A kind of giant magneto-impedance effect magnetic sensitive sensor and preparation method

A magnetic sensor and giant magneto-impedance technology, applied in the field of sensors, can solve the problems of cumbersome process, low mass production yield, easy uneven film preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

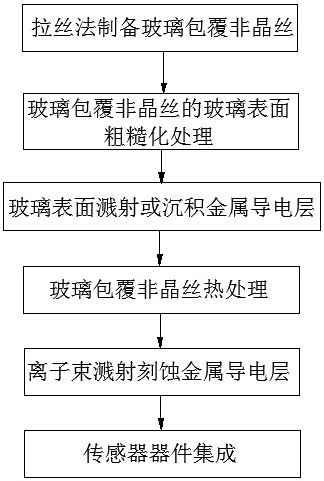

[0043] Such as figure 2Shown, a kind of preparation method of giant magneto-impedance effect magnetosensitive sensor, comprises the following steps:

[0044] Step 1. Select glass-coated amorphous wire as the magnetic sensitive material 1, and obtain glass-coated amorphous wire with a diameter of 8-180 μm by wire drawing method, and set aside;

[0045] Step 2: roughen the glass surface of the glass-coated amorphous wire obtained in step 1, and then fix the treated glass-coated amorphous wire on a spin stand; wherein, the glass surface is roughened using What is HF solution or NaOH solution;

[0046] Step 3, the spin frame drives the glass-coated amorphous wire to spin at different rates, and magnetron sputtering or vapor deposition of a metal conductive layer 4 on the glass surface of the spinning glass-coated amorphous wire;

[0047] Step 4, heat-treat the glass-coated amorphous wire with the metal conductive layer 4, so that the glass-coated amorphous wire can obtain the b...

Embodiment 1

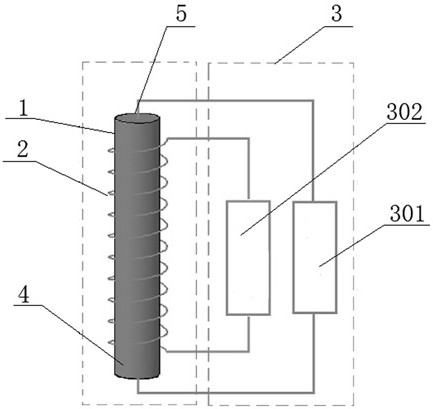

[0061] A giant magneto-impedance effect magnetosensitive sensor, comprising a magnetosensitive material 1, a three-dimensional miniature induction coil 2 and a circuit part 3, the circuit part 3 comprising a drive circuit 301 and a signal acquisition and processing circuit 302;

[0062] The surface of the magnetic sensitive material 1 is provided with a metal conductive layer 4, the metal conductive layer 4 is etched at intervals along the circumferential direction and a three-dimensional miniature induction coil 2 is formed on the magnetic sensitive material 1, the magnetic sensitive material 1 and the three-dimensional miniature induction coil 2 A magnetic sensitive sensing unit is formed, and several magnetic sensitive sensing units are combined into the groove of the sensor substrate to form a magnetic sensitive sensor. The two ends of the magnetic sensitive sensor are respectively provided with probe parts 5, and between the probe parts 5 at both ends The driving circuit 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com