A weather-resistant matte polycarbonate regenerated material and its preparation method

A technology of polycarbonate and weather resistance, which is applied in the field of weather-resistant matte polycarbonate recycled materials and its preparation, can solve the problems of burden and inability to recycle polycarbonate waste materials, and achieve burden reduction, high mechanical strength, and weather resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

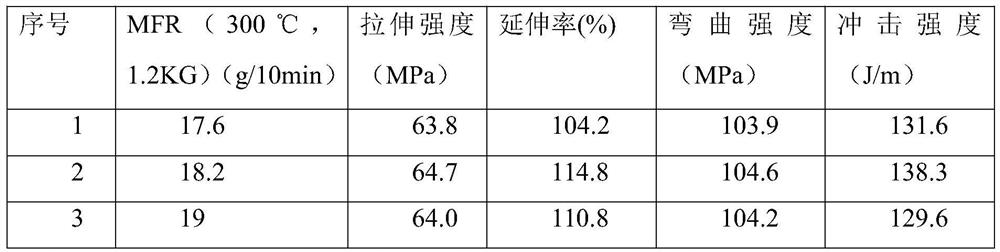

Examples

Embodiment 1

[0025] The weather-resistant matte polycarbonate recycled material is composed of the following raw materials in parts by mass:

[0026] The first polycarbonate recycled crushed material: 8

[0027] The second polycarbonate recycled crushed material: 73

[0028] The third polycarbonate recycled crushed material: 3

[0029] Fog agent: 14.7

[0030] Antioxidant: 0.5

[0031] Light stabilizer: 0.3

[0032] UV absorber: 0.5

[0033] The first polycarbonate recycled pulverized material is water bottle recycled material. According to ASTM D1238 at 300°C and 1.2KG, the melt mass flow rate (MFR) tested is 3-4g / 10min, and the diameter is 2-4mm.

[0034] The second polycarbonate recycled crushed material is PC recycled material with film. The crushed material obtained after crushing, cleaning, washing, drying, coarse crushing, fine crushing and other processes, according to ASTM D1238 at 300 ° C, 1.2KG conditions, The tested MFR is 14-16g / 10min and the diameter is 2-4mm.

[0035]...

Embodiment 2

[0042] The weather-resistant matte polycarbonate recycled material is composed of the following raw materials in parts by mass:

[0043] The first polycarbonate recycled crushed material: 3

[0044] Second polycarbonate recycled crushed material: 60

[0045] The third polycarbonate recycled crushed material: 6

[0046] Fog agent: 10

[0047] Antioxidant: 0.2

[0048] UV absorber: 0.1

[0049] The first polycarbonate recycled crushed material is water bottle recycled material. After crushing, washing, drying, coarse crushing, and fine crushing, the crushed material is obtained. According to ASTMD1238 at 300°C and 1.2KG, the MFR of the test is 5-6g / 10min , 2-4mm in diameter.

[0050] The second polycarbonate recycled pulverized material is the reclaimed car lamp rubber head, which is coarsely pulverized and finely pulverized to obtain a pulverized material with a diameter of 2-4mm. According to ASTM D1238 at 300°C and 1.2KG, the tested MFR is: 12-13g / 10min.

[0051] The t...

Embodiment 3

[0058] The weather-resistant matte polycarbonate recycled material is composed of the following raw materials in parts by mass:

[0059] The first polycarbonate recycled crushed material: 15

[0060] The second polycarbonate recycled crushed material: 83

[0061] The third polycarbonate recycled pulverized material: 10

[0062] Fog agent: 25

[0063] Antioxidant: 1

[0064] Light stabilizer: 0.6

[0065] UV absorber: 1

[0066] The first polycarbonate recycled crushed material is water bottle recycled material. After crushing, washing, drying, coarse crushing, and fine crushing, the crushed material is obtained. Under the conditions of 300°C and 1.2KG, the MFR is 2-3g / 10min.

[0067] The second polycarbonate recycled crushed material is the recycled car lamp rubber head, which is coarsely crushed and finely crushed to obtain a crushed material with a diameter of about 2-4mm. Under the conditions of 300°C and 1.2KG, the MFR is 17- 18g / 10min.

[0068] The third polycarbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com