Glass composition

A glass composition and composition technology, applied in the field of glass compositions, can solve the problems of low solar heat radiation transmittance, inability to provide blue-green, etc., achieve low solar heat radiation transmittance, prevent heating and ultraviolet transmission, high Effect of Visible Light Transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

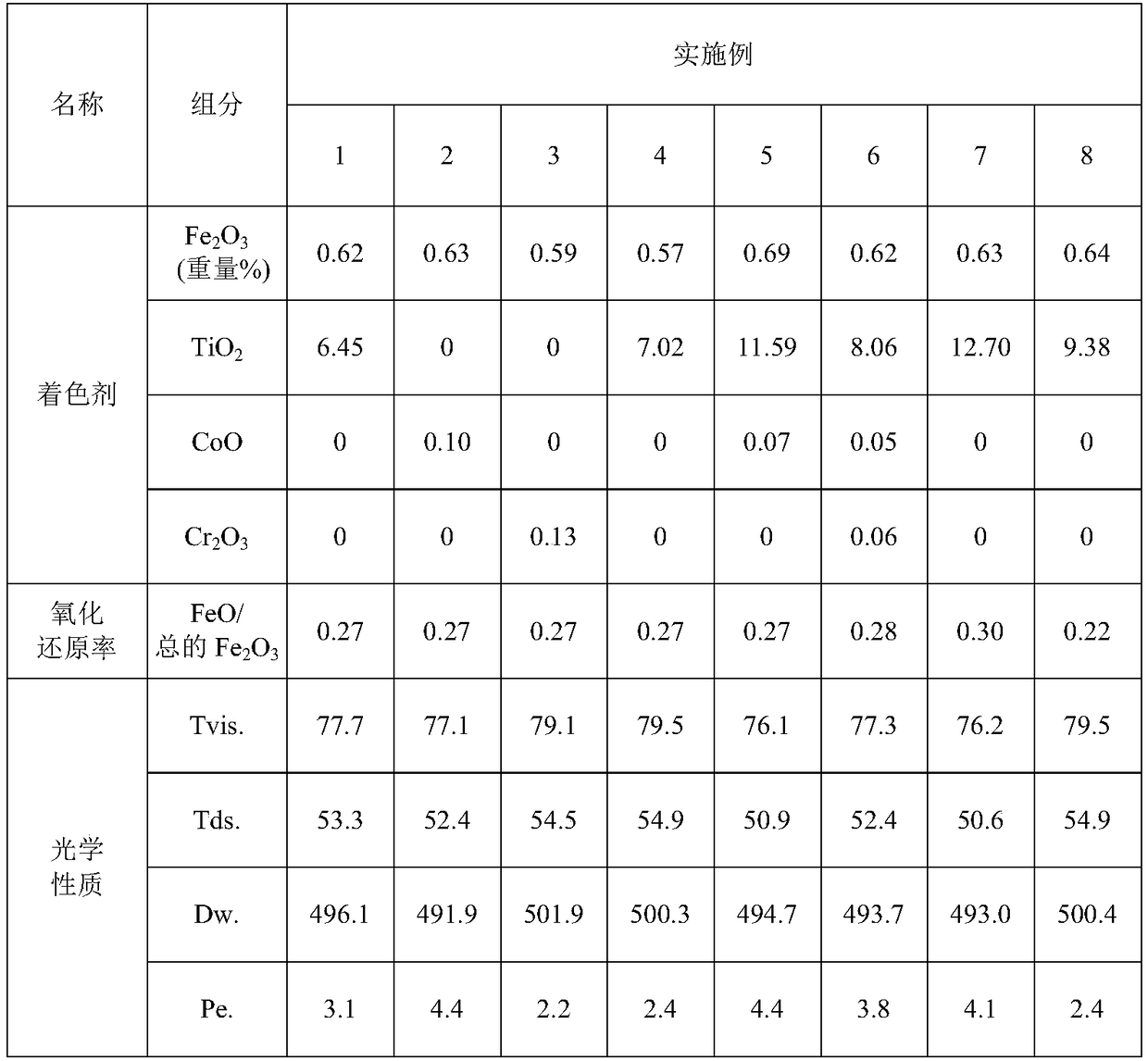

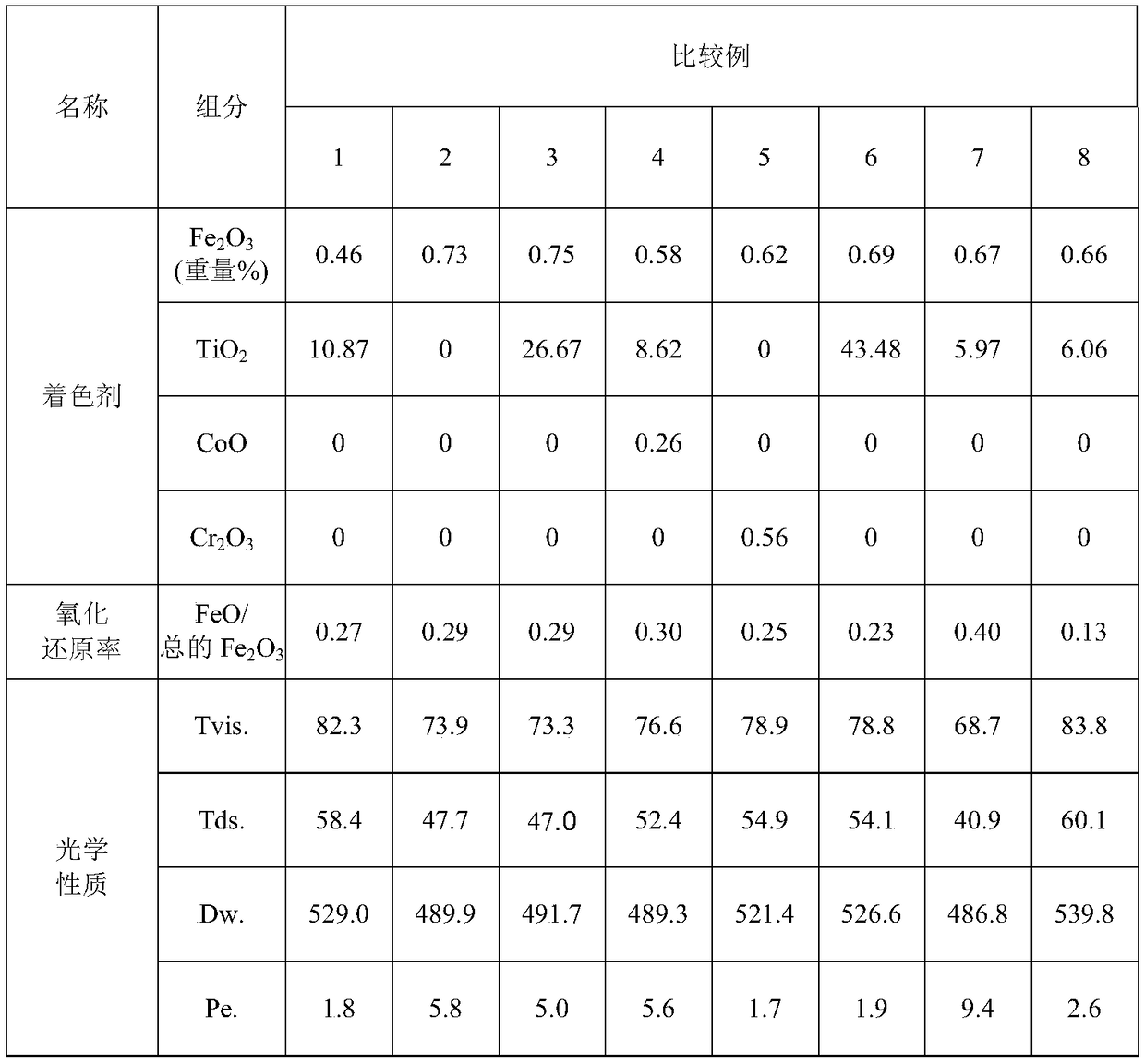

Examples

Embodiment

[0042] Glass melts described in all examples and comparative examples were prepared according to the following schemes.

[0043] In the manufacture of glass melts, the components are weighed and mixed in a mixer.

[0044] As raw materials, silica, feldspar, limestone, dolomite, soda ash, sodium sulfate, and iron oxide are used, and a glass batch is melted using a gas furnace or an electric furnace, wherein the mixing ratio of the glass batch is controlled to obtain the following implementation Examples and the target composition involved in the comparative example. The composition of the soda lime glass composition used is as follows, based on the weight % of the glass composition masterbatch excluding the colorant in the glass composition: 71.0% SiO 2 , 1.3% Al 2 o 3 , 9.8% CaO, 3.8% MgO, 13.9% Na 2 O, 0.15%dK 2 O and 0.2% SO 3 .

[0045] 500 g of the weighed mixture was put into a 90% platinum / 10% rhodium crucible and melted in a gas furnace at 1450° C. for 1 hour, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com