Gate-turn-off thyristor and manufacturing method thereof

A thyristor and gate technology, applied in the field of gate turn-off thyristors, can solve the problem of large die area, and achieve the effects of low dynamic power consumption, reduced requirements and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The content of the present invention will be described below with specific examples.

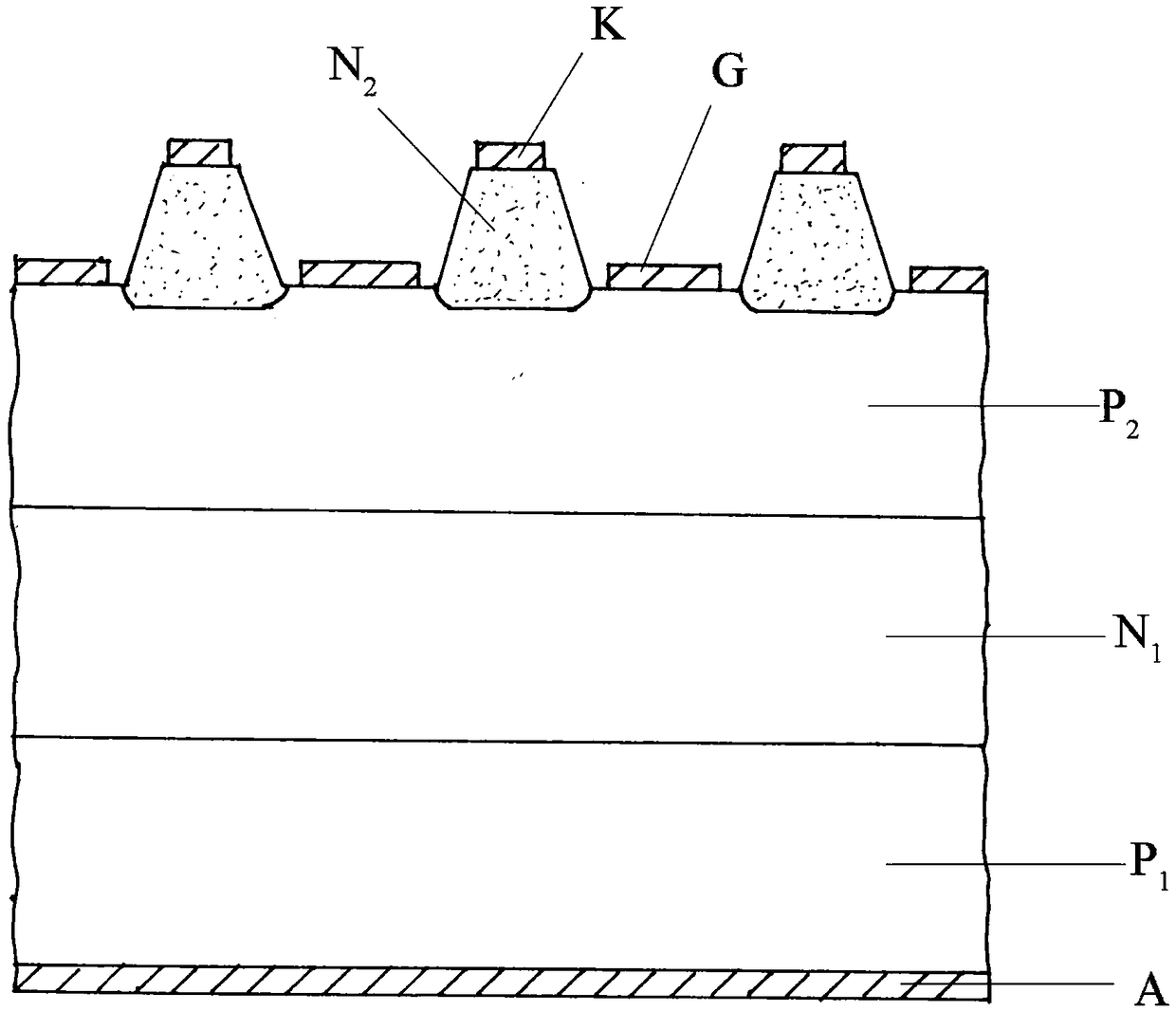

[0062] Firstly, the shape of the N-type emission area of the upper tube of the present invention can be rectangular, square, hexagonal, circular, trapezoidal, triangular or other shapes, and any combination of shapes, usually rectangular. For the sake of brevity, many descriptions in the manual use the rectangular shape of the N-type emission region of the upper tube, the rectangular shape of the P-type base region of the upper tube, and the rectangular shape of the P-type concentrated base region of the upper tube. This is an interdigitated structure of a common power transistor.

