Novel metallurgy and casting integration method

An integrated method and a new type of technology, applied in the field of smelting and casting, can solve the problems of coke and coal consumption, energy consumption and high production costs, and achieve the effects of reducing pig iron costs, no return to ore, and saving capital investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

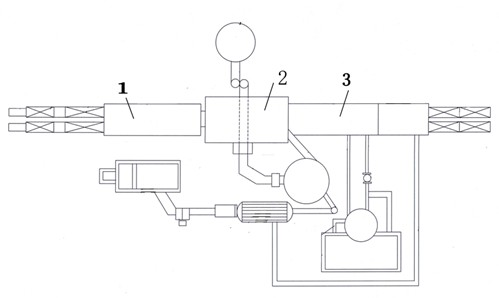

Image

Examples

Embodiment 1

[0012] The invention provides a novel metallurgical casting integration method, the steps of which are:

[0013] Step 1. Dry and dehydrate the coke powder, control the moisture to ≤8%, enter the horizontal pulverizer, crush it to a particle size of 1-3mm, and then mix it into the fine iron powder with a particle size of 170-200 mesh. Powder and coke powder are mixed at 70:30, then 6% binder and 1% high-alumina clay are added by weight, and then fully rolled and mixed by double-screw mixer and wheel-roller machine, and then enter the double-roller forming machine (or Vertical high-pressure forming machine) cold-pressed to form iron coke pellets with a diameter of 50mm or adjusted according to the requirements of the smelting process, wherein the binder is composed of sodium humic acid base, caustic soda: humic acid: water Mix at a weight ratio of 1:18:50, first add caustic soda to water, heat to 90°C, stir for 30 minutes, then add humic acid, heat to 95°C and stir for 2 hours. ...

Embodiment 2

[0018] The invention provides a novel metallurgical casting integration method, the steps of which are:

[0019] Step 1. Dry and dehydrate the coke powder, control the moisture to ≤8%, enter the horizontal pulverizer, crush it to a particle size of 1-3mm, and then mix it into the fine iron powder with a particle size of 170-200 mesh. Powder and coke powder are mixed at 70:30, then 7% binder and 2% high alumina clay are added by weight, and then fully rolled and mixed by double-screw mixer and wheel roller machine, and then enter the double-roll molding machine (or Vertical high-pressure forming machine) cold-pressed to form iron coke pellets with a diameter of 50mm or adjusted according to the requirements of the smelting process, wherein the binder is composed of sodium humic acid base, caustic soda: humic acid: water Mix at a weight ratio of 1:18:50, first add caustic soda to water, heat to 90°C, stir for 30 minutes, then add humic acid, heat to 95°C and stir for 2 hours.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com