Radial equilibrium small-tooth-difference speed reducer for carrier driving wheel

A technology of radial balance and drive wheel, which is applied in the direction of transmission, transmission parts, gear transmission, etc., and can solve the problems of high load strength, complex structure and short service life of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

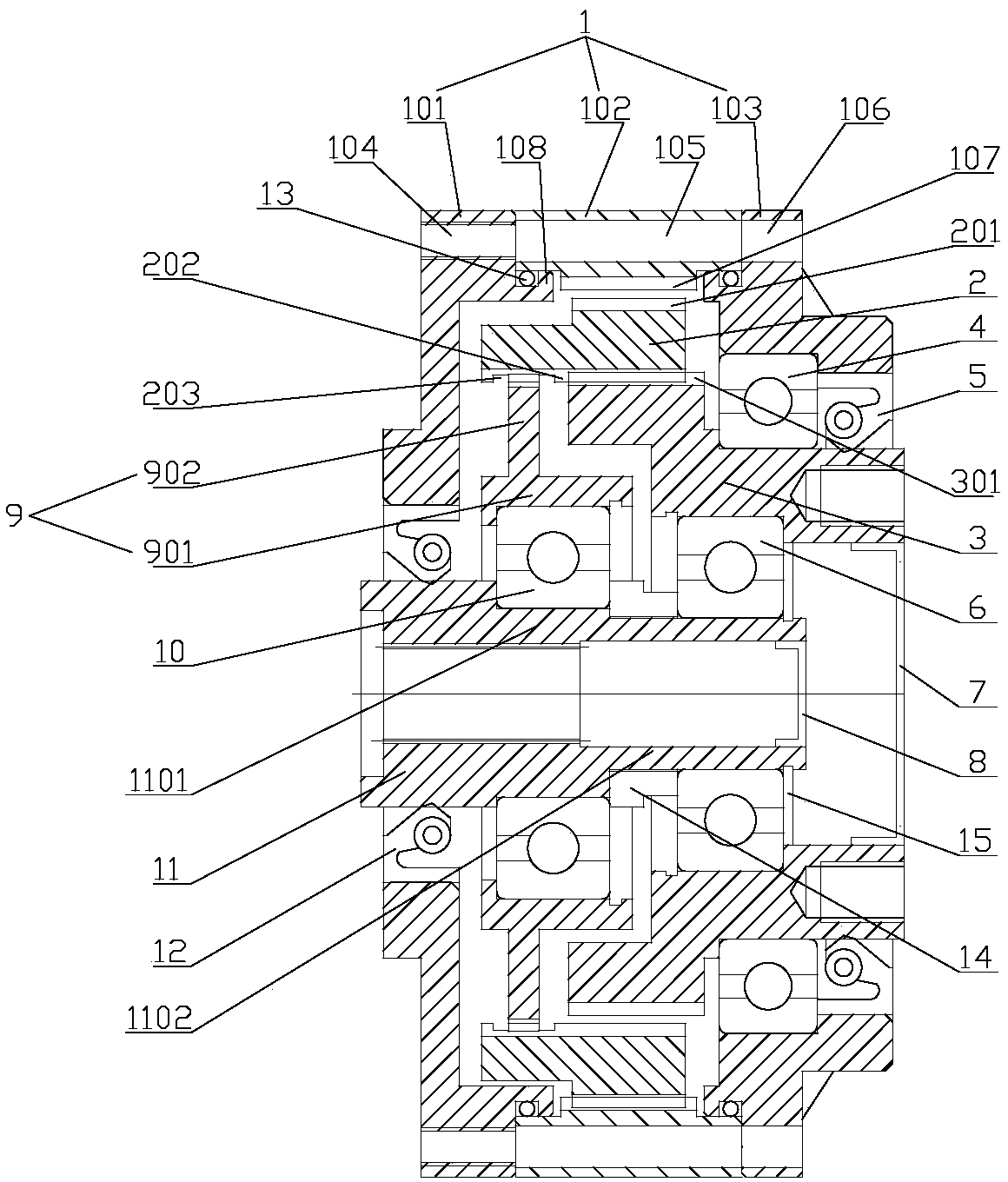

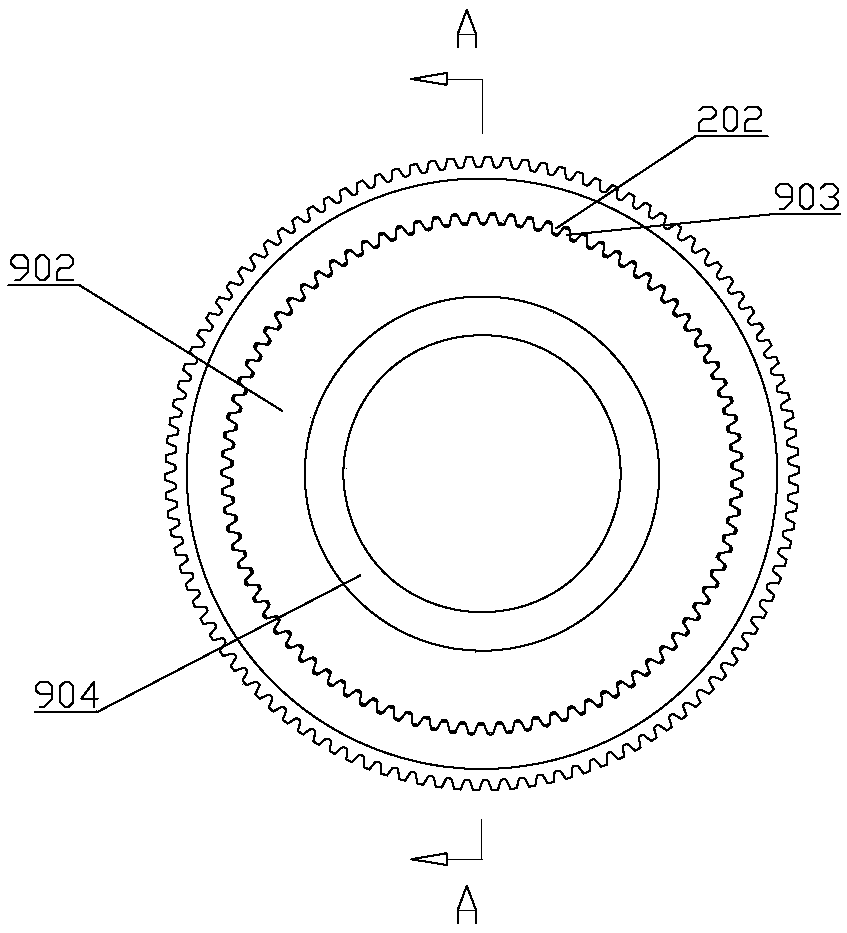

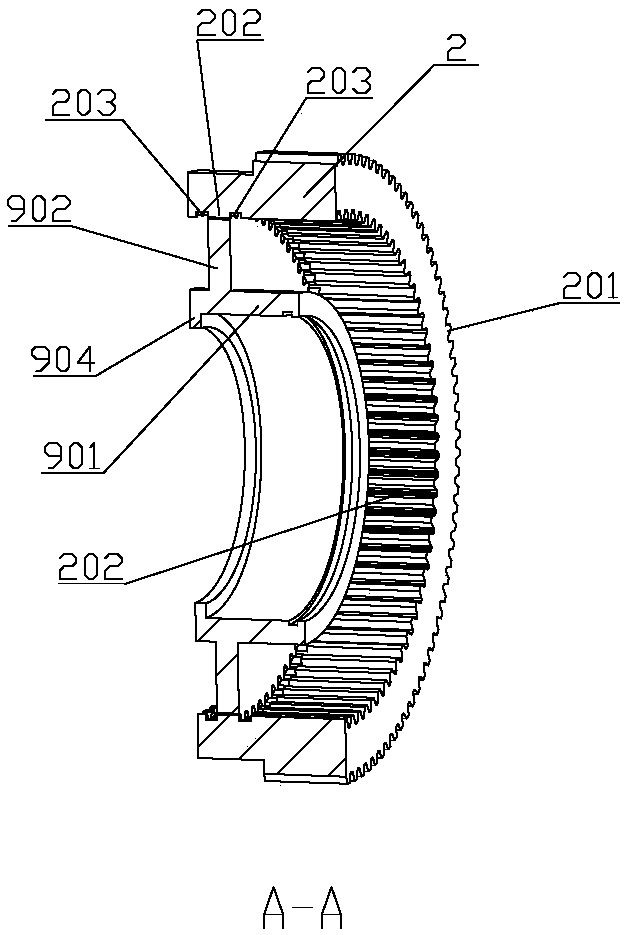

[0021] like figure 1 As shown, a radially balanced reducer with less tooth difference for the driving wheel of a truck includes a housing 1, an input shaft 11, an output shaft 3, and a gear assembly that drives and connects the two shafts. The input shaft 11 and the output shaft 3 rotate It is connected to the housing 1 and the axes of the two coincide. The gear assembly is arranged in the housing 1. The gear set includes a transmission gear 301, a double gear 2 and a ring gear 107. The transmission gear 301, the double gear 2 It is nested in the same radial plane as the ring gear 107 from inside to outside. The double gear 2 is eccentrically mounted on the input shaft 11 and the two are connected in rotation. The matching eccentric shaft section 1101, the double gear 2 is provided with the outer ring gear 201 meshing with the ring gear 107 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com