COMSOL model-based manufacturing method of solid-state lithium battery

A production method and solid-state lithium technology, which can be used in secondary batteries, circuits, electrical components, etc., can solve the problems of materials and time waste, and achieve the effect of saving cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

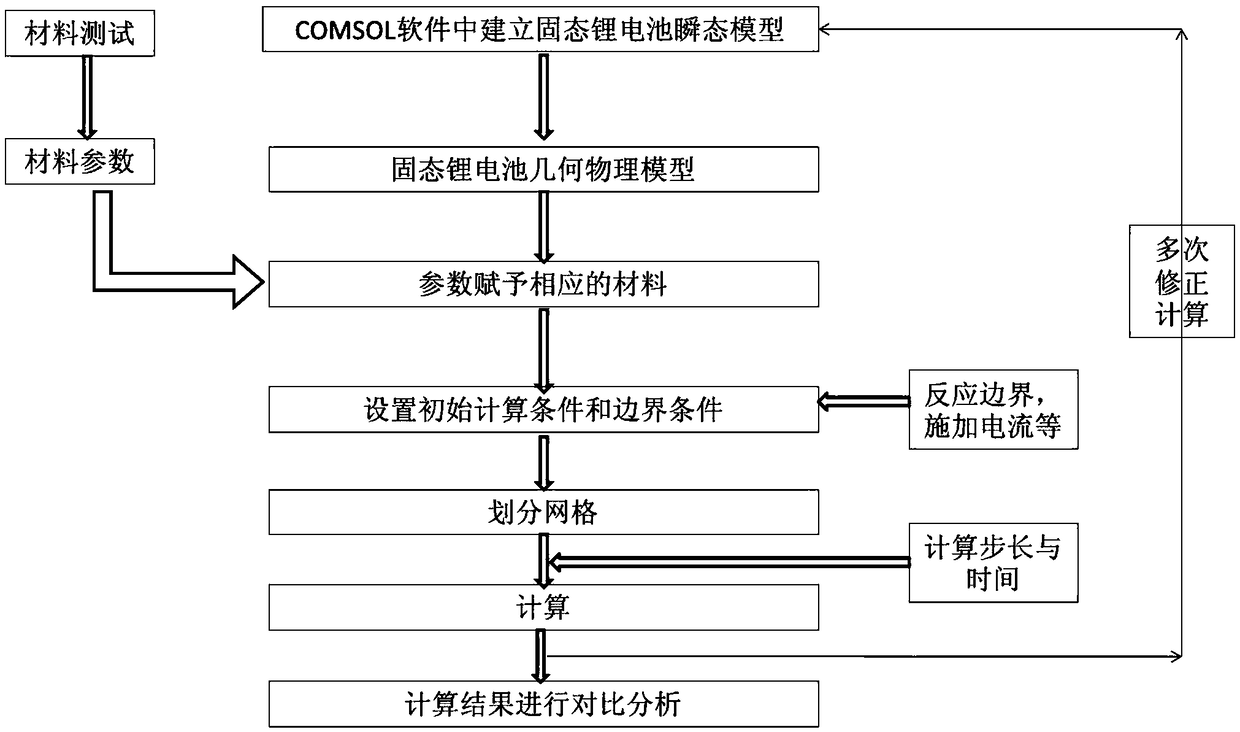

[0027] A kind of method based on COMSOL model solid-state lithium battery design, comprises the steps:

[0028] 1) Obtain the basic parameters of materials in solid-state lithium batteries Li / LiPON / LCO by electrochemical methods such as AC impedance, constant current intermittent titration, cyclic voltammetry, and equilibrium potential curves

[0029] 2) Enter the COMSOL software interface, create a new one-dimensional model, select the secondary current module and the PDE general module in the electrochemical module, and select the transient state. Add parameters and plug-in functions to definitions.

