Preparation method and use of a carbon-based composite material

A carbon-based composite material and cotton cloth technology, which is applied in the manufacture of hybrid/electric double layer capacitors and hybrid capacitor electrodes, can solve the problems of high cost, unsuitable for large-scale use, and poor carbon cloth effect, and achieve low cost and convenience Methods of preparation, effects of ease of diffusion and transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

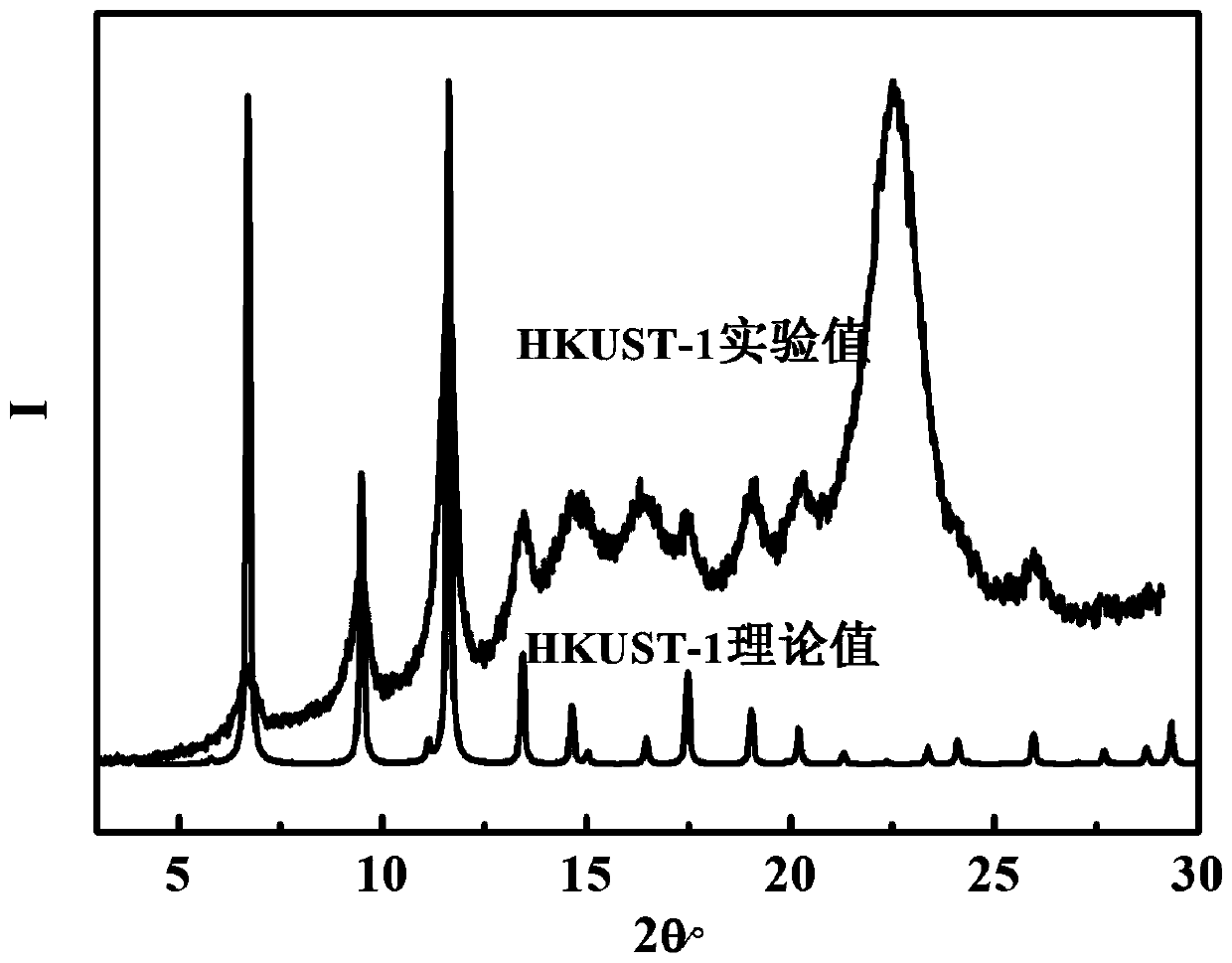

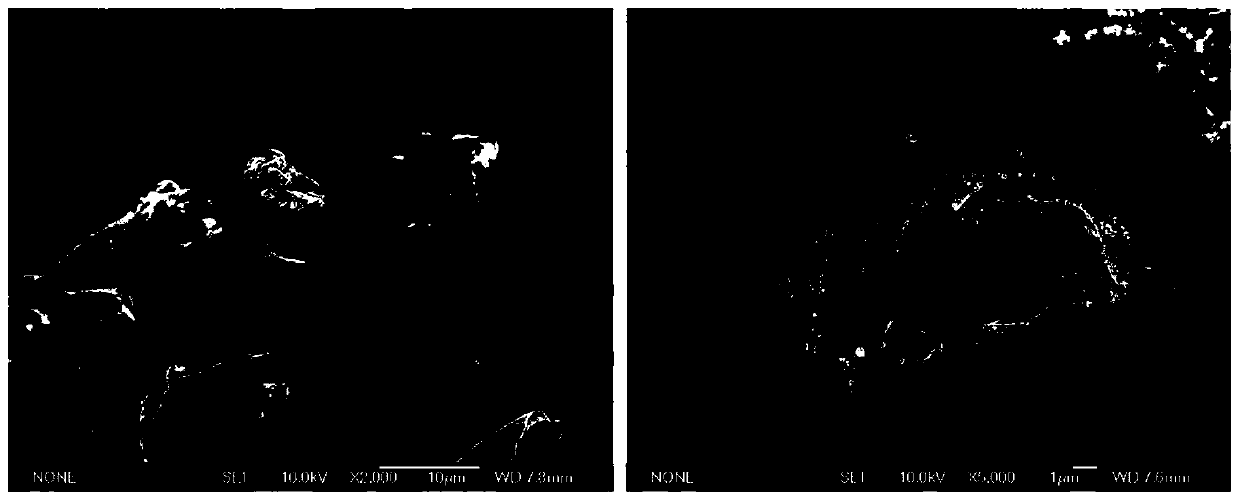

[0062] 1) Preparation of HKUST-1 metal organic framework thin film

[0063] Weigh copper acetate and trimesic acid, dissolve them in pure ethanol solution, and prepare 500ml of solutions with concentrations of 1mmol / L and 0.4mmol / L respectively.

[0064] The prepared solutions are respectively connected to the circulation pump device to provide the reaction raw materials, and each pump correspondingly draws a solution. Then, the cotton cloth modified with hydroxyl groups was used as the growth substrate, and the cotton cloth was fixed in the reaction pool. Finally, set the time for extracting the solution, soaking time and reaction time, and start the cycle after the setting is completed.

[0065] Wherein, the immersion amount of copper acetate solution is advisable to have not crossed cotton cloth, and immersion time is 15 minutes, and standing reaction time is 3 minutes after immersion, and soaks 1 minute with pure ethanol after reaction to remove residual reaction raw mate...

Embodiment 2

[0073] 1) Preparation of ZIF-8 metal-organic framework films

[0074] Weigh zinc acetate and dimethylimidazole, dissolve them in pure ethanol solution, and prepare 500ml of solutions with concentrations of 1mmol / L and 0.4mmol / L respectively.

[0075] The prepared solutions are respectively connected to the circulation pump device to provide the reaction raw materials, and each pump correspondingly draws a solution. Then, the cotton cloth modified with hydroxyl groups was used as the growth substrate, and the cotton cloth was fixed in the reaction pool. Finally, set the time for extracting the solution, soaking time and reaction time, and start the cycle after the setting is completed.

[0076] Wherein, the immersion amount of zinc acetate solution is advisable to have not crossed cotton cloth, immersion time is 15 minutes, after immersion standstill reaction time is 3 minutes, after reaction, soak 1 minute with pure ethanol to remove residual reaction raw material. Afterward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com