Direct heat pump integrated variable pressure drying system and method

A technology that integrates pressure changing and drying systems. It is applied in heat pumps, drying gas layout, local agitation dryers, etc. It can solve the problems of large influence of ambient temperature and achieve the effect of low drying energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

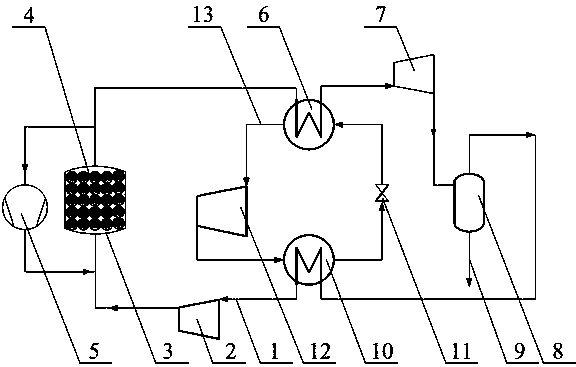

[0018] The following describes the working process of the direct heat pump integrated pressure swing drying system with reference to the accompanying drawings.

[0019] The system includes two closed cycles: closed air cycle and refrigerant refrigeration cycle;

[0020] In the closed air cycle, the circulating air 1 is compressed by the air compressor 2 and enters the drying box 3, where heat and moisture exchange occurs with the wet material 4 in the drying box 3, the wet material 4 is heated and dried, and the circulating air 1 is cooled and humidified It is divided into two paths: one path is mixed with the high-temperature air at the inlet of the drying box 3 through the circulation fan 5; the other path enters the hot side of the evaporator 6, is cooled by the refrigerant 13 on the cold side and condenses out liquid water, and then enters the expander 7 to the outside Expansion works and cools down to condense. The exhausted steam at the outlet of the expander enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com