an oil inlet valve

An oil inlet valve and oil inlet technology, applied in the field of hydraulic valves, can solve problems such as troublesome shunt structure, and achieve the effect of stable pressure and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

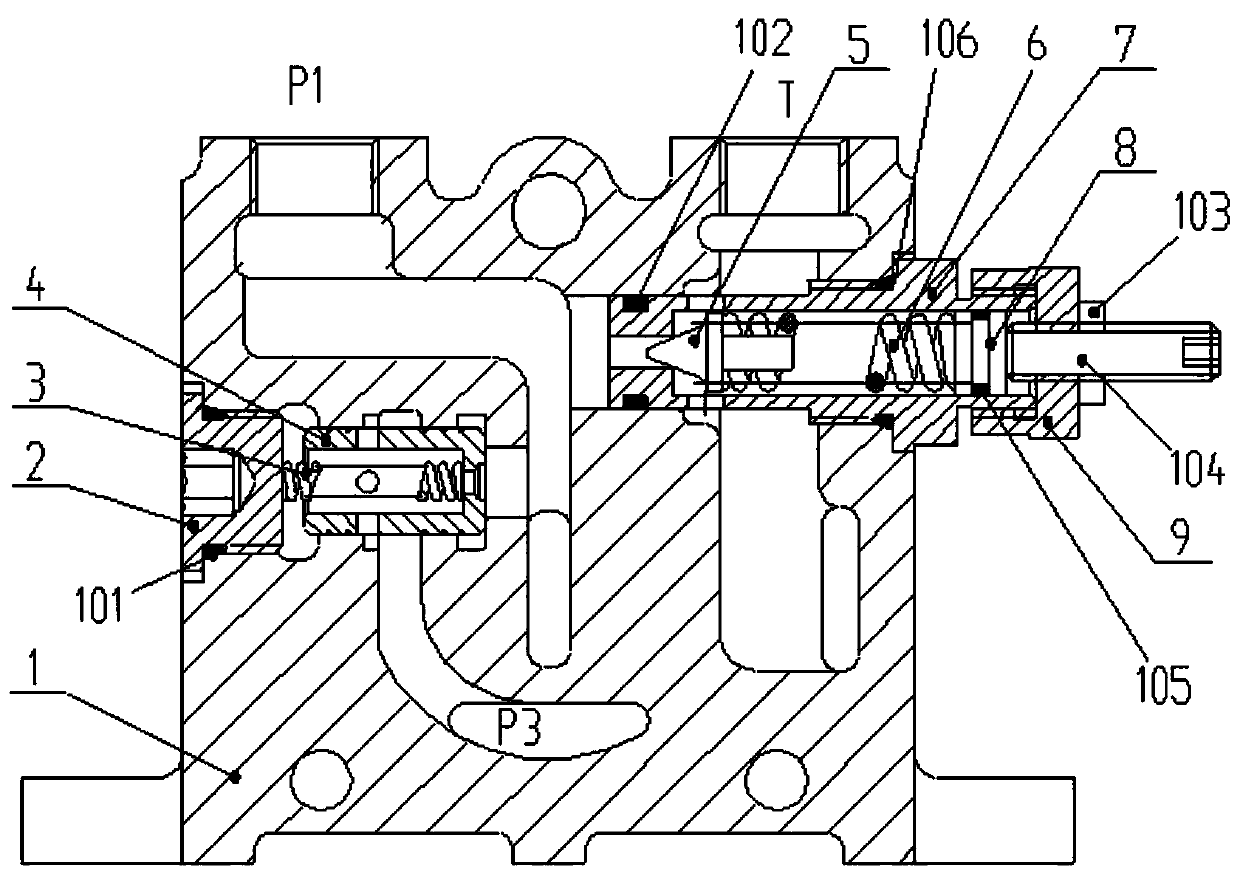

[0035] An embodiment, a working method of an oil inlet valve plate, comprising the following steps:

