Large package unloading device for logistics

A large-scale, parcel technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve the problems of large-scale parcels being easily damaged in contact with transport vehicles, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

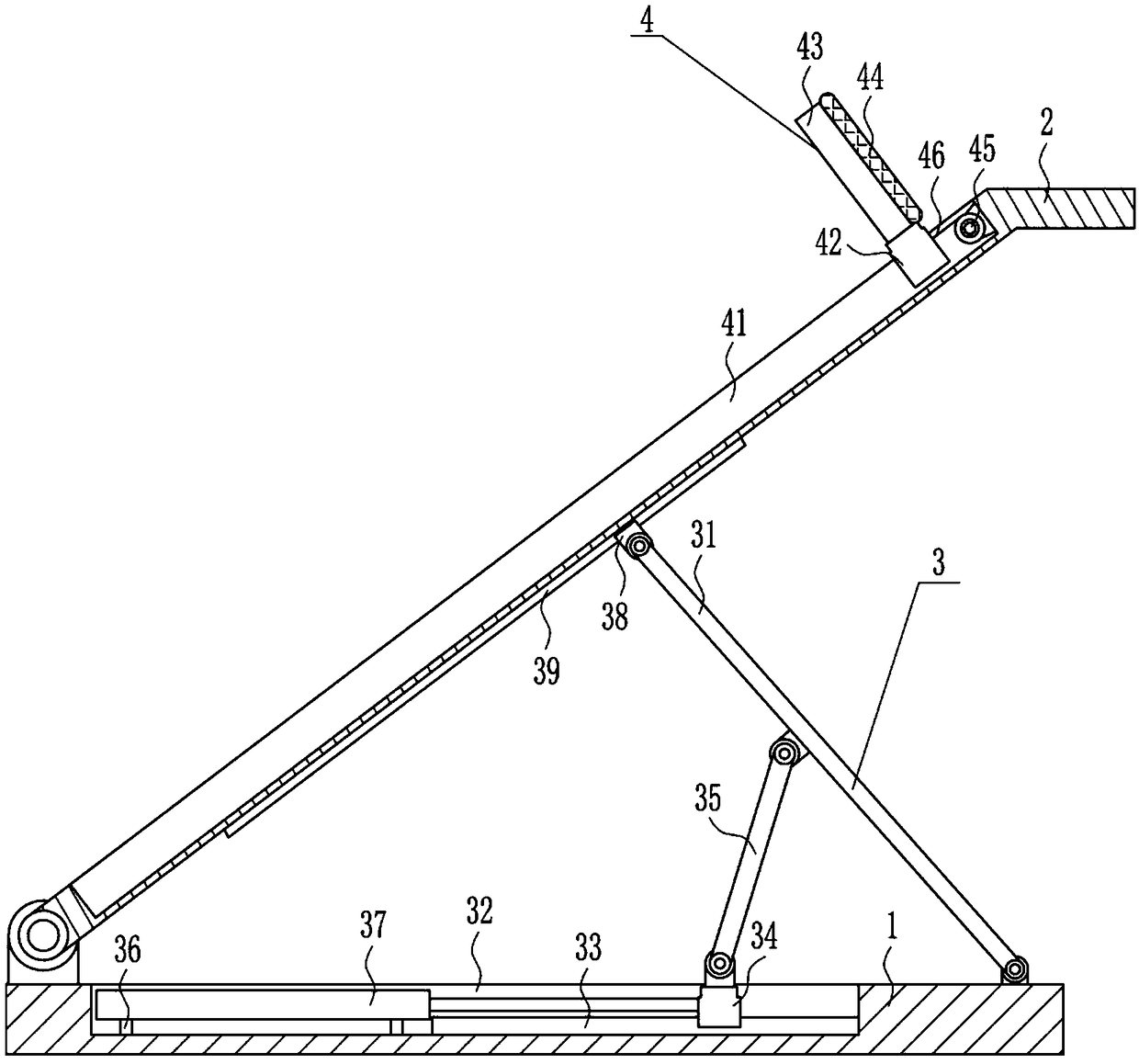

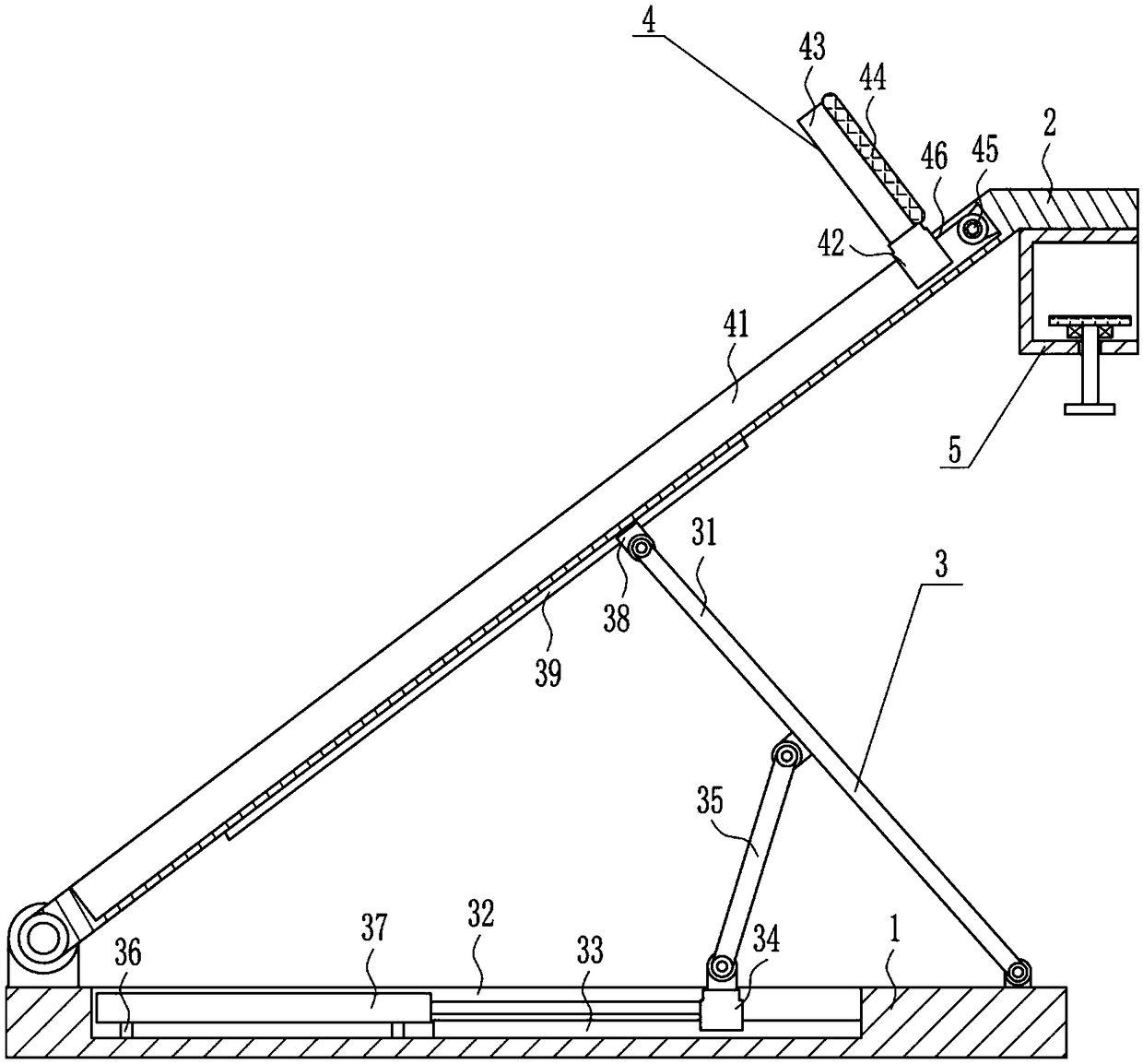

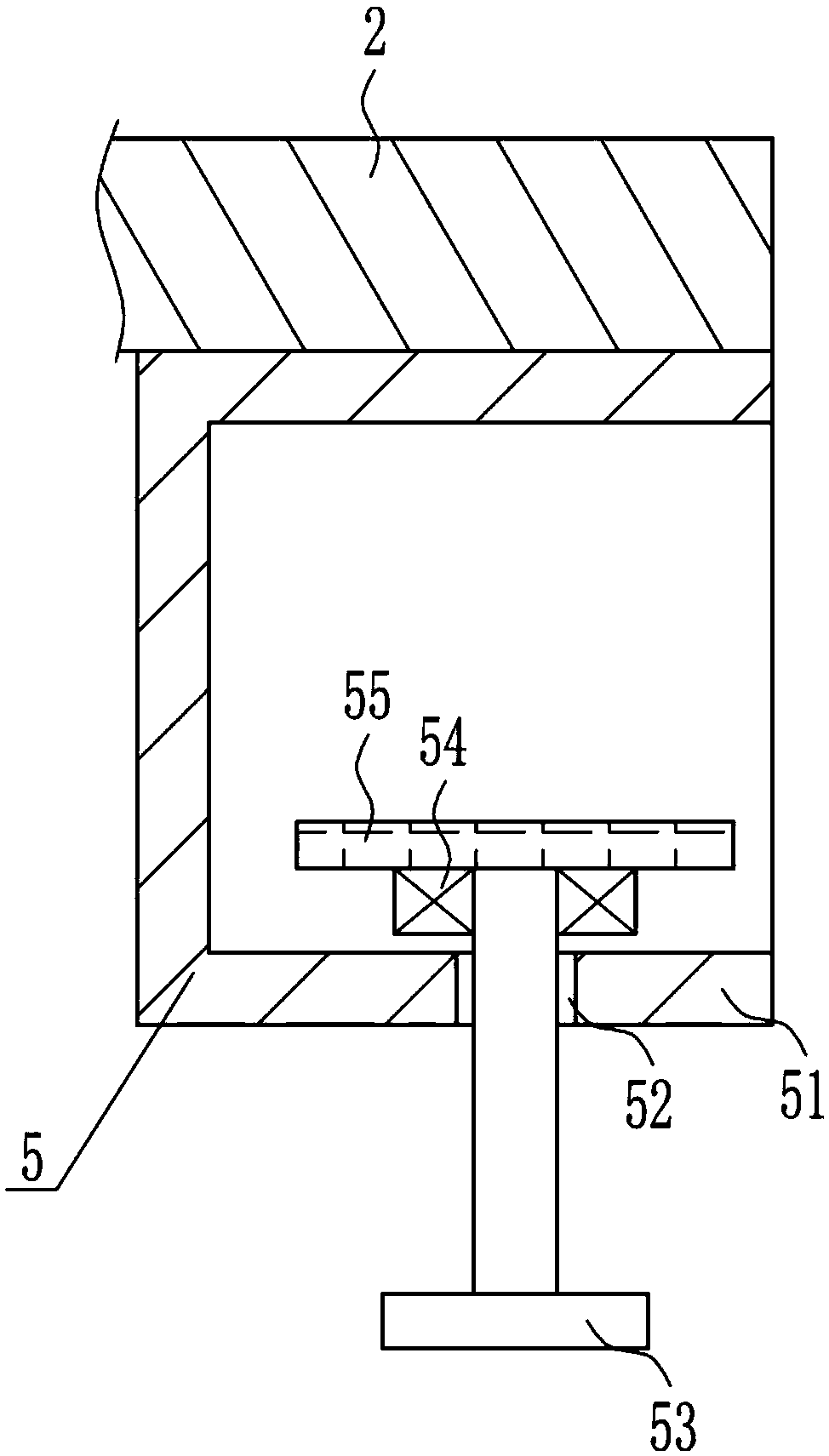

[0028] A large parcel unloading device for logistics, such as Figure 1-6 As shown, it includes a base plate 1, a movable plate 2, a lifting device 3 and a conveying device 4. The left side of the bottom plate 1 is connected with a movable plate 2 through a hinged connection, and a lifting device 3 is arranged above the base plate 1. There is a conveying device 4 .

Embodiment 2

[0030] A large parcel unloading device for logistics, such as Figure 1-6 As shown, it includes a base plate 1, a movable plate 2, a lifting device 3 and a conveying