High-precision bearing producing and machining equipment of industrial robot

A technology for the production of industrial robots and bearings, which is applied to metal processing equipment, metal processing machinery parts, supports, etc., can solve the problems of increasing the loss of bearing rings and fixtures, affecting the cutting accuracy of bearing rings, etc., so as to improve stability and ensure cutting Accuracy, guaranteed occlusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

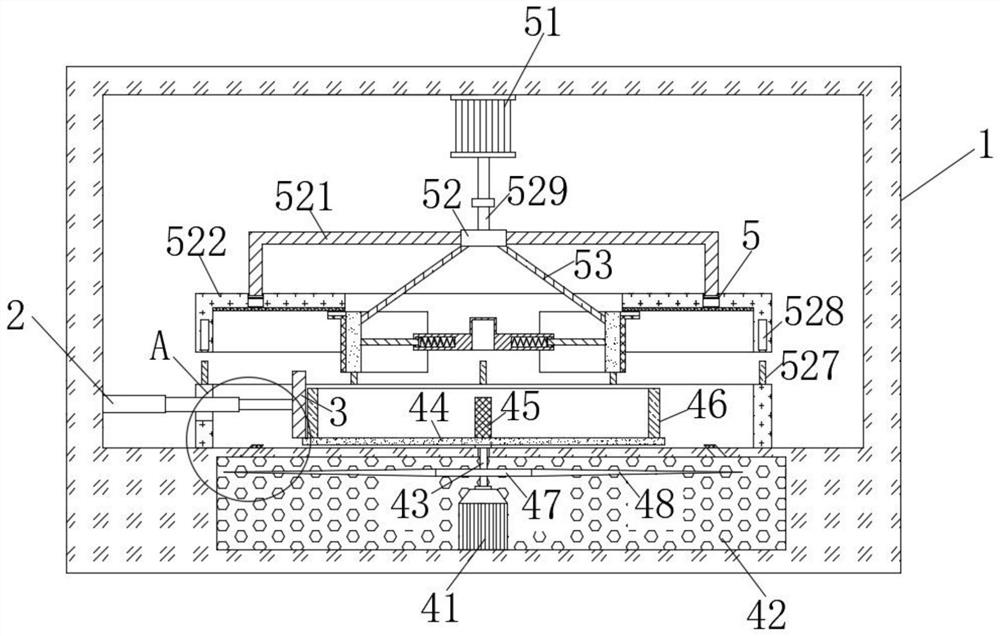

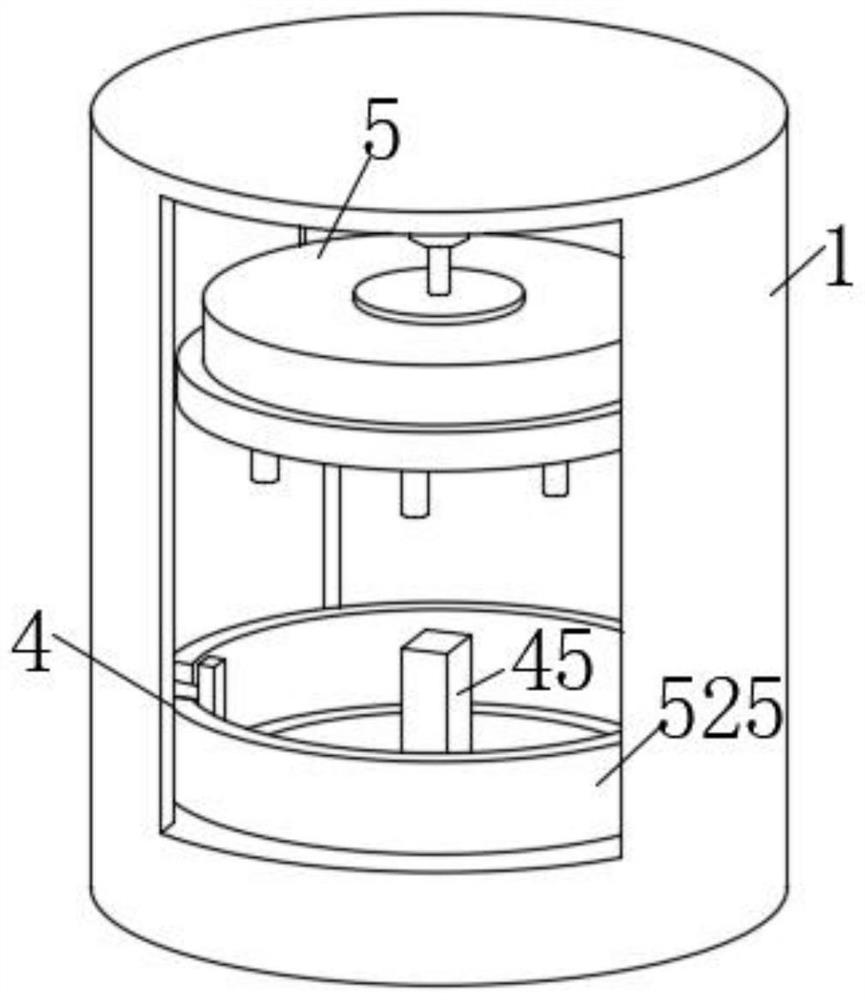

[0032] Such as Figure 1-7As shown, the high-precision bearing production and processing equipment of an industrial robot proposed by the present invention includes a base 1, an electric telescopic rod 2 and a cutting tool 3, and one side of the inner surface of the base 1 is provided with an electric telescopic rod 2, and the electric telescopic rod One end of 2 is provided with a cutting tool 3, the bottom end of the inner surface of the base 1 is provided with a rotating assembly 4, and the top of the inner surface of the base 1 is provided with a fixed assembly 5 at a position corresponding to the rotating part;

