Wood drying room with meshed combined type diversion mechanism

A diversion mechanism and wood drying technology, which is applied in the field of wood drying chambers, can solve problems such as inability to baffle, detach, and unstable connection of baffles, and achieve the effects of avoiding occlusal dislocation, increasing friction, and enhancing connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

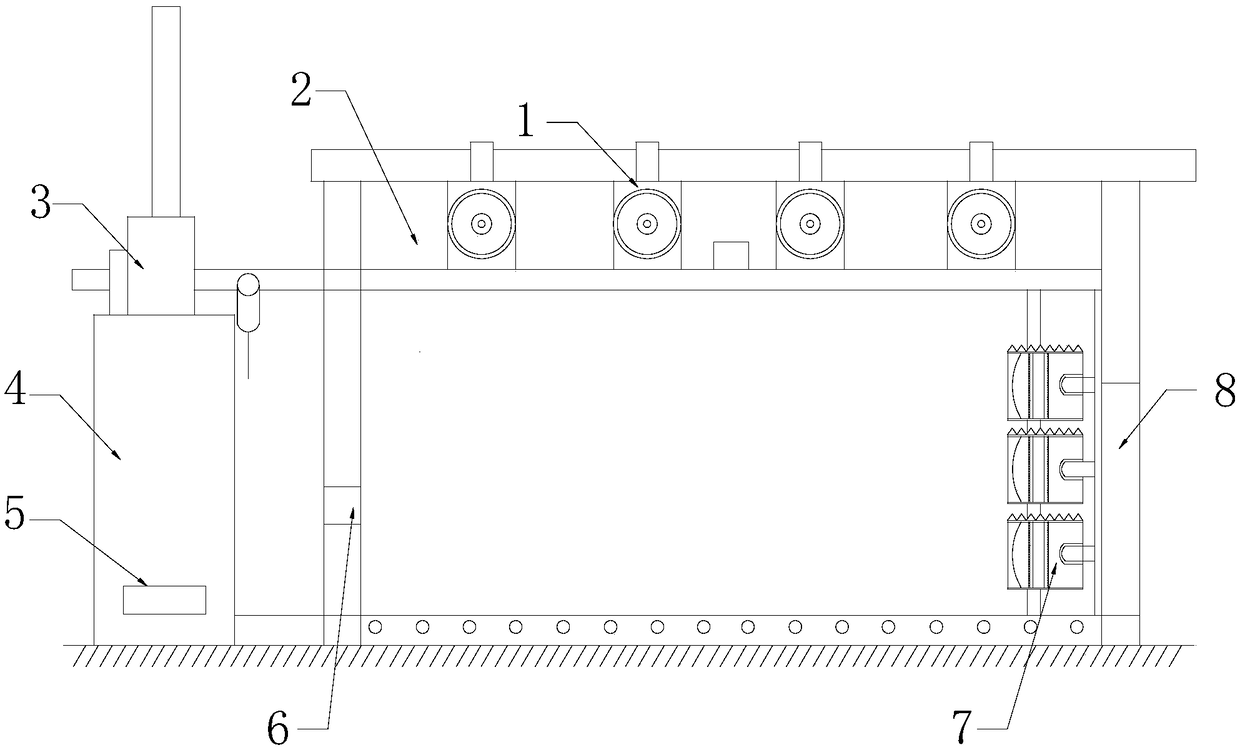

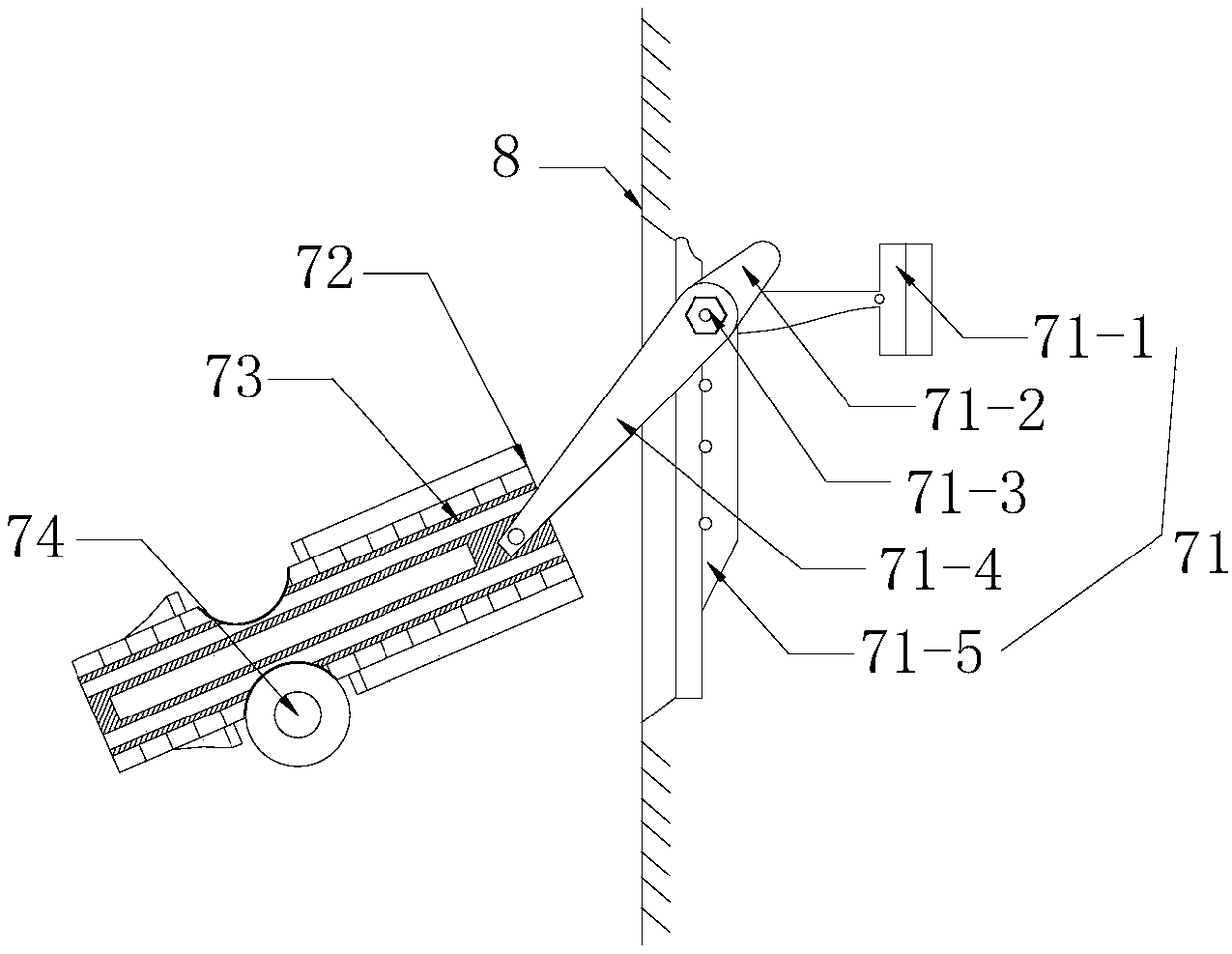

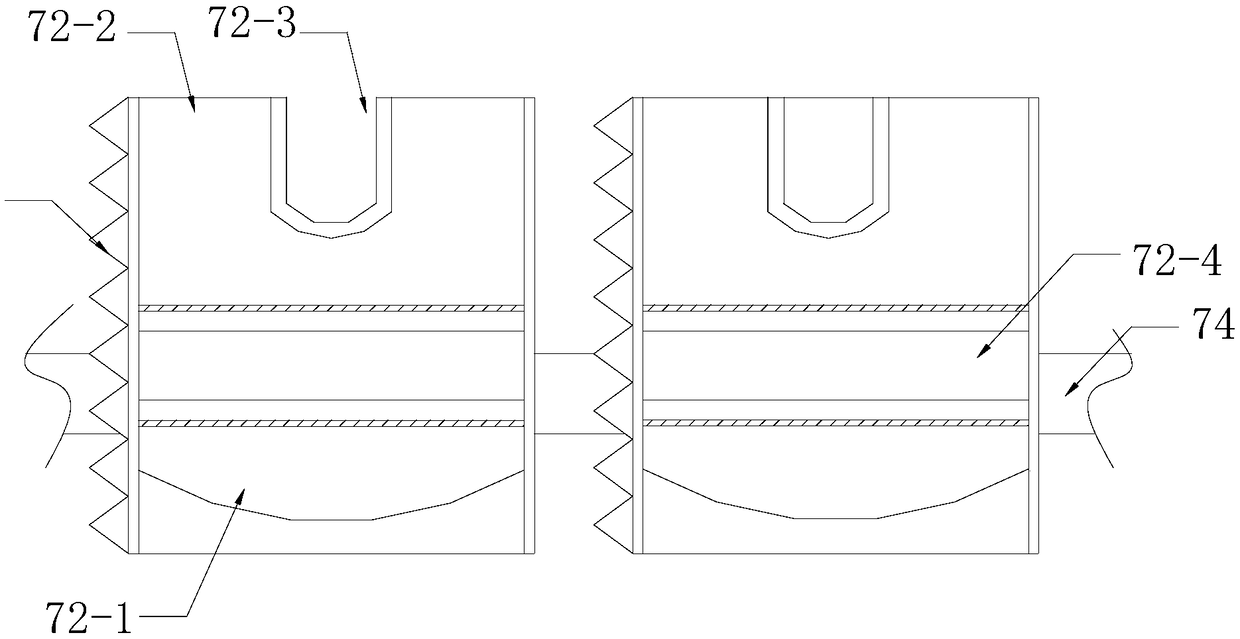

[0024] see Figure 1-Figure 4 , the present invention provides a wood drying chamber with an interlocking combined diversion mechanism, the structure of which includes a high-temperature circulation fan 1, a windshield 2, a centrifugal blower 3, a hot blast stove 4, a furnace mouth 5, an observation port 6, and a diversion structure 7 , chamber body 8, two or more high-temperature circulation fans 1 are installed horizontally side by side on the top of the chamber body 8, and a high-temperature circulation fan 1 is installed between the two centrifugal blowers 3, and the high-temperature circulation fan 1 is located between The centrifugal blower 3 of the same horizontal line is connected, and the centrifugal blower 3 is located outside the chamber body 8. The centrifugal blower 3 is installed on the top of the hot blast stove 4 and the two are connected. The bottom end of the hot blast stove 4 is provided with a furnace mouth 5 , the side panel of the chamber body 8 close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com