Baiwei chicken and production process thereof

A production process and technology of Baiwei chicken, which is applied in the field of food processing, can solve the problems of poor chicken taste, damage to the meat structure, loss of aroma, etc., and achieve the effect of inhibiting the growth and reproduction of bacteria, good taste and overflowing aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1: a kind of hundred flavor chicken, raw material and corresponding parts by weight thereof are as shown in table 1, and its production process comprises the following steps:

[0056] Step 1: Add water, sugar, salt, monosodium glutamate, and spices into the pot, stir and mix evenly, then add chilled chicken, and the chilled chicken is submerged under the liquid surface;

[0057] Step 2, heat the liquid in the pot to 90°C and cook for 0.5 hours, then cool down to 85°C and cook for 3 hours;

[0058] Step 3, frying the cooked chilled chicken at a constant temperature until golden yellow, so that the color of the skin is bright, the frying temperature is 170° C., and the frying time is 2 minutes to obtain cooked chicken;

[0059] Step 4: Rapidly cool the fried cooked chicken in a rapid cooling tunnel at -10±2°C, control the product discharge temperature at 10°C, and cool down for 30 minutes;

[0060] Step 5, the cooled cooked chicken is taken out and sealed and ...

Embodiment 2-5

[0070] Embodiment 2-5: a kind of chicken with a variety of flavors. The difference from Embodiment 1 is that the raw materials and their corresponding parts by weight are shown in Table 1.

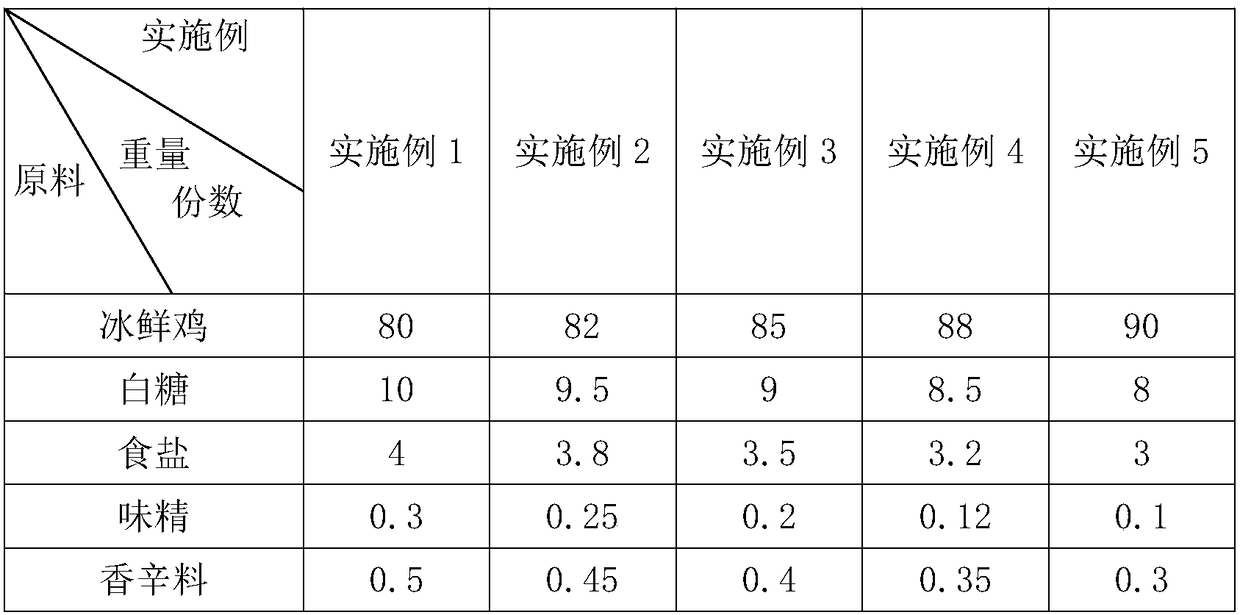

[0071] Raw materials and parts by weight thereof in table 1 embodiment 1-5

[0072]

Embodiment 6

[0073] Embodiment 6: a kind of chicken with a variety of flavors, the difference from embodiment 1 is that the spices include the following raw materials in parts by weight:

[0074] 9 parts fragrant leaves;

[0075] 8 parts cumin;

[0076] 10 parts cinnamon;

[0077] 5 parts star anise;

[0078] 4 parts nutmeg;

[0079] 8 cloves;

[0080] 6.5 servings of Cao Guo;

[0081] Kaempfer 3 servings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com