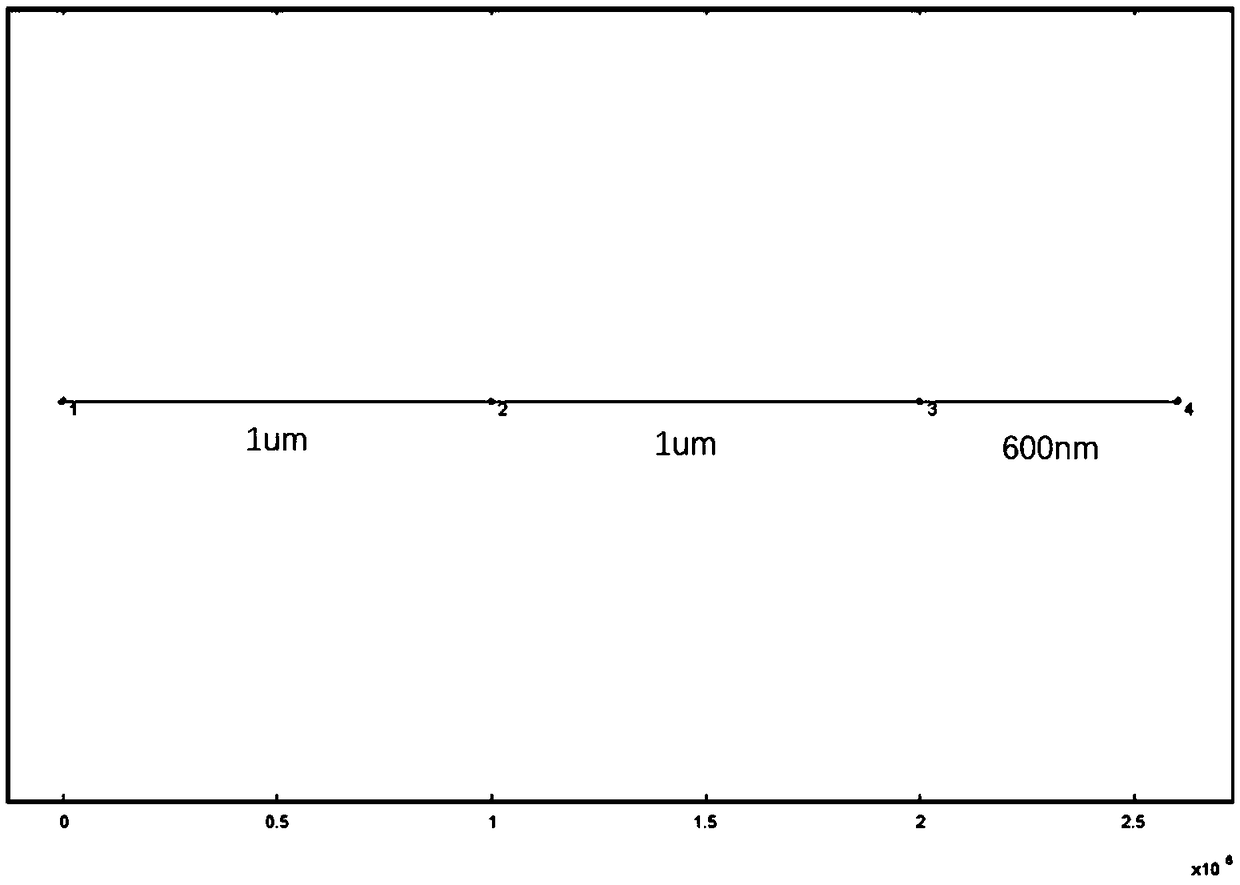

[0030] 3) Set up a one-dimensional model of a solid-state lithium battery. The thicknesses of the negative electrode, electrolyte, and positive electrode are 1um, 1um, and 600nm in sequence. Both the negative electrode and the positive electrode use the electrode mode, and the material parameters in the corresponding area are set. The PDE module is applied to the positive ele...

Embodiment 2

[0038] A kind of method based on COMSOL model solid-state lithium battery design, comprises the steps:

[0039] 1) Obtain the basic parameters of materials in solid-state lithium batteries Li / LiPON / LCO by electrochemical methods such as AC impedance, constant current intermittent titration, cyclic voltammetry, and equilibrium potential curves

[0040] 2) Enter the COMSOL software interface, create a new one-dimensional model, select the secondary current module and the PDE general module in the electrochemical module, and select the transient state. Add parameters and plug-in functions to definitions.

