Modification preparation method of ultrafiltration membrane based on bionics and application of ultrafiltration membrane

A technology of ultrafiltration membrane and modifier, applied in the field of membrane separation, which can solve the problems of complex composition, difficult treatment and large emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

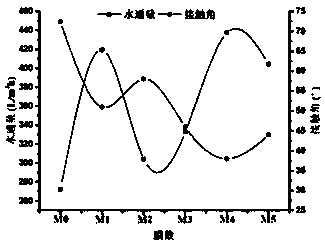

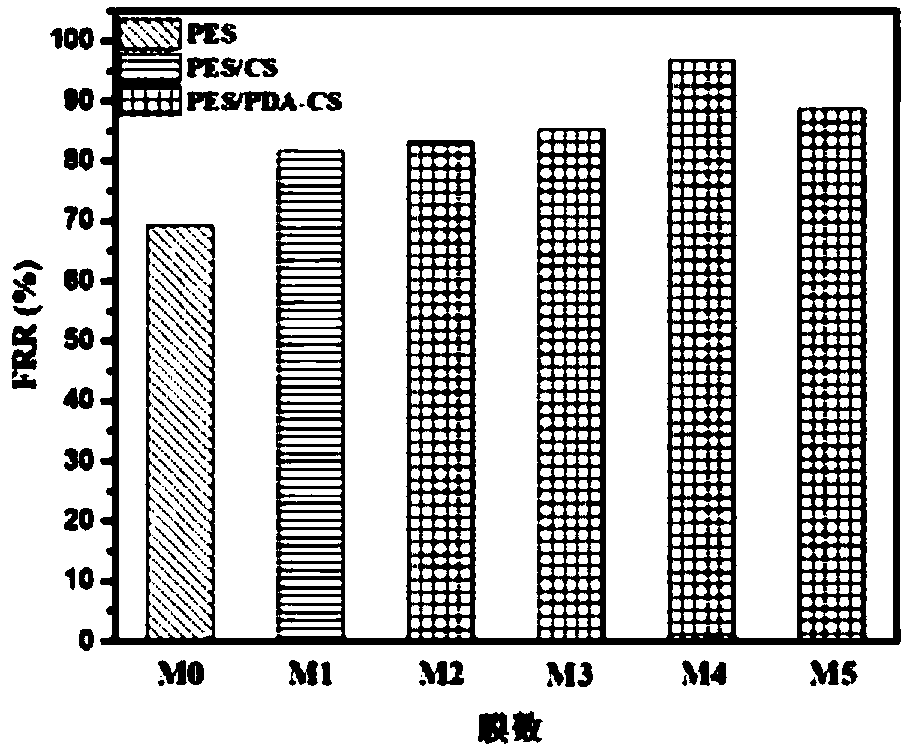

[0022] Weigh 0.1wt% of PDA-CS (the mass concentration of CS is 1.2%) and 75 g of N,N-dimethylacetamide are mixed in a conical flask and placed in an ultrasonic disperser for ultrasonic dispersion for 1 h. After dispersing evenly, add 18g of polyethersulfone and 7g of polyvinylpyrrolidone and mix evenly, then place in a water bath, heat at a constant temperature of 75°C and stir magnetically for 12 hours to fully dissolve it, and place it in a vacuum box at 60°C to stand Degassing for 4 hours to remove residual air bubbles in the solution to obtain the casting solution.

[0023] The preparation of the ultrafiltration membrane is carried out by using the method of flat-plate membrane production. First, pour the casting solution on a glass plate of 15 × 25 cm, and then use a glass rod to scrape the ultrafiltration membrane; put the glass plate containing the membrane coating at room temperature Pre-evaporate in air for 40s, and then immerse in a coagulation bath at 30°C, so that ...

Embodiment 2

[0040] Weigh 0.1wt% of PDA-CS (the mass concentration of CS is 1.6%) and 75 g of N,N-dimethylacetamide are mixed in a conical flask and placed in an ultrasonic disperser for ultrasonic dispersion for 1 h. After dispersing evenly, add 18g of polyethersulfone and 7g of polyvinylpyrrolidone and mix evenly, then place in a water bath, heat at a constant temperature of 75°C and stir magnetically for 12 hours to fully dissolve it, and place it in a vacuum box at 60°C to stand Degassing for 4 hours to remove residual air bubbles in the solution to obtain the casting solution.

[0041] The preparation of the ultrafiltration membrane is carried out by using the method of flat-plate membrane production. First, pour the casting solution on a glass plate of 15 × 25 cm, and then use a glass rod to scrape the ultrafiltration membrane; put the glass plate containing the membrane coating at room temperature Pre-evaporate in air for 40s, and then immerse in a coagulation bath at 30°C, so that ...

Embodiment 3

[0046] Weigh 0.1wt% PDA-CS (the mass concentration of CS is 2.0%) and 75 g N,N-dimethylacetamide, mix them in a conical flask and place them in an ultrasonic disperser for ultrasonic dispersion for 1 h. After dispersing evenly, add 18g of polyethersulfone and 7g of polyvinylpyrrolidone and mix evenly, then place in a water bath, heat at a constant temperature of 75°C and stir magnetically for 12 hours to fully dissolve it, and place it in a vacuum box at 60°C to stand Degassing for 4 hours to remove residual air bubbles in the solution to obtain the casting solution.

[0047] The preparation of the ultrafiltration membrane is carried out by using the method of flat-plate membrane production. First, pour the casting solution on a glass plate of 15 × 25 cm, and then use a glass rod to scrape the ultrafiltration membrane; put the glass plate containing the membrane coating at room temperature Pre-evaporate in air for 40s, and then immerse in a coagulation bath at 30°C, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com