[0063] Secondly, the "connection" referred to in the present invention essentially refers to electrical connection, that is, electrical communication. The physical structure can be direct or indirect connection, which does not affect the electrical connection.

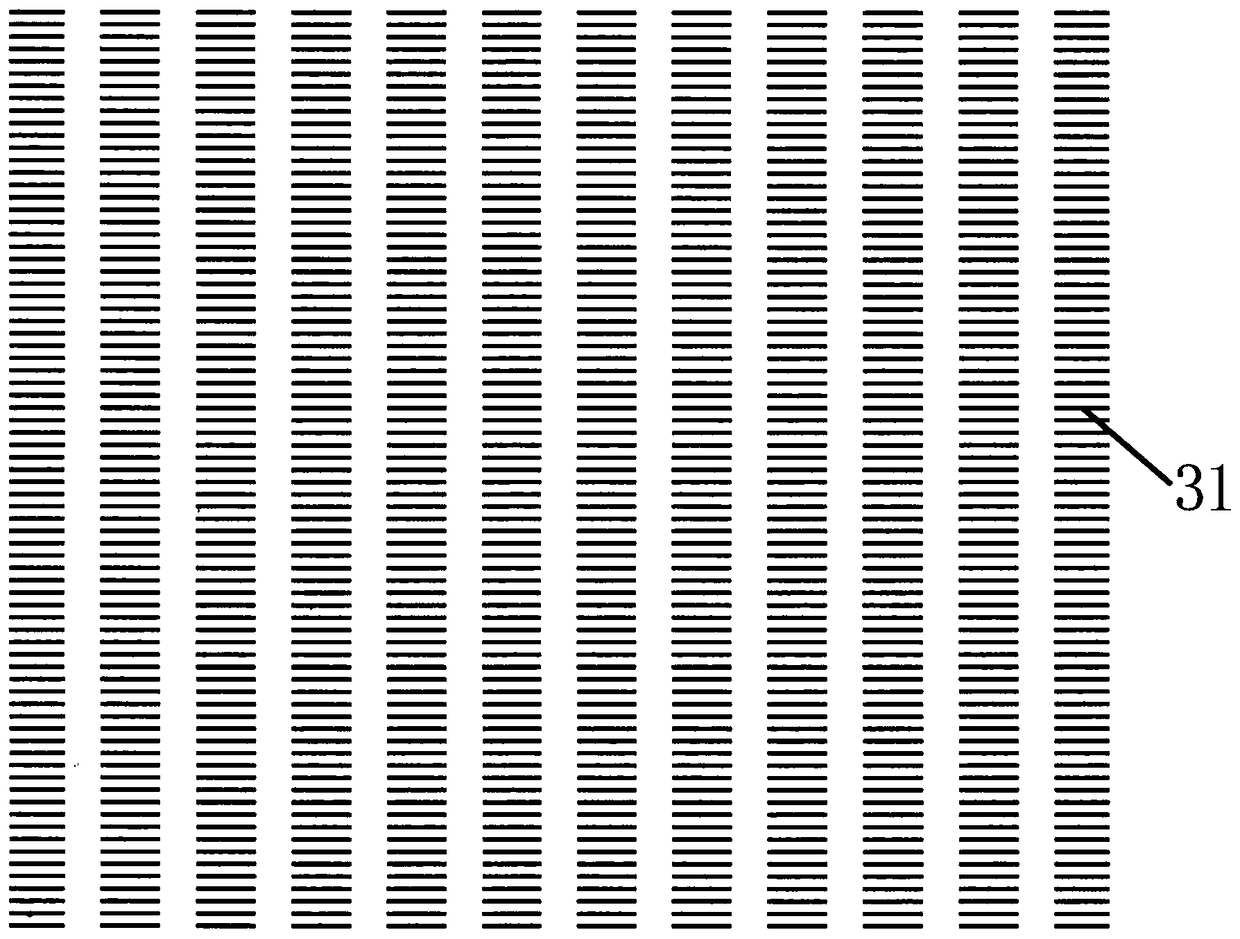

[0064] Thirdly, the "repeat distance" me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com