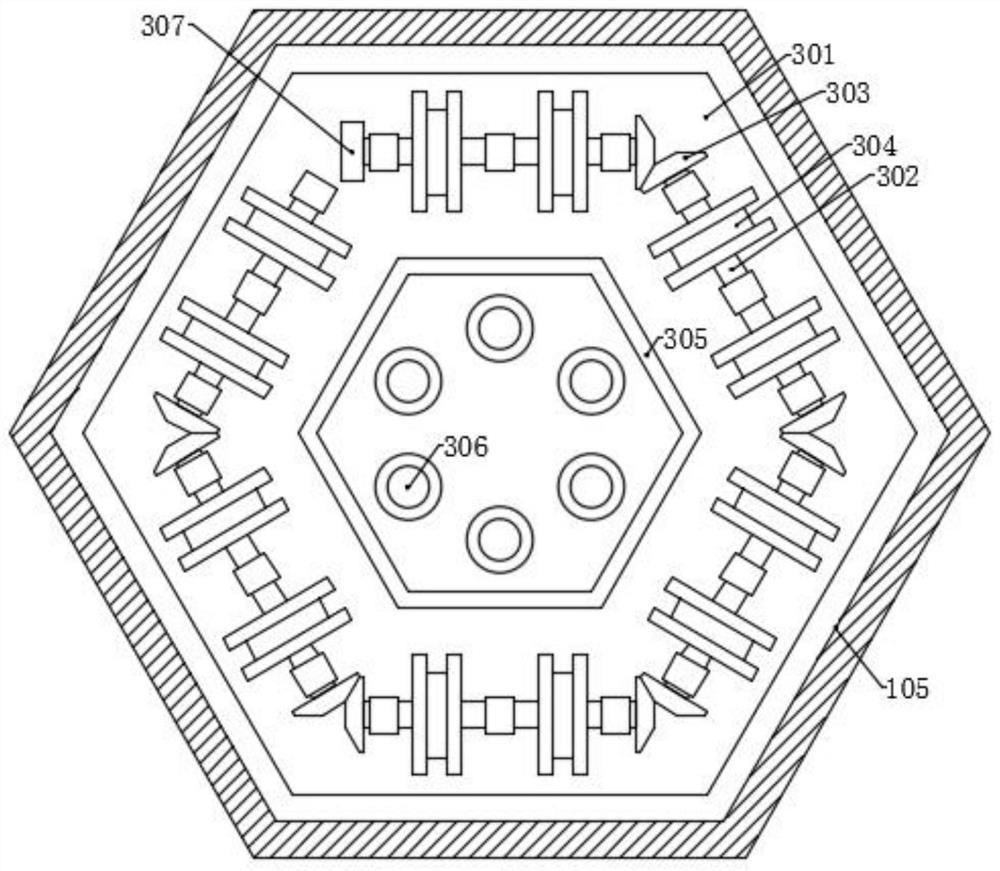

[0030] Please refer to the accompanying drawings, the present invention provides a technical solution: a forming device for straw coal processing, including a device main body, a turntable 2, a driving mechanism 3, a forming mechanism 4, a lifting mechanism 9, a first forming box 5 and a second Forming box 6, the main body of the device includes a fixed platform 1, the center of the bottom surface of the fixed platform 1 is fixedly connected with a support column 101, the bottom end of the support column 101 is fixedly connected with a support base 102, and the top surface of the fixed platform 1 The center is fixedly connected with a fixed column 104, and the top of the fixed column 104 is fixedly connected with a drive box 105. The bottom of the fixed column 104 is provided with a first installation groove, and the top is provided with a second installation groove, and the top of the second installation groove It communicates with the drive box 105. The rotating table 2 is an...

Embodiment 2

[0038] On the basis of Embodiment 1, the press table 402 is provided with a plurality of fixing holes, and bolts and nuts are arranged in the fixing holes, and a forming plate 403 is fixedly connected with the bolts and nuts, and the bottom surface of the forming plate 403 is evenly fixed with A plurality of forming briquetting blocks 404, the pressing table 402 can be disassembled and installed with different forming plates 403 and forming briquetting blocks 404 through bolts and nuts, combined with the first forming box 5 and the second forming box 6 processed with different forming grooves, it can produce Straw coal of different specifications.

Embodiment 3

[0040] On the basis of Embodiment 2, guide platforms 103 are fixed on the fixed platform 1 corresponding to both sides of the first forming box 5, and the inner surface of the guide platform 103 is provided with a spring groove, and a spring and a pressing block are arranged in the spring groove , the inside of the front end of the compression block is provided with a guide slope, and the inner surface of the compression block is connected with the two sides of the first forming box 5 correspondingly, and the first forming box 5 is limited by the guide table 103 and the compression block to avoid forming Move during the process, when the first forming box 5 is pushed onto the turntable 2, the turntable 2 turns 30°, the feeding push rod 7 pushes the second forming box 6, and the front end of the second forming box 6 is pressed against the guide slope The block squeezes out to both sides and continues to move forward, so that the compacting block is positioned at both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com