Jacking device and method for replacing steel ladle rotating disc bearing

A technology of slewing bearing and jacking device, which is applied in the direction of lifting device, fluid pressure actuating device, mechanical equipment, etc., can solve the problems of difficulty in correcting deviation, difficult to achieve synchronous jacking, equipment deviation, etc., so as to reduce labor intensity , to promote the use value and improve the effect of construction work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

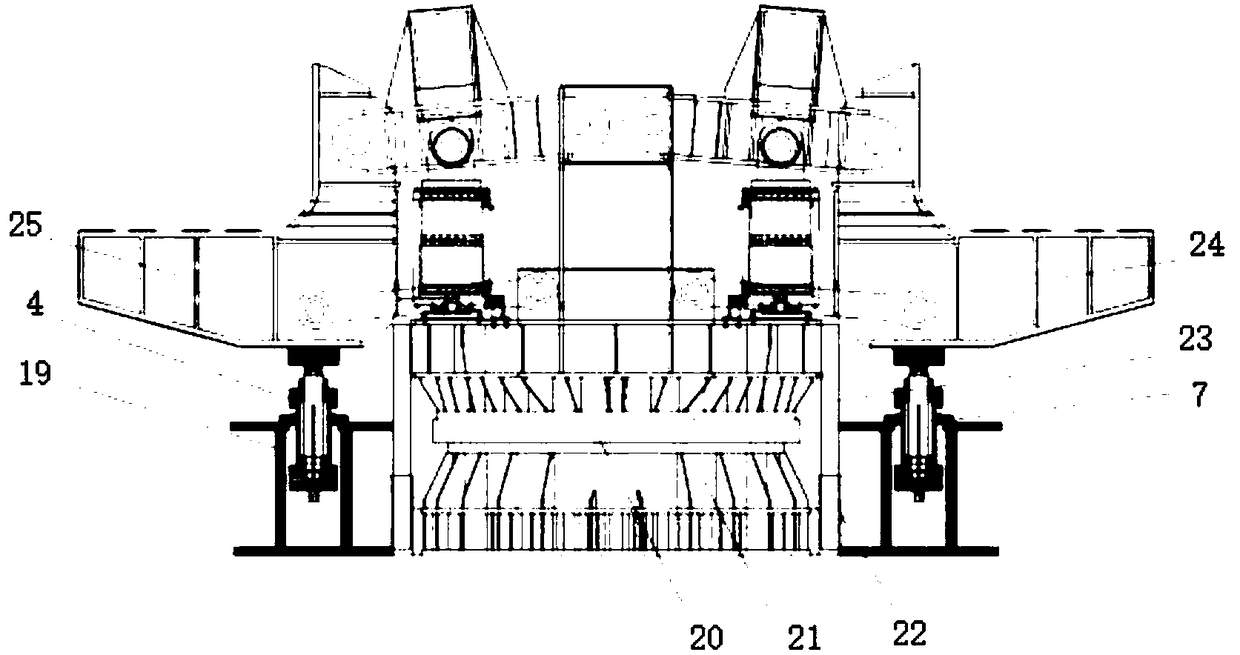

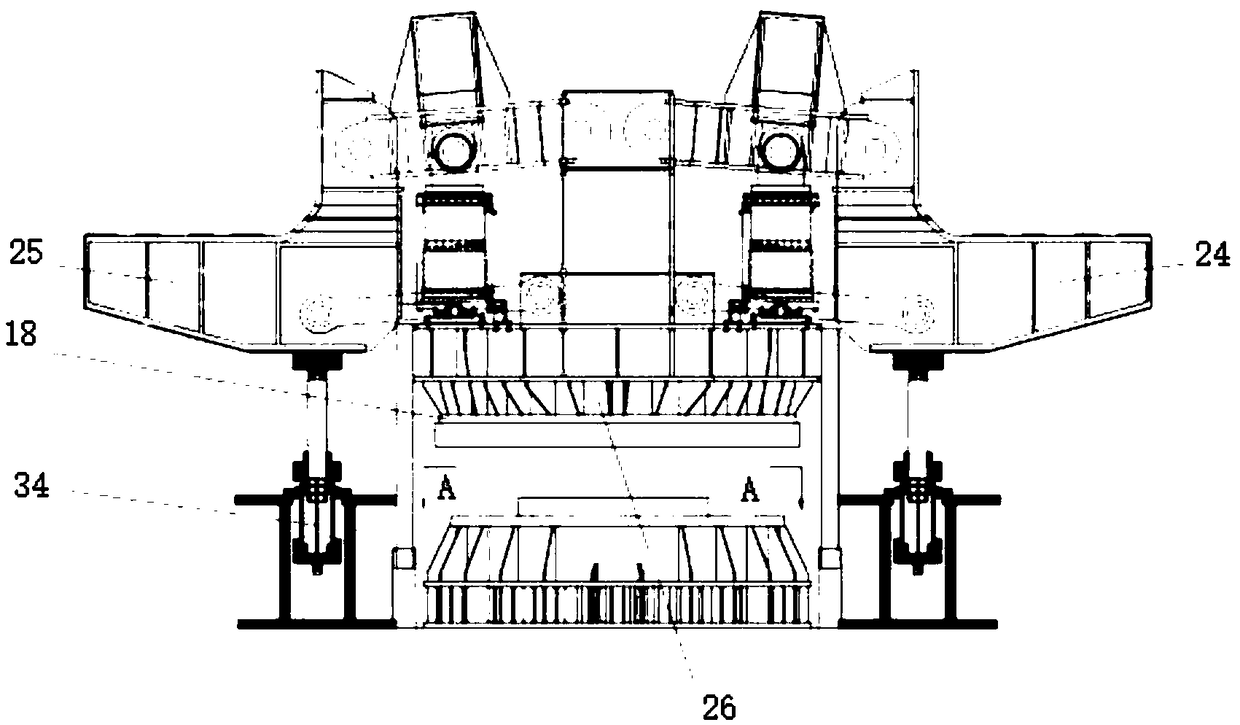

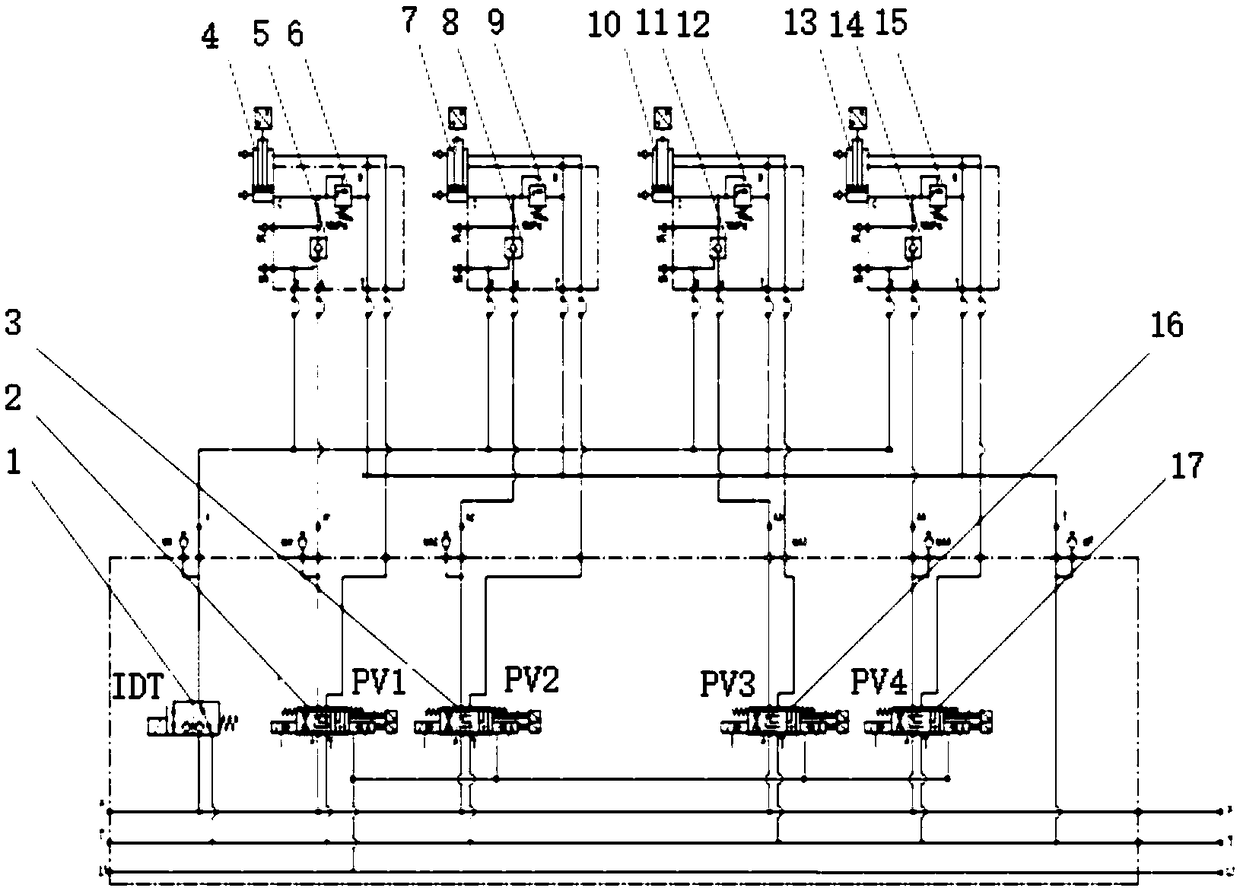

[0034] The jacking device for replacing the ladle turntable bearing of the present invention is composed of a jacking hydraulic part, a sliding support 28 and a positioning device.

[0035] The jacking hydraulic part is composed of an electromagnetic cut-off valve 1 and four groups of the same jacking hydraulic devices, and each group of jacking hydraulic devices includes a proportional valve, a jacking hydraulic cylinder, a hydraulic control check valve, and an overflow valve; the sliding bracket 28 consists of Sliding support frame 33, sliding support front leg 27, one leg 29 after the sliding support, two legs 30 after the sliding support, three legs 31 after the sliding support form;

[0036] figure 1 , 2It shows that the jacking bases 19 of the four jacking hydraulic cylinders of the four sets of jacking hydraulic devices are respectively placed under the first lifting arm 25 and the second lifting arm 24, and the ejector rods of the four jacking hydraulic cylinders are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com