An efficient heat dissipation transformer

A transformer and high-efficiency technology, applied in the field of transformers, can solve problems such as transformer burnout and unsatisfactory heat dissipation, and achieve the effects of improving efficiency, saving manufacturing materials and costs, and saving power resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

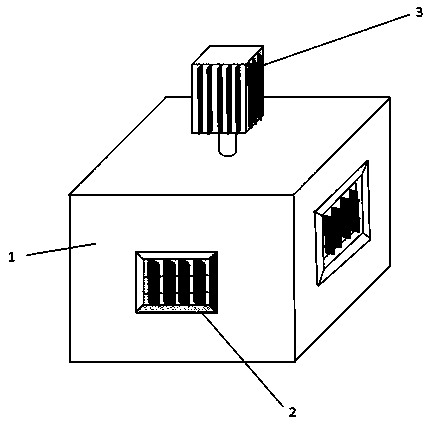

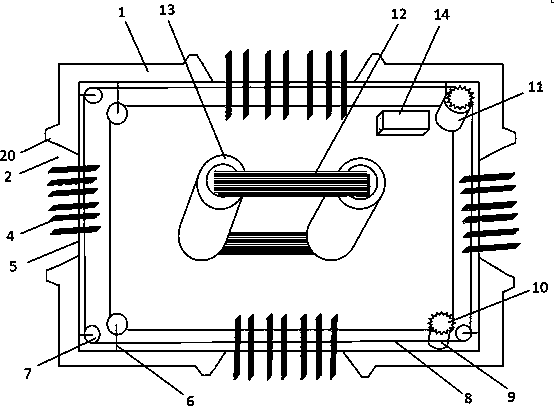

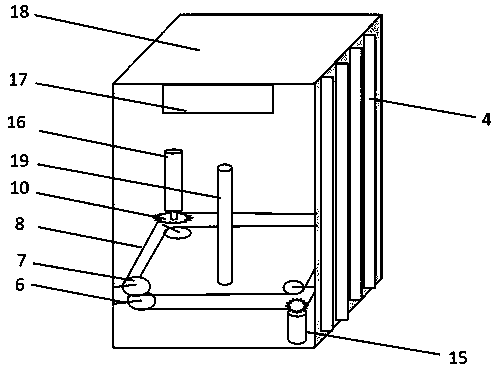

[0016] Embodiment 1: as Figure 1-3 As shown, a high-efficiency heat dissipation transformer includes a transformer box 1 and a window facing device 3 with the highest detection heat dissipation efficiency located above the transformer box 1; the transformer box 1 is a square body and is provided with windings 13, iron Core 12, fixed pulley 7, toothed belt 8, motor Ⅰ 9 and motor Ⅱ 11, control device 14; transformer box 1 is provided with a louver vent 2 on each of the four planes perpendicular to the ground, and the louver grille of the louver vent 2 4 is rotatably installed on the louver rotation shaft 5, and the rotation direction of the louver grille 4 in the left and right directions of the transformer box 1 is controlled by the movement of the upper toothed belt 8, and the upper toothed belt 8 is wound around the transformer box 1 at three right-angle positions and fixed The fixed pulley 7, the inner side of the louver rotating shaft 5 of the louver grid leaf 4 in the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com