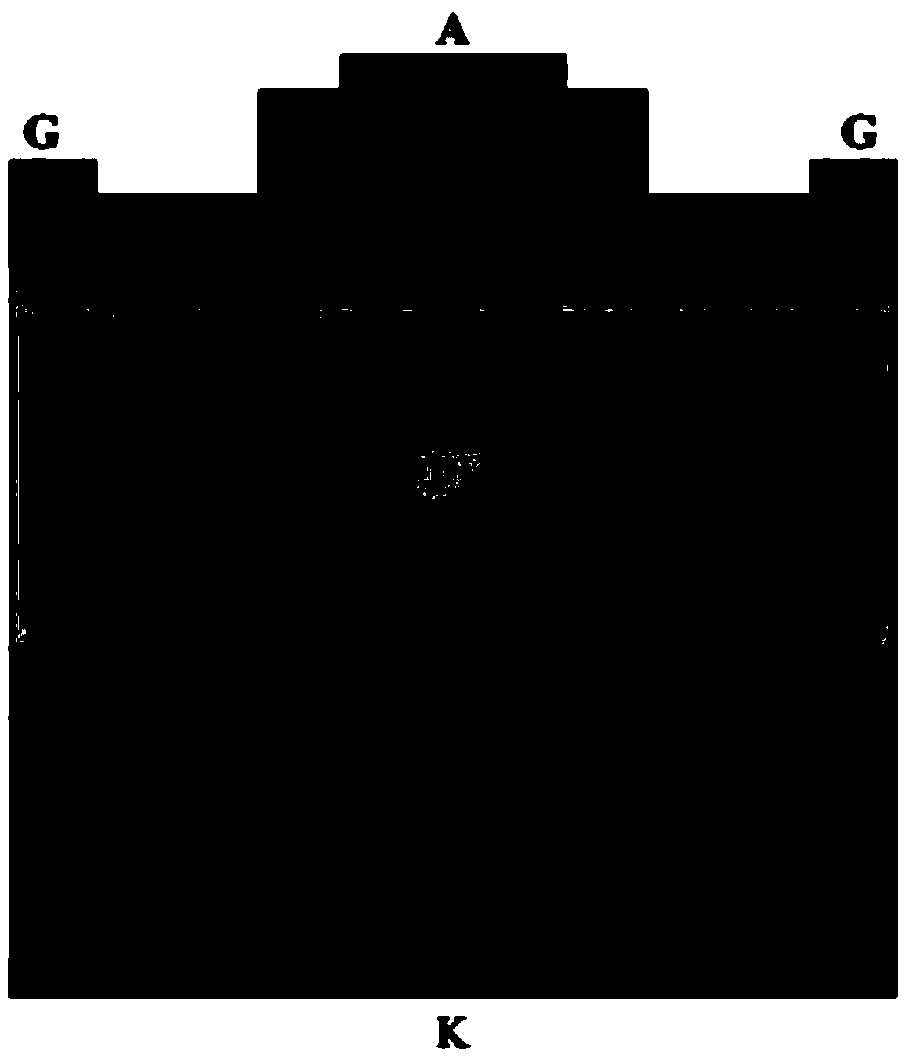

Silicon carbide gate-turn-off thyristor and manufacturing method thereof

A silicon carbide gate and thyristor technology, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of poor resistance to dV/dt, uneven distribution of on-state dynamic current, and poor resistance to dI/dt. and other problems, to achieve the effect of improving the ability to resist dI/dt and dV/dt, reducing the current density of the collector and enhancing the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

