Embossing cloth as well as production technology and production equipment thereof

A technology of production process and production equipment, which is applied in the decoration of textiles, textiles and papermaking, warp knitting, etc., and can solve the problem of poor touch feeling, unsatisfactory embossing effect of polyester fabrics, and shallow lines on the surface of polyester embossed fabrics. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

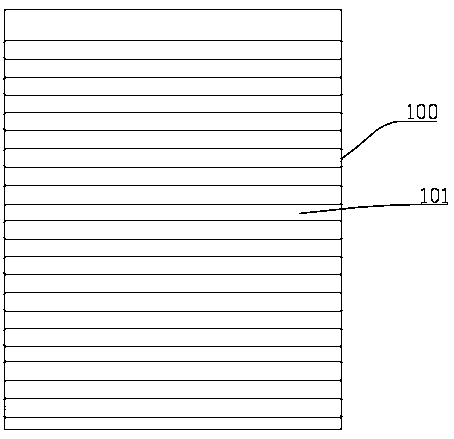

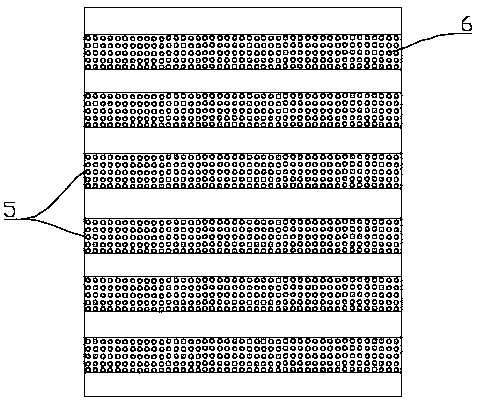

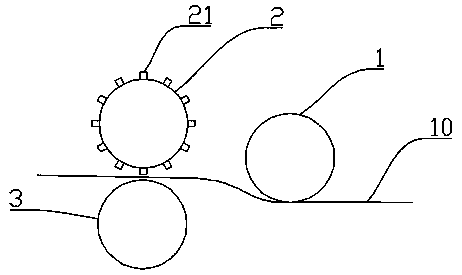

[0038] Such as image 3 , first, add alkali-resistant and reduction paste PE powder together with distilled water into the reactor, the temperature of the reactor is controlled at 30-35°C, the stirring time is 2-3h, and the original paste with a solid content of 8% is made; then Heat the reaction kettle to 35°C, add sodium hydroxide solution, urea solution, sodium methylene bis-naphthalene sulfonate, polyoxyethylene fatty acid ester and distilled water in sequence, and stir for 2 hours to make burnt-out pulp; then warp knitting The polyester cloth is washed with clean water and dried, and the high-temperature resistant release film is combined with the surface of the cloth body and the cloth body is completely covered to form a composite cloth. 1 enters between the burn-in roller 2 and the pressure roller 3, the burn-in roller 2 is arranged on the upper side of the pressure roller 3, and the surface of the burn-in roller 2 is evenly provided with a plurality of strip-shaped pr...

Embodiment 2

[0041] First, put the alkali-resistant and reduction-resistant paste PE powder into the reaction kettle together with distilled water. The temperature of the reaction kettle is controlled at 30-35°C, and the stirring time is 2-3h to make the original paste with a solid content of 8%. The reaction kettle was heated up to 35°C, sodium hydroxide solution, urea solution, sodium methylene bis-naphthalene sulfonate, fatty acid polyoxyethylene ester and distilled water were added in sequence, and the stirring time was 2 hours to make burnt-out pulp; then warp-knitted polyester After the cloth is washed with clean water and dried, the high-temperature-resistant release film is compounded with the surface of the cloth body and the cloth body is completely covered to form a composite cloth. Enter between the burn-in roller 2 and the pressure roller 3, the burn-in roller 2 is arranged on the upper side of the pressure roller 3, and the surface of the burn-out roller 2 is evenly provided w...

Embodiment 3

[0044] First, put the alkali-resistant and reduction-resistant paste PE powder into the reaction kettle together with distilled water. The temperature of the reaction kettle is controlled at 30-35°C, and the stirring time is 2-3h to make the original paste with a solid content of 8%. The reaction kettle was heated up to 35°C, sodium hydroxide solution, urea solution, sodium methylene bis-naphthalene sulfonate, fatty acid polyoxyethylene ester and distilled water were added in sequence, and the stirring time was 2 hours to make burnt-out pulp; then warp-knitted polyester After the cloth is washed with clean water and dried, the high-temperature-resistant release film is compounded with the surface of the cloth body and the cloth body is completely covered to form a composite cloth. Enter between the burn-in roller 2 and the pressure roller 3, the burn-in roller 2 is arranged on the upper side of the pressure roller 3, and the surface of the burn-out roller 2 is evenly provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com