Radiation refrigeration particle and steam condensation recycling device

A radiation refrigeration and recovery device technology, applied in refrigeration and liquefaction, steam/vapor condensers, refrigerators, etc., can solve the problems of high adsorbent efficiency requirements, large power consumption, human and environmental harm to adsorbents, etc. Heat transfer performance, promotion of vapor condensation, and good condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

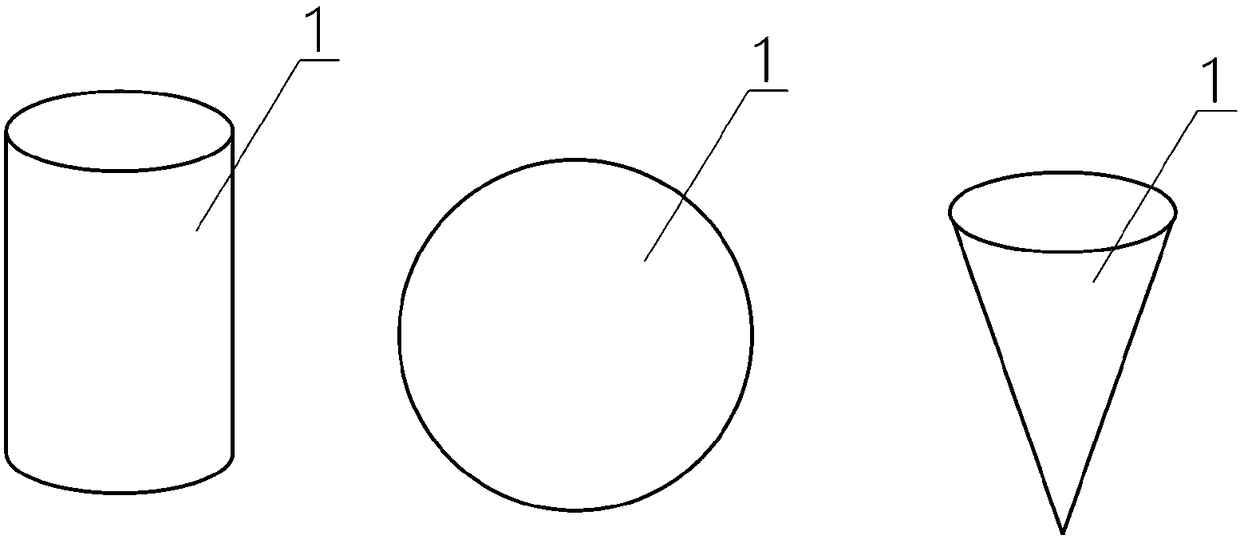

[0045] The first embodiment of the present invention provides a radiant cooling particle 1, see figure 1 As shown, the radiant refrigeration particles 1 are at least partly made of radiative refrigeration materials, suspended in the medium during use, and used to condense vapor in the medium.

[0046] Among them, the radiation cooling material is a material that can use infrared radiation to transfer heat from a heat source to a cold source in outer space through an atmospheric window of infrared radiation. Its refrigeration principle is similar to the natural refrigeration principle of the earth.

[0047] Those of ordinary skill in the art know that the energy of 200 petawatts that the earth absorbs from the sun every day is finally sent to the space near absolute zero in the form of radiation, so that its own temperature can be kept in balance within a certain range.

[0048]Radiation cooling materials can radiate energy in the form of infrared electromagnetic waves to achi...