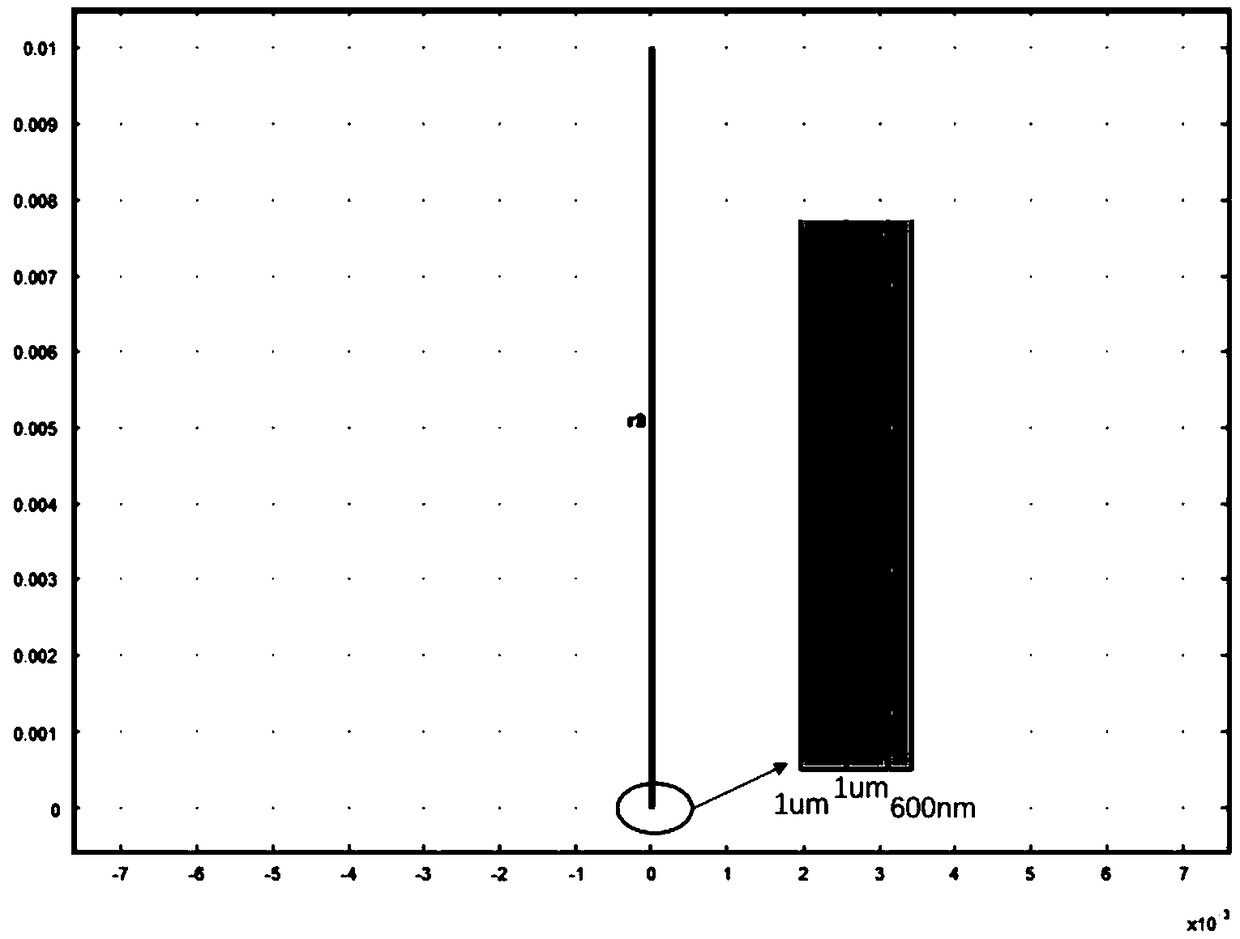

[0041] 3) Set up four one-dimensional models of solid-state lithium batteries. The thicknesses of the negative electrode and electrolyte are 1um and 1um in sequence, and the thicknesses of the positive electrode are 600nm, 3um, 6um, and 12um in sequence. Both the negative electrode and the positive electrode use the electrode mode, and the material parameters in the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com