Contact type cooling system adopting shape memory alloy

A memory alloy and cooling system technology, applied in the field of low-temperature cooling systems, can solve the problems of increased energy consumption and unstable operation of cooling devices, achieve simple structure, improve performance, avoid frequent start and stop or use complex frequency conversion technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A contact cooling system using a shape memory alloy of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

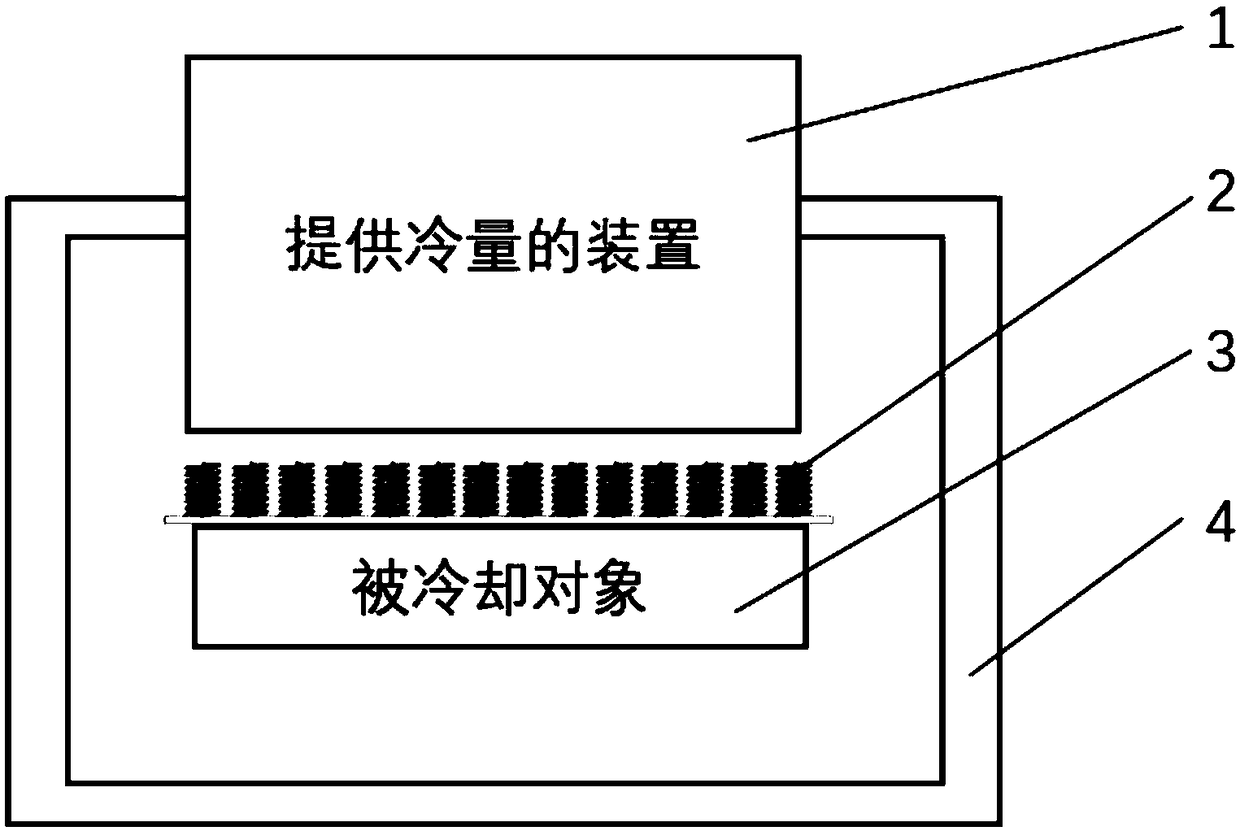

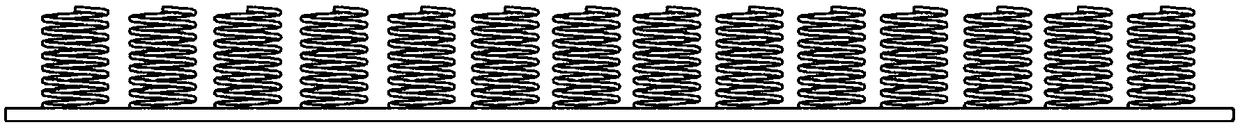

[0023] Such as figure 1 As shown, a contact cooling system using a shape memory alloy includes a refrigeration device 1 for providing cooling capacity, a shape memory alloy 2 , an object to be cooled 3 , and a vacuum dewar 4 . One end of the shape memory alloy 2 is fixed on the bottom plate, and is fixedly connected with the cooled object 3 through the bottom plate, and the other end is in contact with the refrigeration device 1 . Among them, the cold energy provided by the refrigeration device 1 is transferred to the shape memory alloy 2, and then transferred to the object to be cooled 3 through the bottom plate, so as to achieve the purpose of refrigeration. All three are placed in the vacuum dewar bottle 4, which is used to isolate the heat leakage of the environment.

