Brushless motor stator and brushless motor

A brushless motor and stator technology, used in synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc. Inter-turn short circuit risk, high efficiency, good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

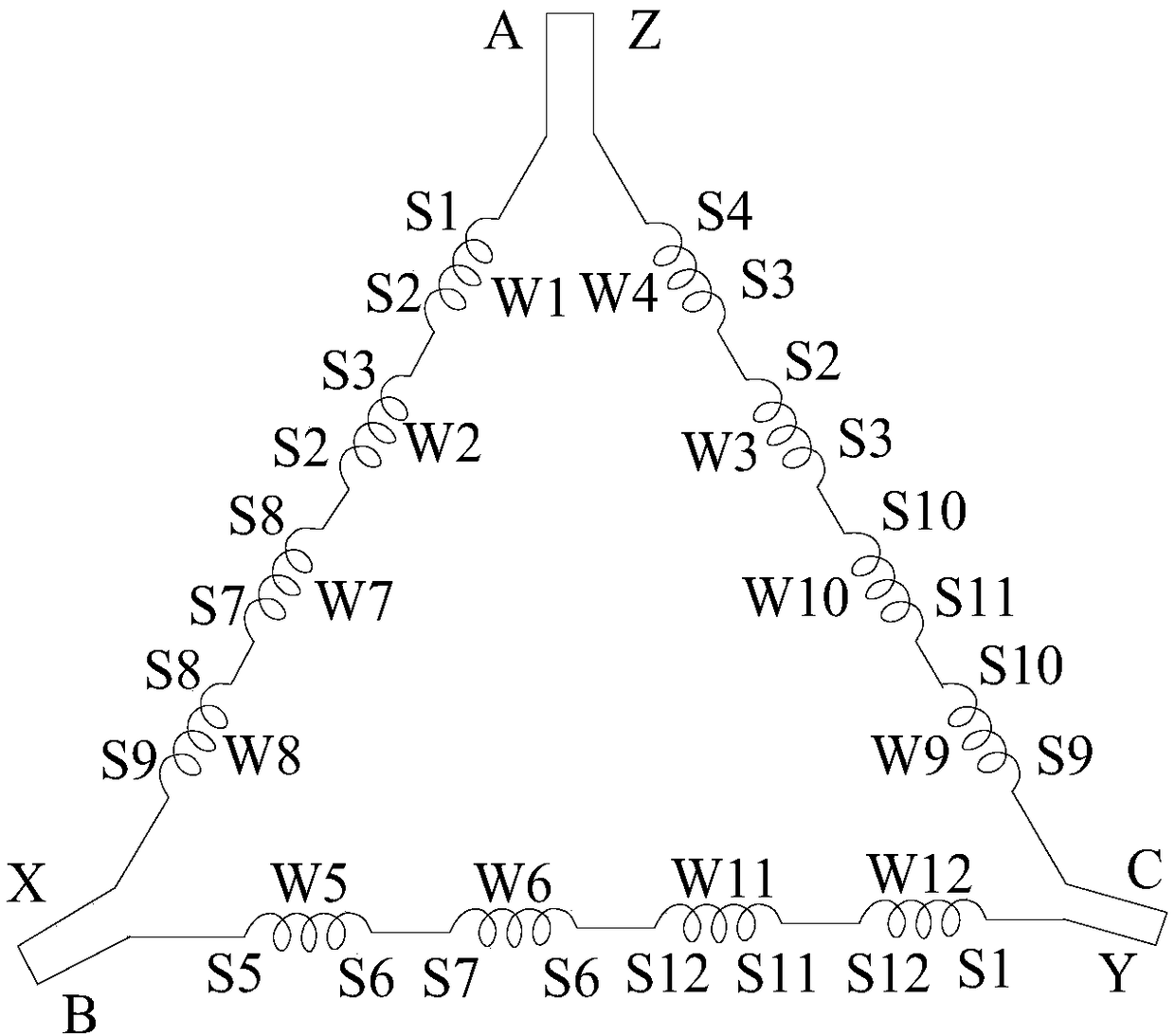

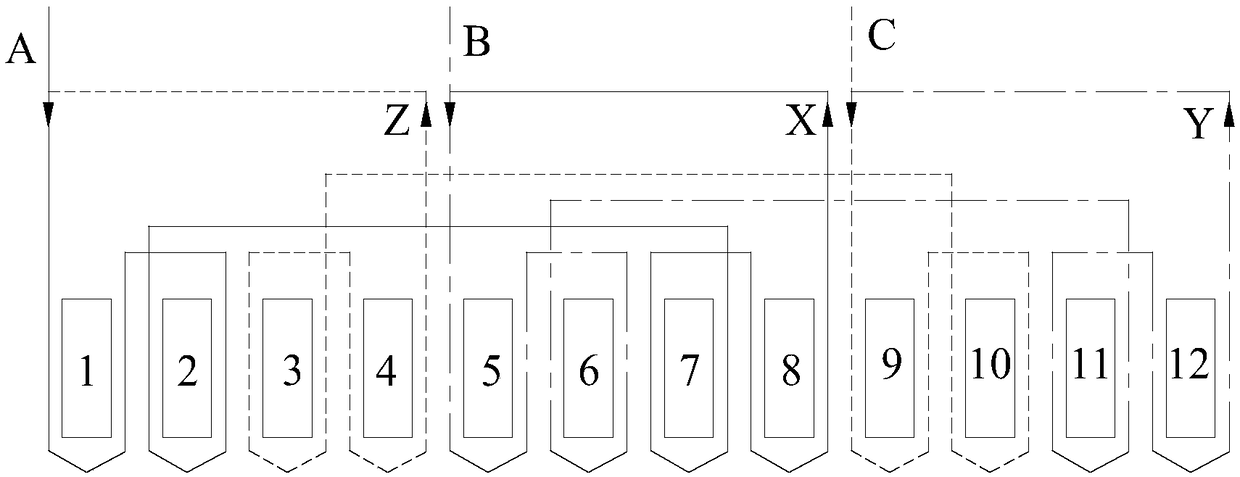

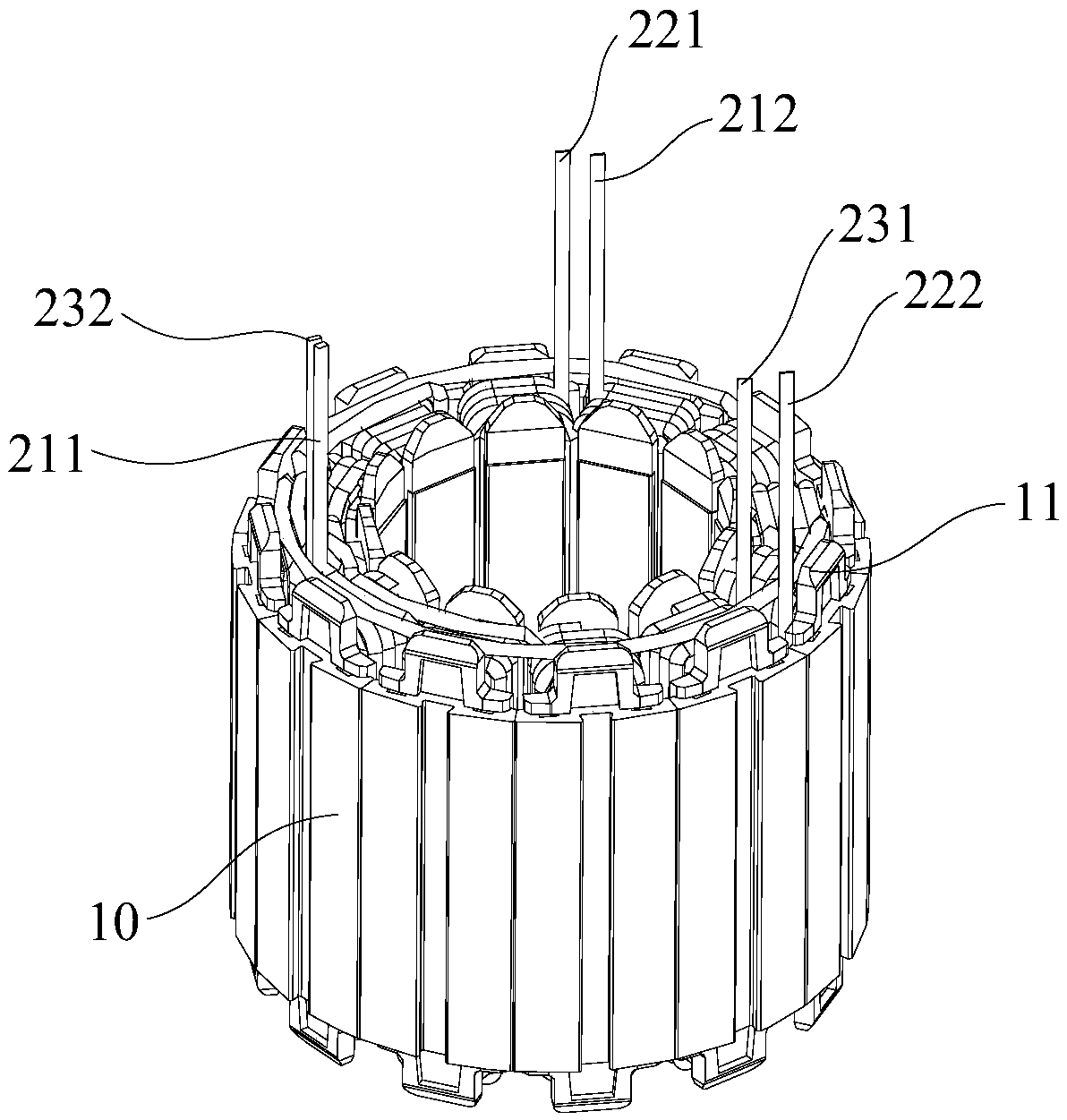

[0042] Such as Figure 3-11 As shown, the first embodiment of the present invention discloses a brushless motor stator. The brushless motor stator includes a stator core assembly 10 and a stator winding 20. The stator winding 20 is wound on the stator core assembly 10, and the stator core assembly 10 There are a plurality of winding teeth 11 spaced apart in the circumferential direction, a slot 12 is provided between any two