Storage battery charging control circuit in photovoltaic power generation system

A photovoltaic power generation system and charging control technology, applied in photovoltaic power generation, battery circuit devices, photovoltaic modules, etc., can solve the problems of inability to charge batteries, complex circuits, and high costs, reducing production and operation costs, simple circuit structure, and perfect charging. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the drawings.

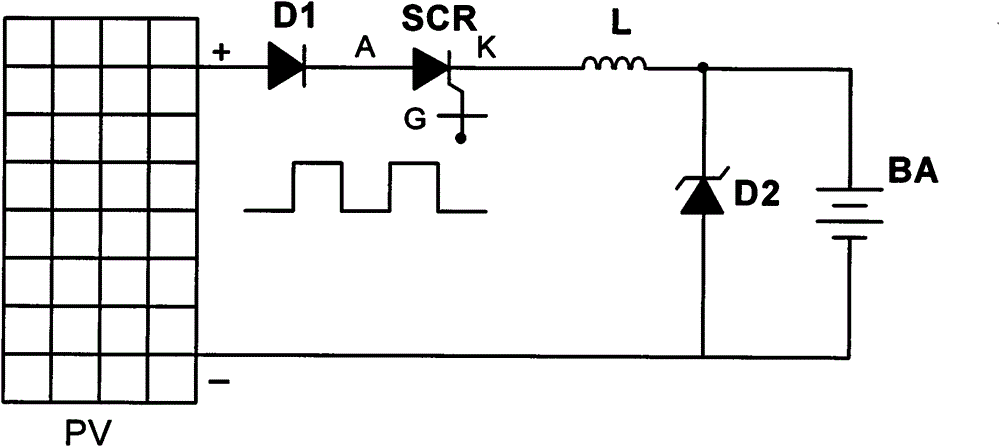

[0008] Such as figure 1 As shown, the anode of the solar cell panel PV is connected to the anode of the first diode D1, and the cathode of the first diode D1 is connected to the anode A terminal of the turn-off thyristor SCR, and the cathode K of the thyristor SCR can be turned off. The cathode of the piezoelectric diode D2 is connected to one end of the inductor L, and the other end of the inductor L is connected to the anode of the battery BA. After the cathode of the battery BA is connected to the anode of the Zener diode D2, it is then connected to the cathode of the solar panel PV. When a positive and negative trigger signal is applied to the G terminal of the switchable thyristor, the switchable thyristor can be turned off by itself, which realizes the regulation of the charging voltage of the battery BA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com