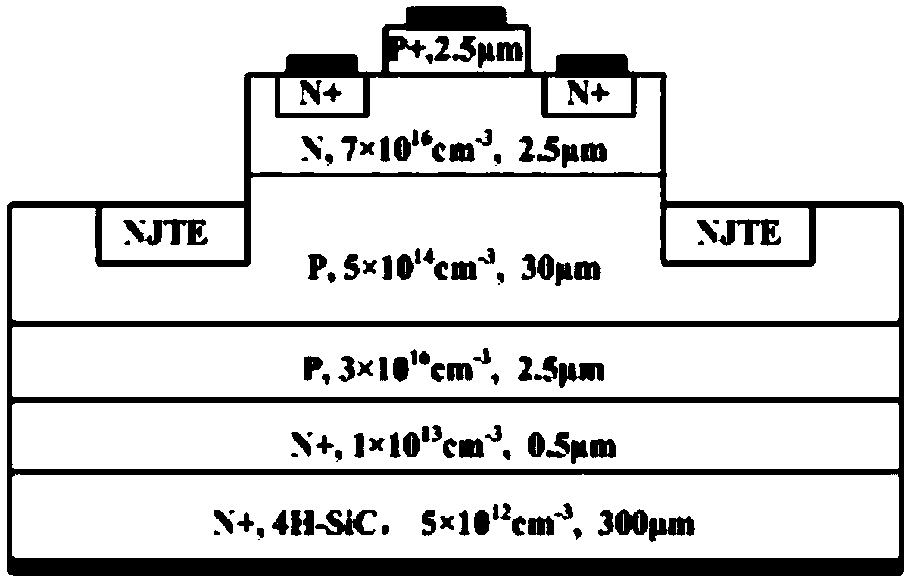

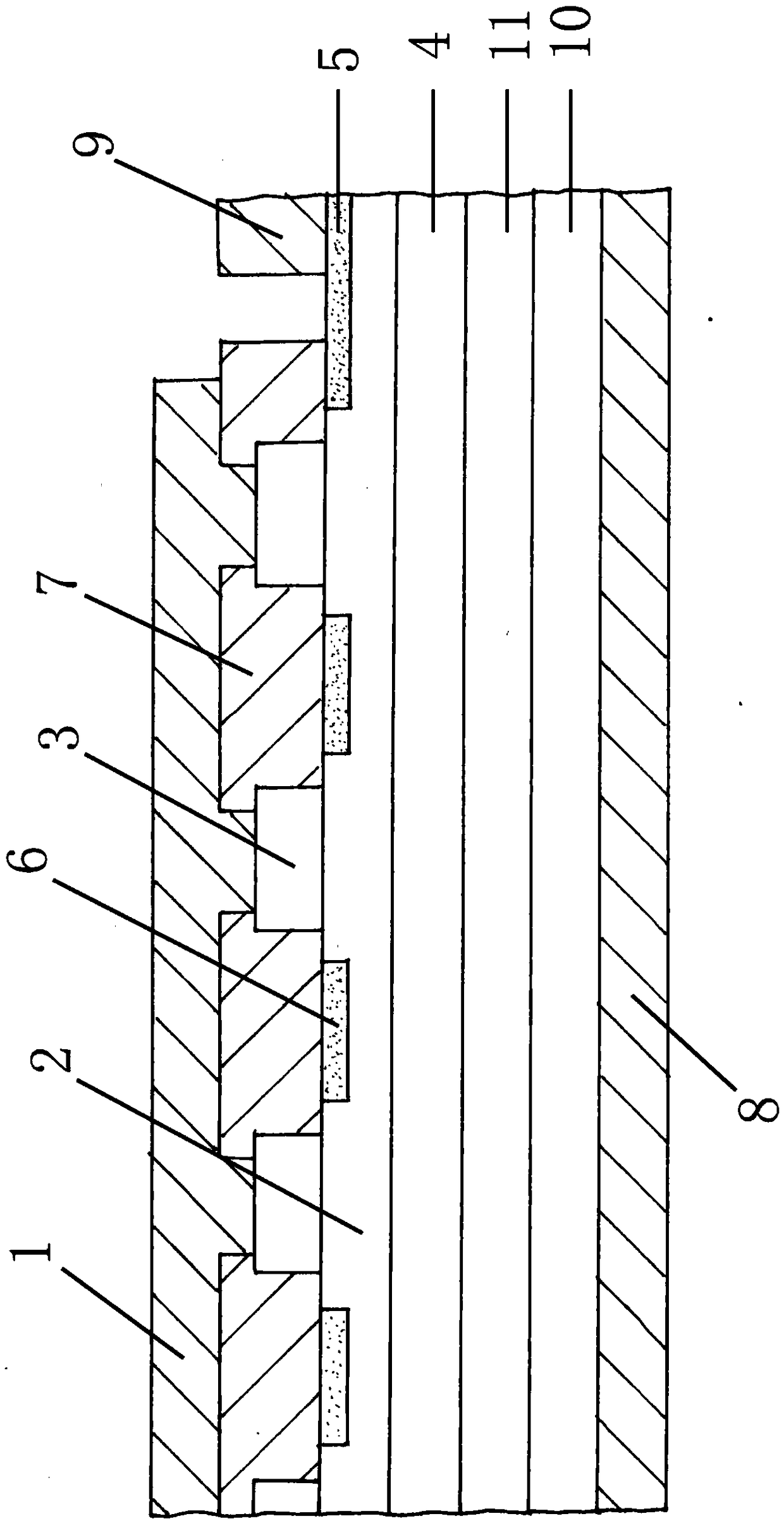

[0050] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0051] First of all, the shape of the P-type emission area of the upper tube of the present invention can be rectangular, square, hexagonal, circular, trapezoidal, triangular or other shapes, as well as graphics of various combinations of shapes, usually a rectangle. For the sake of simplicity, many descriptions in the specification use a rectangle for the P-type emitter region, a rectangle for the N-type base region, and a rectangle for the N-type base concentration region. This is an interdigitated structure of a common power transistor.

[0052] Secondly, the mask pattern mentioned in the present invention refers to the GDS pattern of the mask. This is the norm in the industry. To make the mask plate, first use computer-aided design to make the GDS data tape of the graphic generator, and draw the GDS graphics ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com