A low-cost, high-strength, hot-corrosion-resistant nickel-based superalloy and its preparation process and application

A nickel-based superalloy and a preparation process technology, applied in the field of nickel-based superalloys, can solve the problem that the temperature bearing capacity is difficult to meet the design requirements of G/H-class heavy-duty gas turbines, so as to ensure the stability of the structure, ensure the thermal corrosion resistance, and improve the The effect of high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

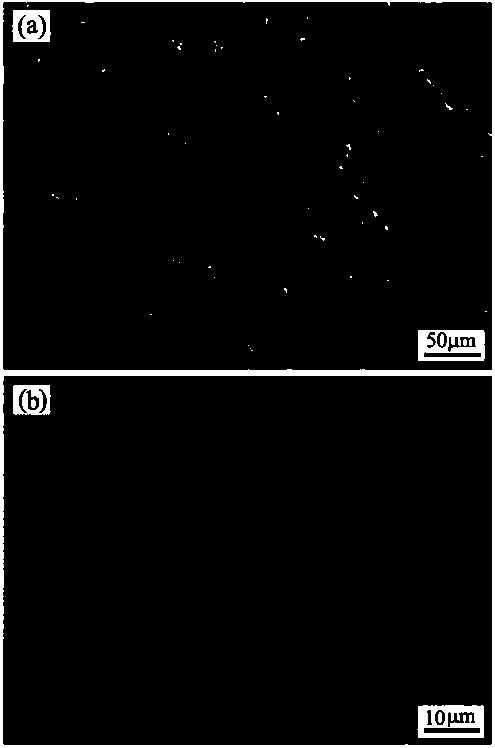

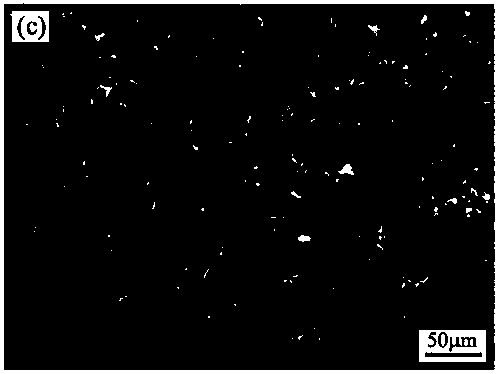

[0046] The 850 ℃ long-term structural stability of embodiment alloy (No.6 and No.2), as figure 2 shown. No.6 Alloy (N v =2.53) After aging for 1000h, a small amount of σ phase was precipitated (see figure 2 (a)); No.2 alloy (N v =2.45) After aging for 1000h, no TCP phase was precipitated (see figure 2 (b)). It can be seen that in order to ensure the structural stability of the alloy, it is necessary to limit the N of the alloy of the present invention. v The value is less than 2.45.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com