Low-viscosity liquid ring thickened oil conveying and stabilizing device

A technology for transporting stable and viscous fluids, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as complex structures, difficult-to-seal connections, and density differences, so as to avoid direct contact, reduce transport resistance, reduce The effect of flow obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

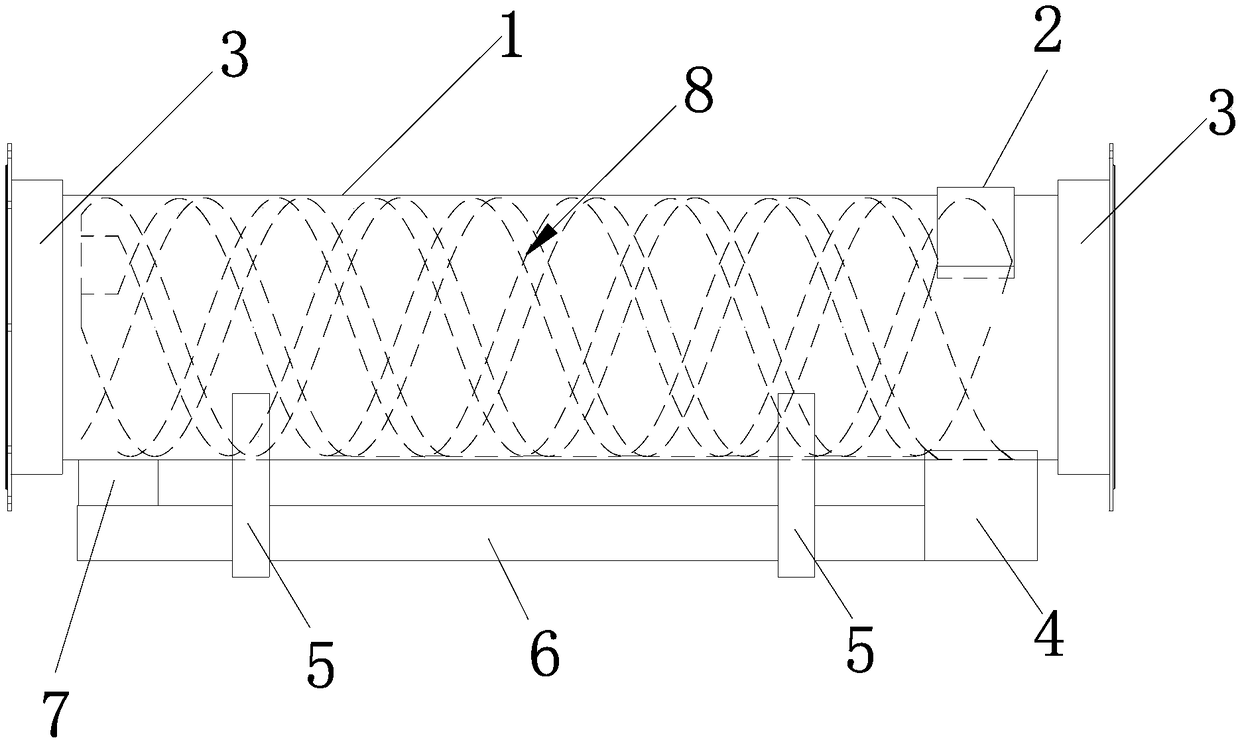

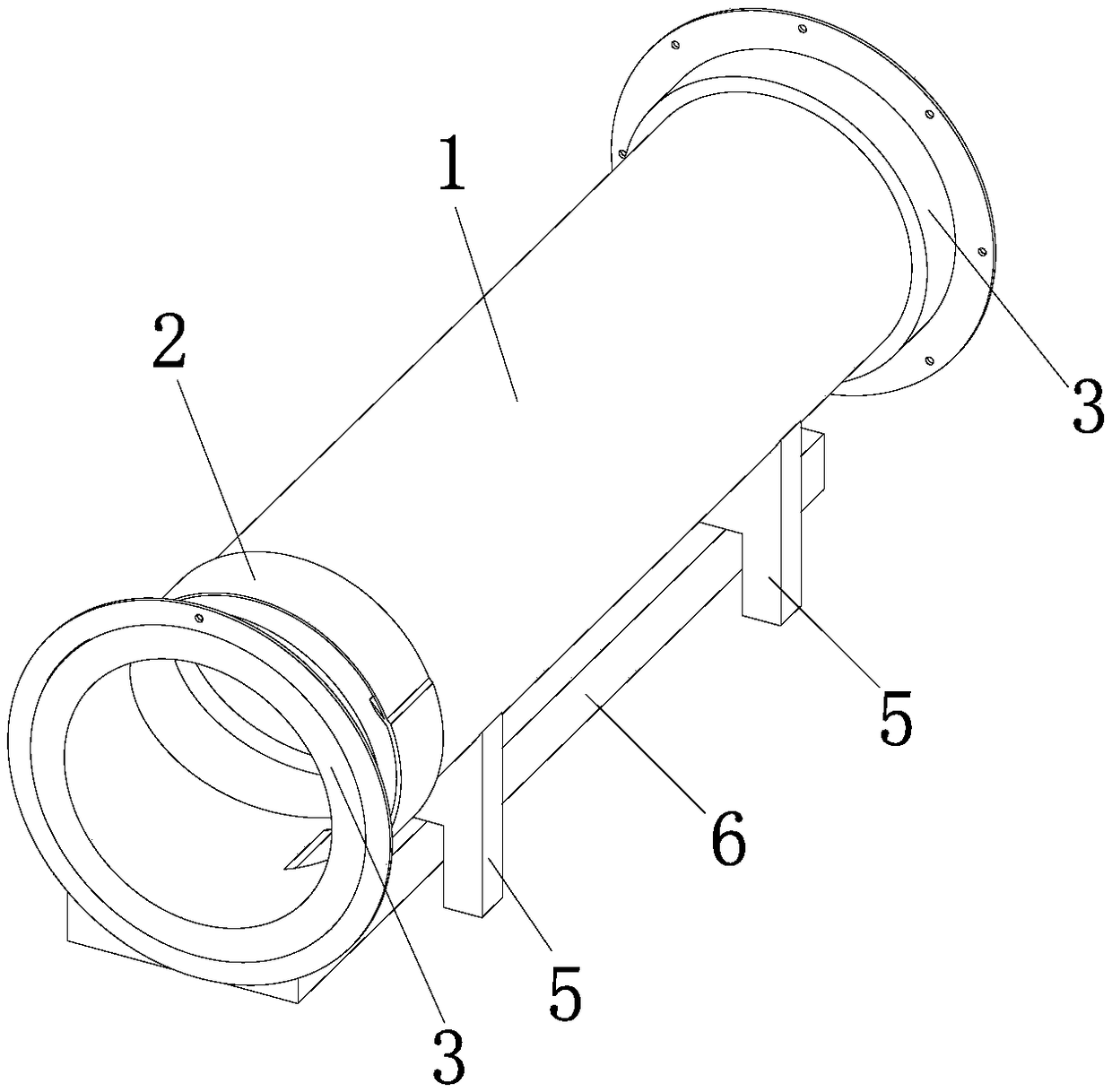

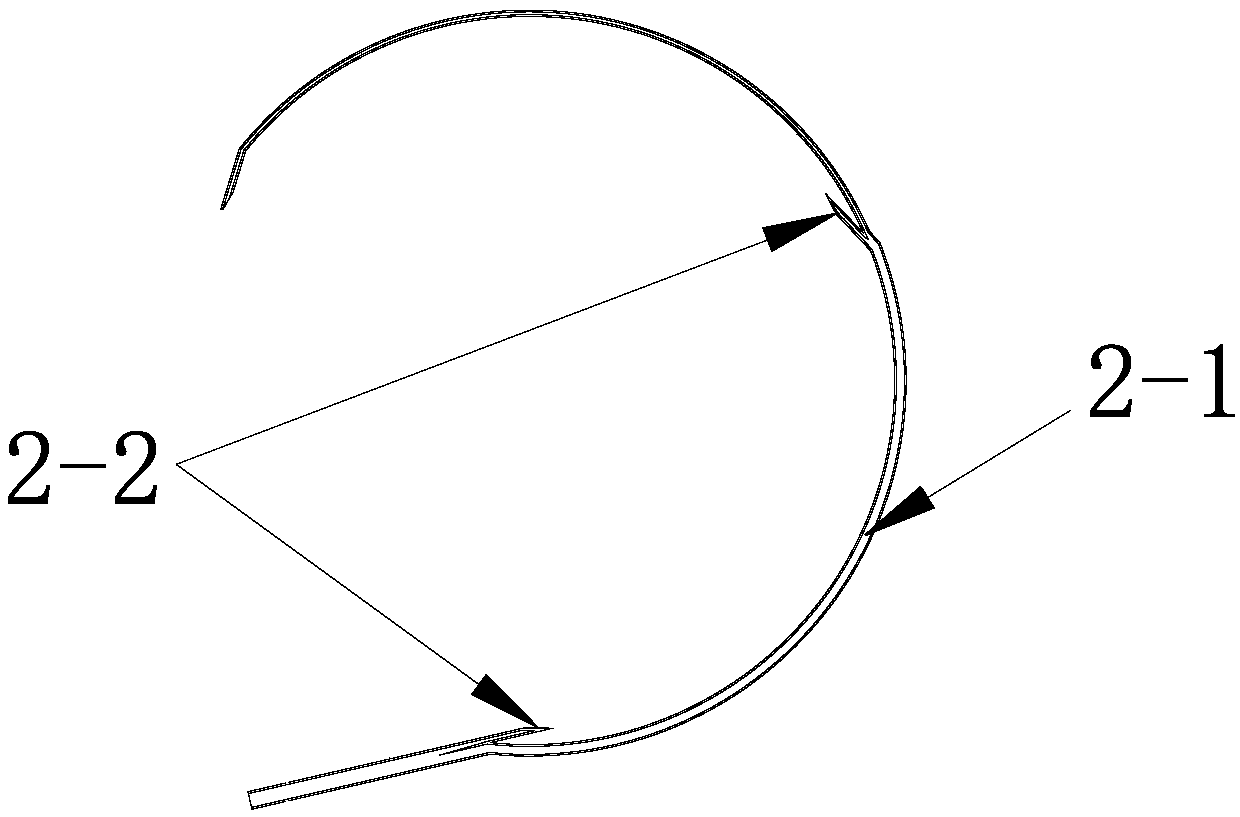

[0024] see Figure 1-Figure 3 , the low-viscosity ring heavy oil transportation stabilization device of this embodiment includes a pipe body 1, a delivery pump 4, a liquid storage tank 6 and a connecting pipe 2; wherein, the inner wall of the pipe body 1 is provided with a spiral groove 8, and the spiral groove The groove 8 extends from the beginning of the pipe body 1 to the end of the pipe body 1 along the axial direction; the inlet of the delivery pump 4 is connected to the liquid storage tank 6, and the liquid storage tank 6 is filled with low-viscosity liquid; One end of the connecting pipe 2 is connected to the outlet of the delivery pump 4 , and the other end passes through the pipe body 1 and is connected to the beginning of the spiral groove 8 .

[0025] see Figure 1-Figure 3 , the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com