adjacent winding teeth 11, and the stator winding 20 is accommodated in each slot 12 and wound from each slot 12 Set on each winding tooth 11, the stator winding 20 includes several phase windings, each phase winding includes two lead ends, and the adjacent lead ends of any two adjacent phase windings are located in the same slot 12. Adjacent lead ends of different phases pass through the same slot 12, simplifying the winding structure of the stator winding 20, making it simple in structure, good in manufacturability and high in efficiency.

[0043] Specifica...

Embodiment 2

[0052] Such as Figure 8-11 As shown, the second embodiment of the present invention also discloses another brushless motor stator with a winding structure. The difference from the first embodiment is: a first lead end 211, a second lead end 212, a third lead end 221, The fourth lead end 222, the fifth lead end 231, and the sixth lead end 232 are located on one side of the stator core assembly 10. The first bridge wire 213, the second bridge wire 223, and the third bridge wire 233 are located on the stator iron core. On the other side of the core assembly 10, the bridge wire of the three-phase winding is passed from the other side of the stator lead wire, which is in a different position from the incoming and outgoing wires, effectively avoiding the mutual influence between the two and avoiding the risk of manual threading. It is possible to increase / decrease half-turn coils, thereby increasing the flexibility of adjusting the number of coil turns.

[0053] The invention also di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com