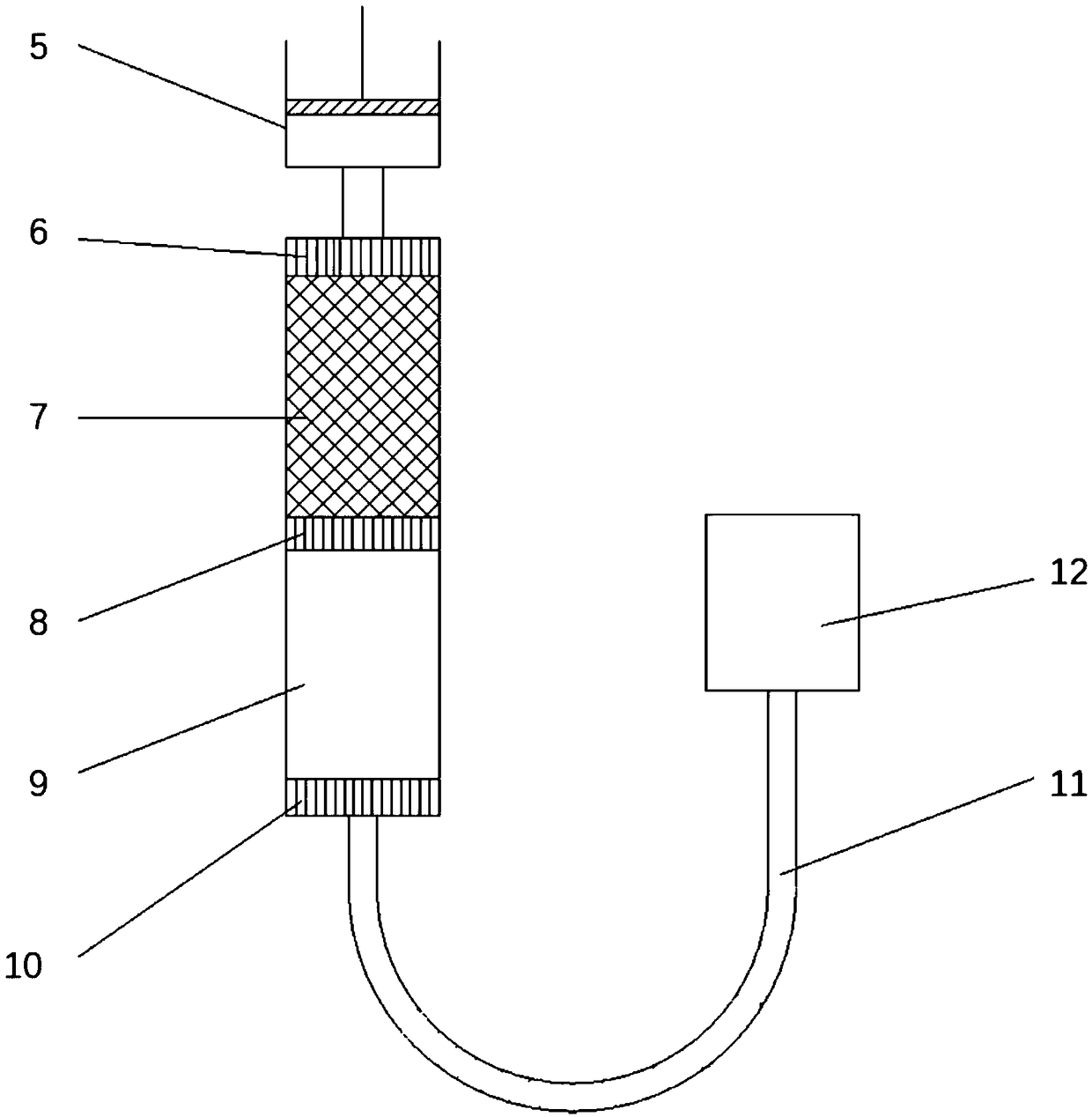

[0024] In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com