[0033] The rotating assembly 4 includes a motor 41, a movable chamber 42, a rotating rod 43, a rotating disk 44, a limit post 45 and a bearing ring 46. The bottom end of the inner surface of the base 1 is provided with a movable chamber 42, and the inside of the movable chamber 42 is provided with a motor 41 One end of the output shaft of the motor 41 is fixedly ...

Embodiment 2

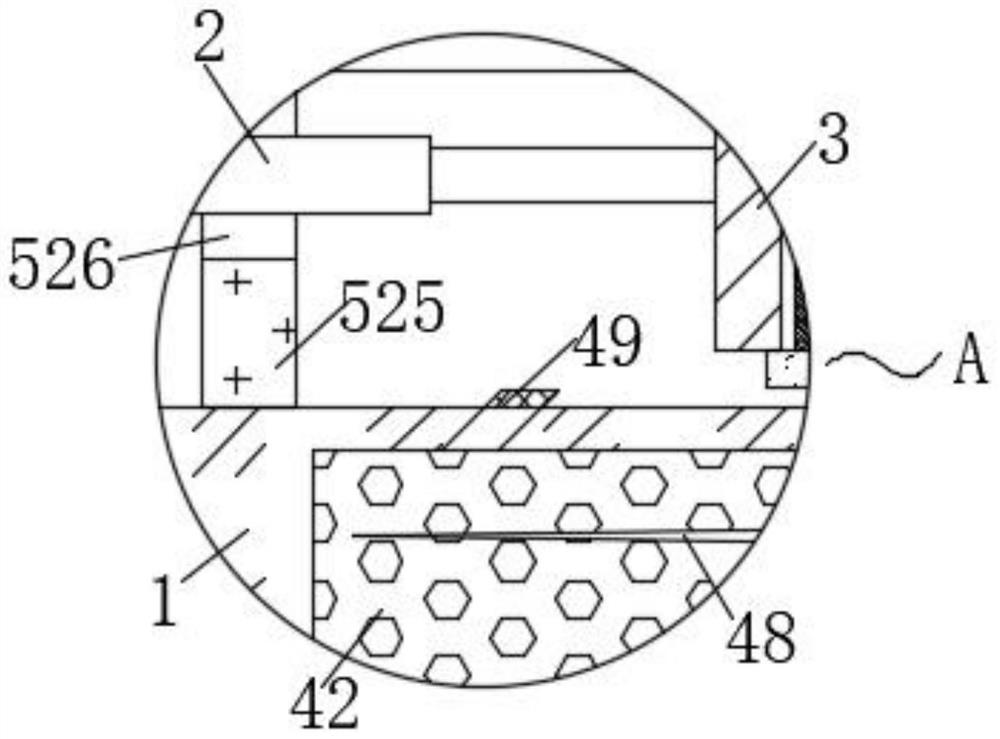

[0037] During the cutting process, the bearing ring 46 and the cutting tool 3 produce high-speed friction, so a large amount of heat will be generated, which will affect the loading and unloading of the bearing ring 46 by the operator. There is a connecting ring 47, and the outer surface of the connecting ring 47 is fixedly connected with several groups of fan blades 48 at equal annular distances. The bottom end of the inner surface of the base 1 is located around the turntable 44. There are several groups of air outlet nozzles 49, and the air outlet nozzles 49 The inside of the movable chamber 42 communicates with the inside of the movable chamber 42, and the two sides of the inner surface of the movable chamber 42 are hollowed out to facilitate the circulation of gas. , the connecting ring 47 drives the fan blade 48 on its surface to rotate, thereby pushing the airflow below the fan blade 48 to its upper side, and making it spray to the surroundings of the bearing ring 46 thr...

Embodiment 3

[0039] A certain amount of iron filings will be produced during the cutting process. Since the bearing is usually in a high-speed running state during the cutting process, the iron filings are easy to splash around, which is not only difficult to clean, but also easy to damage the surface of the equipment when the iron filings are splashed. cause damage, even accidental injury to the operator, and increase the danger in the processing process. The outer surface of the fixed block 52 is fixedly connected with the limit frame 521, and the first shield frame 522 is arranged below the limit frame 521. The first shield The outer surface of the upper end of the frame 522 is provided with an annular groove 523, and the interior of the annular groove 523 is provided with an annular plate 524. The limit frame 521 penetrates into the interior of the annular groove 523 and is fixedly connected with the annular plate 524. The limit frame 521 is connected to the first The shielding frame 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com