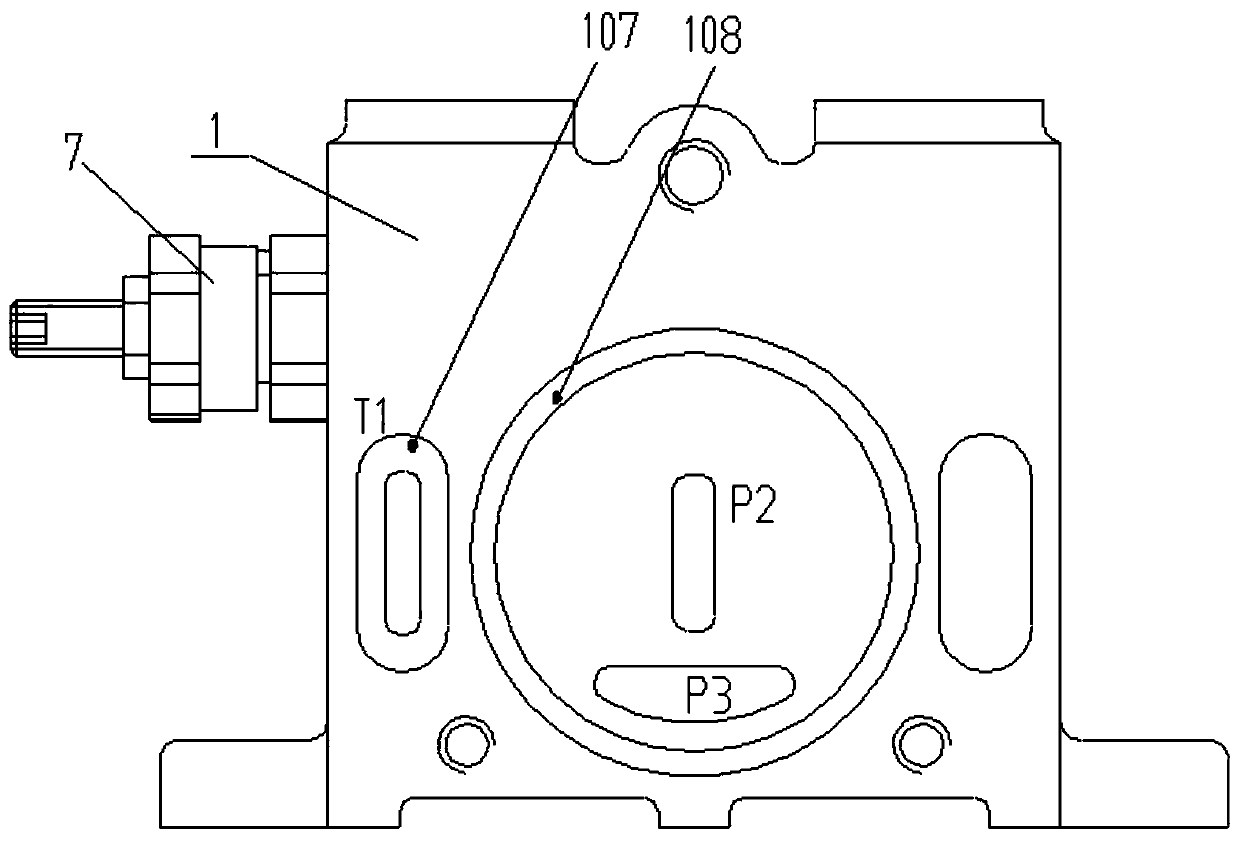

[0036] Step 1: After connecting the device with the outside, connect the oil pump to the oil inlet P1, and the oil inlet P1 is diverted to the oil inlet P2 through the oil passage inside the valve body 1, and the other way is diverted to the oil inlet P2 through the diverter valve core 4. Oil inlet P3;

[0037] Step 2: When the pressure oil in the oil inlet P1 is greater than the elastic force of the spring 6, the pressure oil overcomes the elastic force of the spring 6 and pushes the valve needle 5 to the right, and the pressure oil flows into the oil return port T through the oil hole 701;

[0038] Step 3: After the pressure oil and the oil return port T are connected, the pressure drops, the spring force of the spring 6 is greater than the force of the pressure oil acting on the valve needle 5, and the spring 6 resets to push the valve needle 5 to the left, closing the oil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com