A kind of bearing roller plastic deformation experiment device and using method thereof

A technology of plastic deformation and bearing rollers, applied in the direction of mechanical bearing testing, etc., can solve the problems of not being able to respond well to the deformation of a single roller, unable to objectively reflect the deformation of the rollers, etc., to achieve easy replacement, improve accuracy, The effect of high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

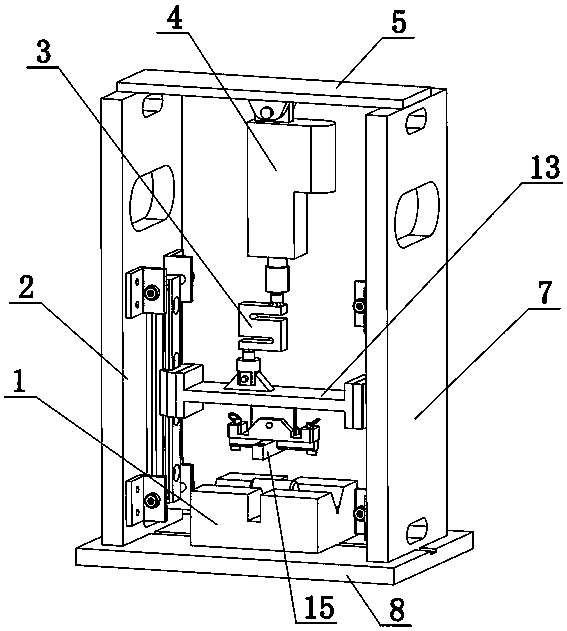

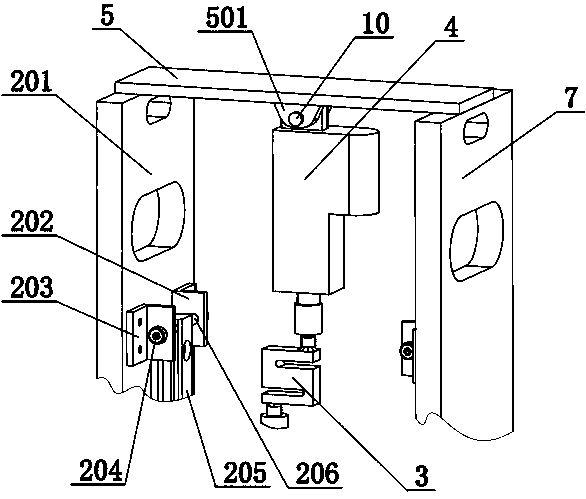

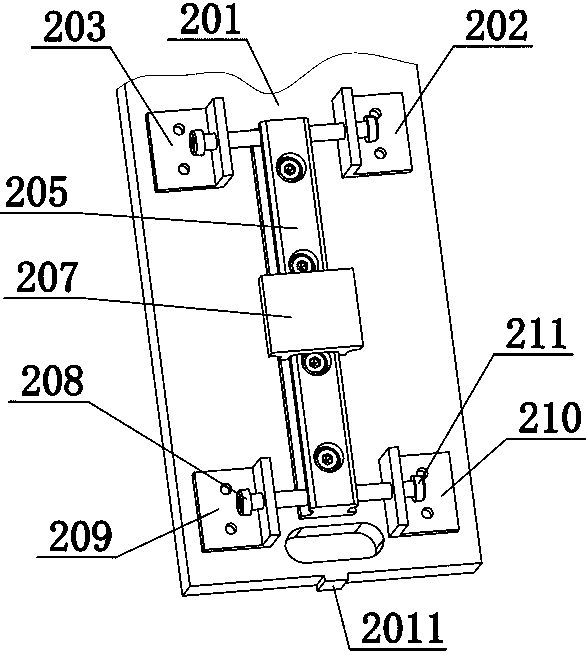

[0046] combine Figure 1-12 , a bearing roller plastic deformation experiment device of the present invention comprises a roller seat 1, a left guide support mechanism 2, a pressure sensor 3, an electric push rod 4, a horizontal beam 5, a right guide support mechanism 7, a bottom plate 8, a pin Shaft 10, pin shaft 2 11, connector 12, lifting beam 13, pressure plate 14, contact plate 15, pin shaft 3 16, left spring pin 17, left pull ring 18, left spring 19, right spring pin 20, right Pull ring, right spring, elastic ring 21, control system, described base plate 8 is the structure of left and right symmetry, the left and right sides of upper side of base plate 8 are respectively fixed left guide support mechanism 2, right guide support mechanism 7, left side The guide support mechanism 2 and the right guide support mechanism 7 are left-right symmetrical about the left-right symmetrical plane of the bottom plate 8 . Described left guide support mechanism 2 comprises left vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com