Metal rigidity seal ball valve

A technology of hard sealing and ball valves, applied in valve details, valve devices, valve housing structures, etc., can solve problems such as high maintenance costs, reduced service life of valves, and damage to valve sealing, so as to reduce maintenance costs and prolong service life , Improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

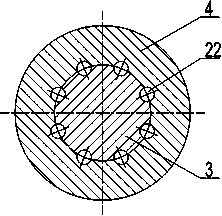

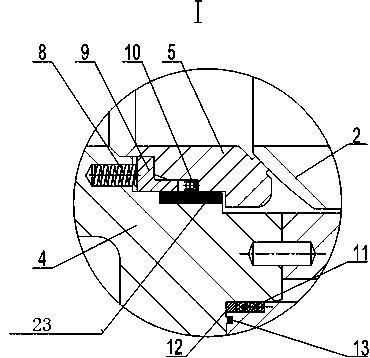

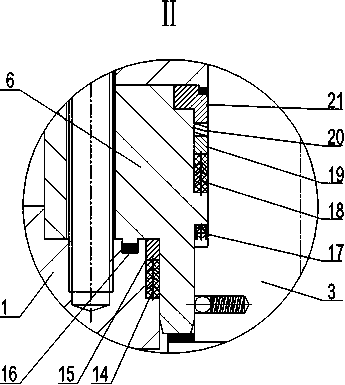

[0038] Figure 1 to Figure 4 In the embodiment, the valve body includes a middle valve body 1 located on the outer periphery of the ball, and a left valve cover and a right valve cover 2 respectively connected to both ends of the middle valve body 1; the left valve seat and the right valve seat 5 respectively pass the first sealing The assembly sealably connects the left and right bonnets. The middle valve body 1 and the left and right valve covers 2 are detachably connected by stud nuts, and the assembly is convenient and simple.

[0039] refer to image 3 As shown, the metal protection layer 23 on the outside of the first sealing ring is made of stainless steel, and is surfacing welded on the sealing surface of the left valve cover or the right valve cover 2 below the active area of the sealing ring. The stainless steel material has strong corrosion resistance, which can prevent the sealing area from damaging the first sealing ring due to corrosion, improves the sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com