Isolation switch

A technology of isolating switch and switchgear, which is applied in the direction of electric switch, air switch parts, high-voltage air circuit breaker, etc., can solve the problems of increasing the distance between charged bodies, large insulation distance, and old-fashioned structure, so as to improve safety and reliability. Effect of shortening insulation distance and simplifying assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

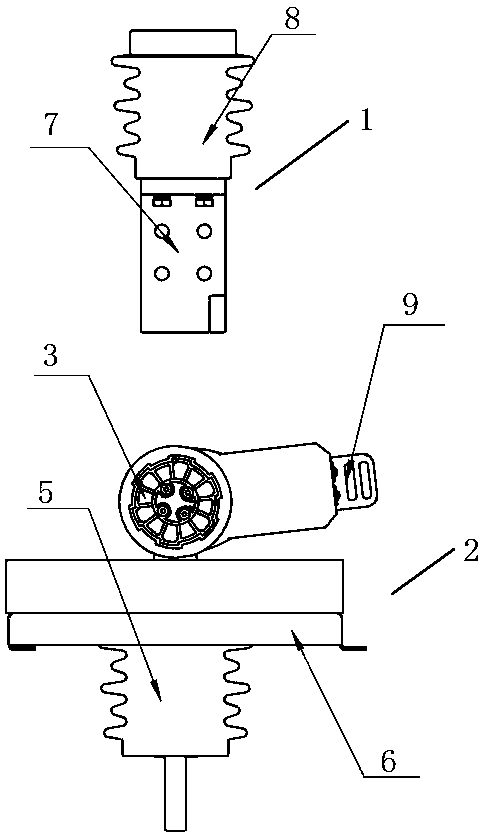

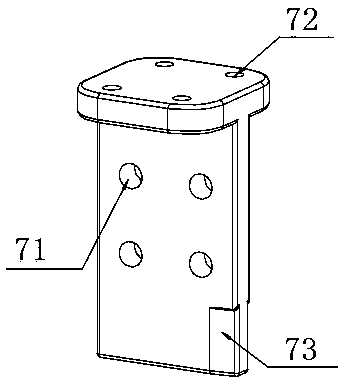

[0034] Such as figure 2 and 4 As shown, the isolating switch includes a static contact seat 1 and a disconnecting switch body 2, the static contact seat 1 and the isolating switch body 2 are separately arranged, the static contact seat 1 is installed inside the switchgear 10, and the isolating switch body 2 is installed in the static contact seat 1 lower part. The static contact seat 1 includes a T-shaped static contact piece 7 and a supporting insulator 8. The upper side of the static contact piece 7 is fixed on the supporting insulator 8, and the lower side is opened or closed with the isolating switch body 2. When closing, the static contact The sheet 7 is overlapped with the disconnector body 2 on the same straight line.

[0035] figure 2 and 4 , combine Figure 5 As shown, the isolating switch body 2 includes a moving contact piece assembly 9, an insulating segmented shaft 3, a conductor 4, an insulating bracket 5 and a supporting frame 6, the insulating bracket 5 ...

Embodiment 2

[0041] This embodiment is illustrated by taking three sets of static contact seats and a disconnector body as examples, and there are three sets of insulated segmented shafts. The structures of the single static contact seat and the main body of the isolating switch are the same as those in Embodiment 1, and will not be repeated here. Just explain the assembly relationship between each group of isolating switch bodies.

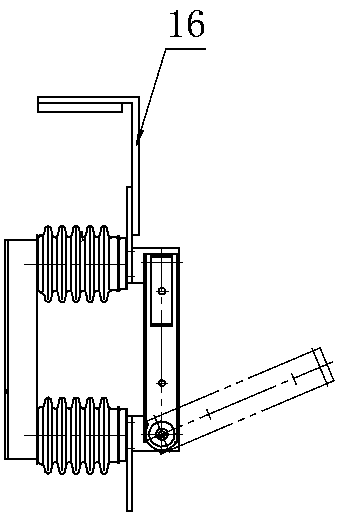

[0042] Such as Figure 9-10 As shown, after the assembly of the insulating segmented shaft 3, it is set on the outside of the movable contact piece assembly 9, coaxial with the rotating shaft pin 14 (same as described in Embodiment 1), and the insulating segmented shaft 3 is passed between each group of isolating switch bodies 2. The connection is an integral structure, and the outer ends of the insulating segmented shaft 3 are respectively provided with a left end 31 and a right end 32, and the left end 31 and the right end 32 are connected with the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com