Corrosion-resistant copper wire for oil filter net and manufacturing technology thereof

An oil filter and corrosion-resistant technology, which is applied in the field of copper wire, can solve the problems of copper wire punching, corrosive liquid corrosion, and low service life of the oil filter, achieving increased hardness, long service life, and increased life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

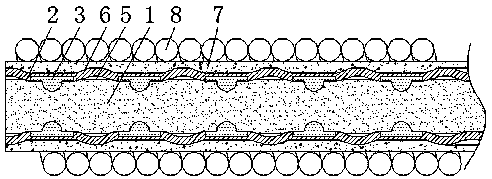

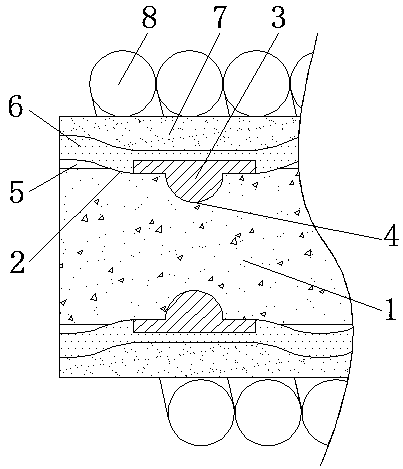

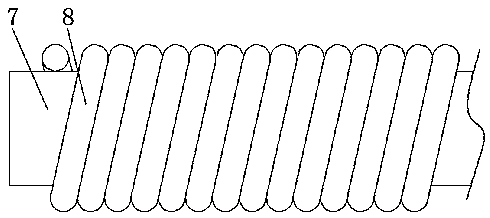

[0037]A corrosion-resistant copper wire for an oil filter, comprising a copper wire body 1, the surface of the copper wire body 1 is provided with arc-shaped grooves 2, and the arc-shaped grooves 2 are provided on the side surface of the copper wire body 1, and each arc-shaped groove 2 Around the copper wire body 1, the inner wall of the arc-shaped groove 2 is fixedly connected with a galvanized layer 3, which can prevent electrochemical corrosion to a certain extent. The inner wall of the arc-shaped groove 2 is provided with an annular groove 4, and the galvanized layer 3 is fixedly connected. On the inner wall of the annular groove 4, the annular groove 4 corresponds to the galvanized layer 3, the center of the annular groove 4 coincides with the center of the copper wire body 1, the annular groove 4 circles the copper wire body 1, and the surface of the copper wire body 1 Fixedly connected with the inner wall of the reinforcement layer 5, the reinforcement layer 5 is a brass...

Embodiment 2

[0046] A corrosion-resistant copper wire for an oil filter, comprising a copper wire body 1, the surface of the copper wire body 1 is provided with arc-shaped grooves 2, and the arc-shaped grooves 2 are provided on the side surface of the copper wire body 1, and each arc-shaped groove 2 Around the copper wire body 1, the inner wall of the arc-shaped groove 2 is fixedly connected with a galvanized layer 3, which can prevent electrochemical corrosion to a certain extent. The inner wall of the arc-shaped groove 2 is provided with an annular groove 4, and the galvanized layer 3 is fixedly connected. On the inner wall of the annular groove 4, the annular groove 4 corresponds to the galvanized layer 3, the center of the annular groove 4 coincides with the center of the copper wire body 1, the annular groove 4 circles the copper wire body 1, and the surface of the copper wire body 1 Fixedly connected with the inner wall of the reinforcement layer 5, the reinforcement layer 5 is a bras...

Embodiment 3

[0055] A corrosion-resistant copper wire for an oil filter, comprising a copper wire body 1, the surface of the copper wire body 1 is provided with arc-shaped grooves 2, and the arc-shaped grooves 2 are provided on the side surface of the copper wire body 1, and each arc-shaped groove 2 Around the copper wire body 1, the inner wall of the arc-shaped groove 2 is fixedly connected with a galvanized layer 3, which can prevent electrochemical corrosion to a certain extent. The inner wall of the arc-shaped groove 2 is provided with an annular groove 4, and the galvanized layer 3 is fixedly connected. On the inner wall of the annular groove 4, the annular groove 4 corresponds to the galvanized layer 3, the center of the annular groove 4 coincides with the center of the copper wire body 1, the annular groove 4 circles the copper wire body 1, and the surface of the copper wire body 1 Fixedly connected with the inner wall of the reinforcement layer 5, the reinforcement layer 5 is a bras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com