Dual-station superhigh speed fully automatic aluminum electrolysis capacitor assembling method

An aluminum electrolytic capacitor and ultra-high-speed technology are applied in the direction of electrolytic capacitors, electrolytic capacitor manufacturing, and capacitors. The effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

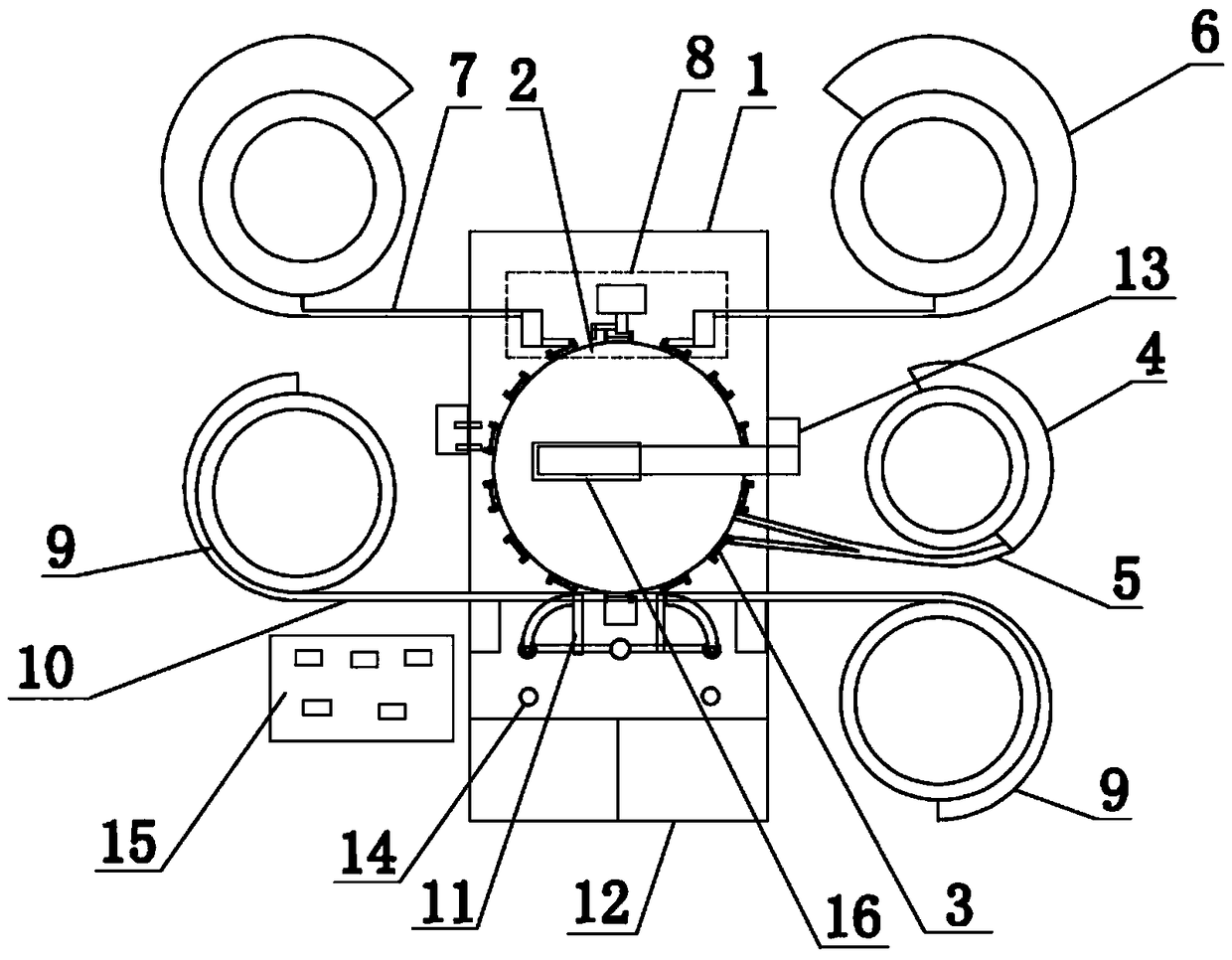

[0020] Such as figure 1 As shown, the dual-station ultra-high-speed automatic aluminum electrolytic capacitor assembly method includes a frame 1, a rubber particle clamping disc 2, a rubber particle clamping module 3, a rubber particle vibrating plate 4, and a rubber particle vibrating flat delivery mechanism 5, Suzi vibrating plate 6, Suzi vibrating flat feeding mechanism 7, Suzi feeding mechanism 8, aluminum shell vibrating plate 9, aluminum shell vibrating flat feeding mechanism 10, assembly sealing device 11, finished product receiving device 12, the middle part of the frame 1 A colloidal bead clamping disc 2 is provided, and several colloidal bead clamping modules 3 are provided on the outer wall of the colloidal bead clamping disc 2, and a colloidal bead vibrating plate 4 is provided on one side of the colloidal bead clamping disc 3, The front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com