Energy-saving hydrolyzer for preparation of polyacrylamide polymer by post-hydrolysis technique and method

The technology of polyacrylamide and hydrolyzer is applied to the energy-saving hydrolyzer and field for preparing polyacrylamide polymer by post-hydrolysis method, which can solve the problem of high energy consumption of polyacrylamide polymer and achieve high molecular weight quality, The effect of low energy consumption and shortening of system working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

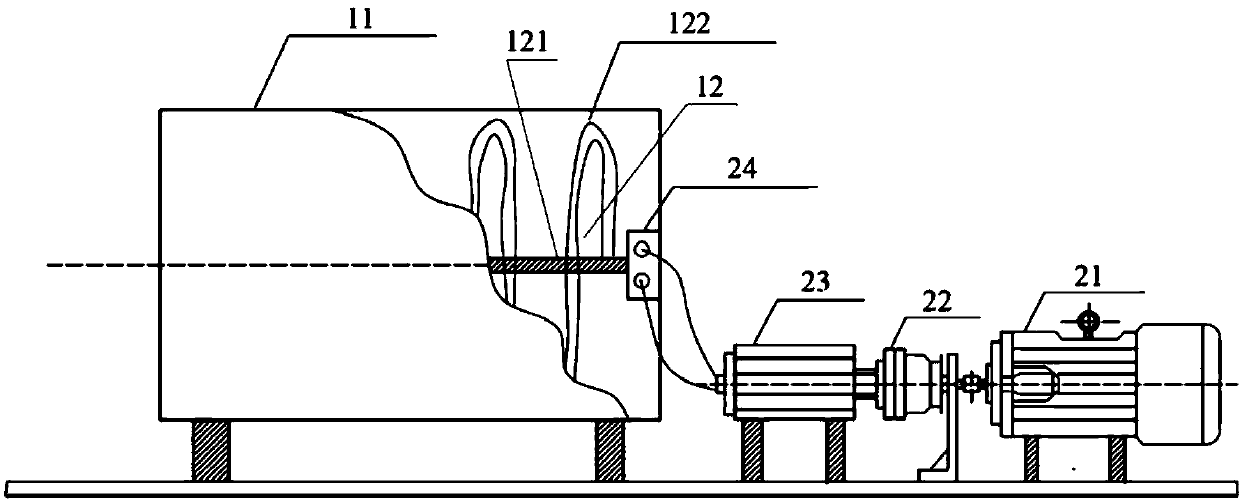

[0032] Below with 4 8 ton tanks (hydrolyzers) illustrate the use situation of the hydrolyzer equipment that provides the direct power that drives stirring device with hydraulic device of the present invention.

[0033] Firstly, the granulated polyacrylamide polymer is sent into the hydrolyzer through the conveying device. Raise the temperature to meet the process requirements. When the temperature is reached, according to the process requirements, add the required amount of solid sodium hydroxide into the hydrolyzer. At this time, the colloidal particles enter the state of hydrolysis, and the hydrolysis is carried out according to the time required by the process. After the hydrolysis is completed, the material is unloaded and sent to the next process link by the conveyor. Please refer to Table 1 for relevant process conditions and hydrolysis conditions.

[0034] Table 1

[0035]

Embodiment 2

[0037] Below with 4 5 ton tanks (hydrolyzers), illustrate the use of the hydrolyzer equipment that provides the direct power of driving stirring device with hydraulic device of the present invention.

[0038]Firstly, the granulated polyacrylamide polymer is sent into the hydrolyzer through the conveying device. Raise the temperature to meet the process requirements. When the temperature is reached, according to the process requirements, add the required amount of solid alkali into the hydrolyzer. At this time, the colloidal particles enter the state of hydrolysis, and the hydrolysis is carried out according to the time required by the process. After the hydrolysis is completed, the material is unloaded and sent to the next process link by the conveyor. Please refer to Table 2 for relevant process conditions and hydrolysis conditions.

[0039] Table 2

[0040]

[0041] It can be seen from the above examples that in the process of preparing polyacrylamide polymers by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com