Embodiment approach 2

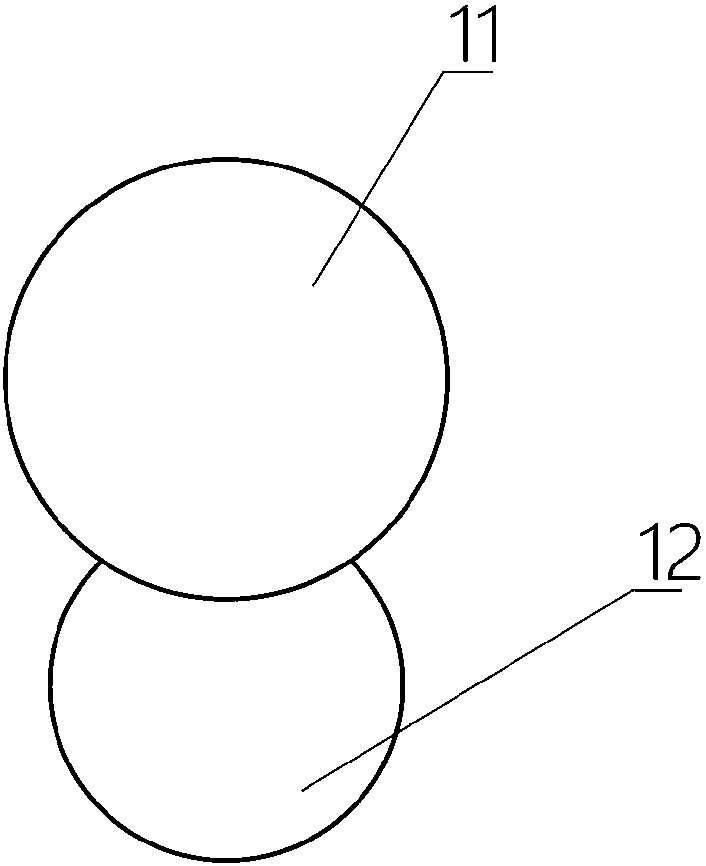

[0055] The second embodiment of the present invention provides a radiation cooling particle 1 . The second embodiment is a further improvement of the first embodiment, the main improvement is that, in the second embodiment of the present invention, see figure 2 As shown, the radiation cooling particles 1 include:

[0056] Condensate liquid 11 is made of radiation refrigeration material;

[0057] The hydrophobic liquid 12 is connected with the condensate liquid 11 and is made of a liquid-repellent material;

[0058] The average density of the hydrophobic liquid 12 is greater than the average density of the condensate liquid 11 .

[0059] Among them, see figure 2 As shown, the shape of the condensate 11 is not particularly limited, and a spherical shape with the largest surface area is preferred. The shape of the hydrophobic liquid 12 can be a spherical shape which is relatively easy to process.

[0060] According to the kind of medium, the material of hydrophobic liquid ...

Embodiment approach 3

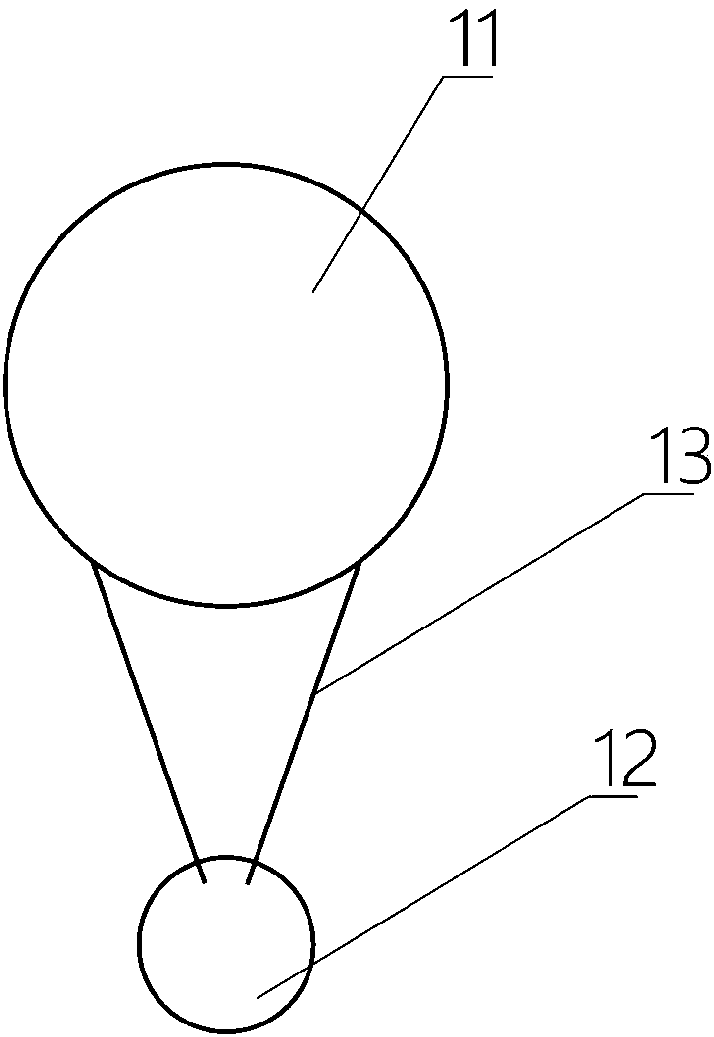

[0063] The third embodiment of the present invention provides a radiation cooling particle 1 . The third embodiment is a further improvement of the second embodiment, the main improvement is that, in the third embodiment of the present invention, see image 3 As shown, further, in this embodiment, the repellent liquid 12 is connected to the condensate liquid 11 through a thread 13 .

[0064] The condensing liquid 11 and the hydrophobic liquid 12 are connected by the wire 13 , which can make the exposed surface area of the condensing liquid 11 and the hydrophobic liquid 12 larger than the direct connection of the two. The droplets formed on the condensate liquid 11 can flow to the hydrophobic liquid 12 along the thread 13, which is more conducive to the collection of the condensate liquid.

[0065] In addition, the flexible connection of the wires 13 can also better ensure that the relative position of the hydrophobic liquid 12 is always below the condensate liquid 11 , so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com