device 4. The left side of the bottom plate 1 is connected with a movable plate 2 through a hinged connection, and a lifting device 3 is arranged above the base plate 1. There is a conveying device 4 .

[0031]The lifting device 3 includes a first connecting rod 31, a first slide rail 33, a first slide block 34, a second connecting rod 35, a pole 36, a cylinder 37, a third slide block 38 and a third slide rail 39, and the bottom plate 1 The right side of the top is connected with the first connecting rod 31 by means of hinged connection, the third slide rail 39 is installed at the bottom of the movable plate 2, the third slide rail 39 is slidably provided with the third slide block 38, and the top of the first connecting rod 31 It is connected with the bottom of the third slide block 38 by means of a hinged conne...

Embodiment 3

[0033] A large parcel unloading device for logistics, such as Figure 1-6 As shown, it includes a base plate 1, a movable plate 2, a lifting device 3 and a conveying device 4. The left side of the bottom plate 1 is connected with a movable plate 2 through a hinged connection, and a lifting device 3 is arranged above the base plate 1. There is a conveying device 4 .

[0034] The lifting device 3 includes a first connecting rod 31, a first slide rail 33, a first slide block 34, a second connecting rod 35, a pole 36, a cylinder 37, a third slide block 38 and a third slide rail 39, and the bottom plate 1 The right side of the top is connected with the first connecting rod 31 by means of hinged connection, the third slide rail 39 is installed at the bottom of the movable plate 2, the third slide rail 39 is slidably provided with the third slide block 38, and the top of the first connecting rod 31 It is connected with the bottom of the third slide block 38 by means of a hinged conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com