Steel bridge deck pavement structure

A steel bridge deck and pavement technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of increasing the constant weight of steel bridge decks, the difficulty of concrete, and the insufficient shear resistance of concrete, and can repair fracture cracks and fatigue. Damage, strong absorption and transmission of various stresses, and the effect of solving shear resistance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

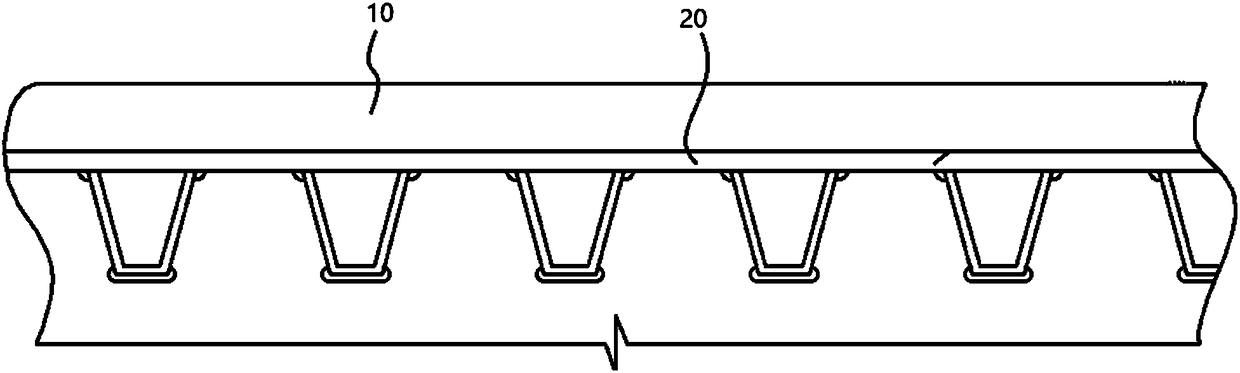

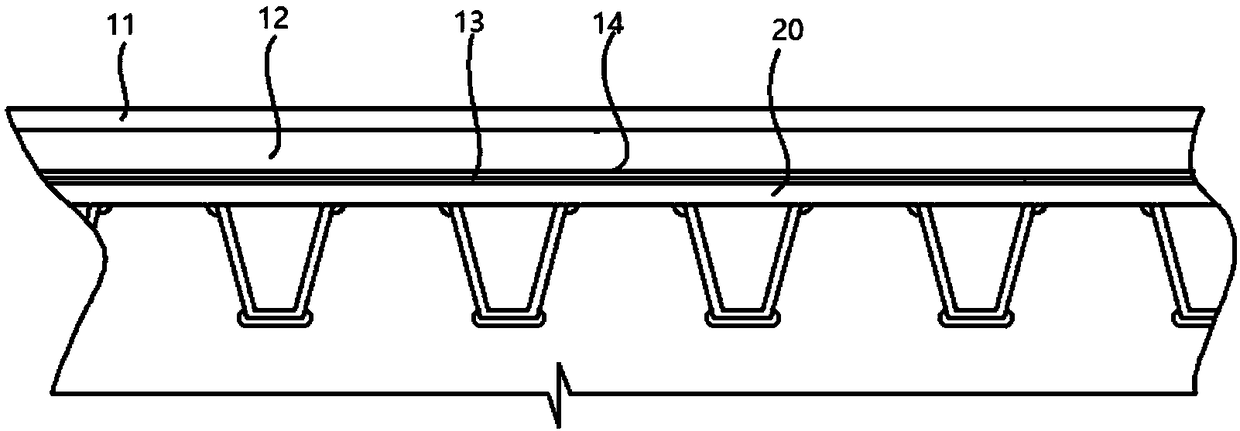

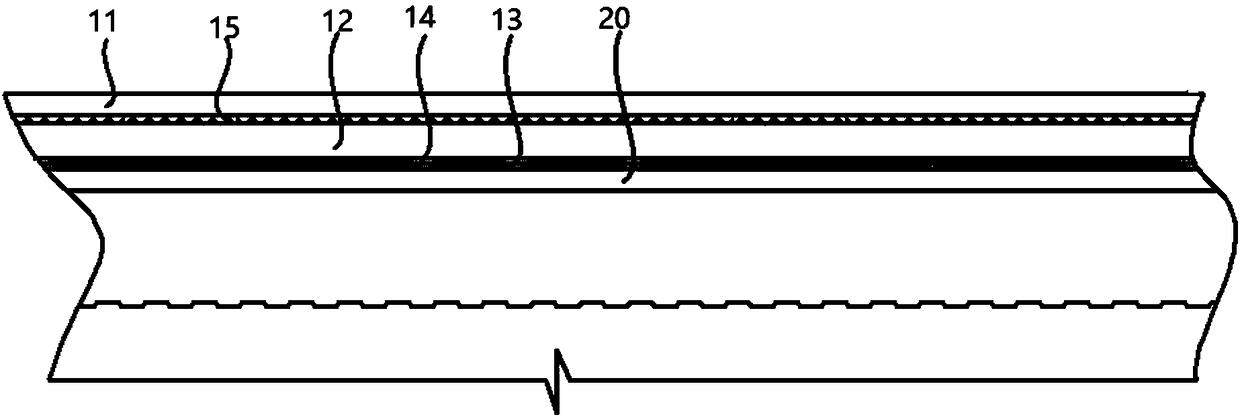

[0018] Such as figure 1 , 2 As shown, an embodiment of the present invention discloses a steel bridge deck pavement structure, including laying a composite structure 10 on a steel bridge deck 20, and the composite structure 10 includes an interface layer 13 that is laid sequentially from bottom to top and bonded to each other , Polyurethane-based fiber-reinforced material board 12 and wearing layer 11.

[0019] The interface layer 13 is formed by bonding and curing polyurethane resin and fiber material on the steel bridge deck 20 . The function of the interface layer 13 is to seal the steel bridge deck and isolate it from moisture; at the same time, it forms a layer of dense polar polymer surface so that it can be tightly bonded to the polyurethane-based fiber reinforced material plate 12; in addition, it becomes a shear stress The transfer layer enables the internal shear stress of the entire steel bridge deck 20 and the composite structure 10 to be evenly distributed in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com