Purification apparatus and purification method combining spraying and photocatalytic degradation

A purification device and photocatalytic technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of poor degradation effect and high cost, and achieve the effect of improving degradation rate and degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

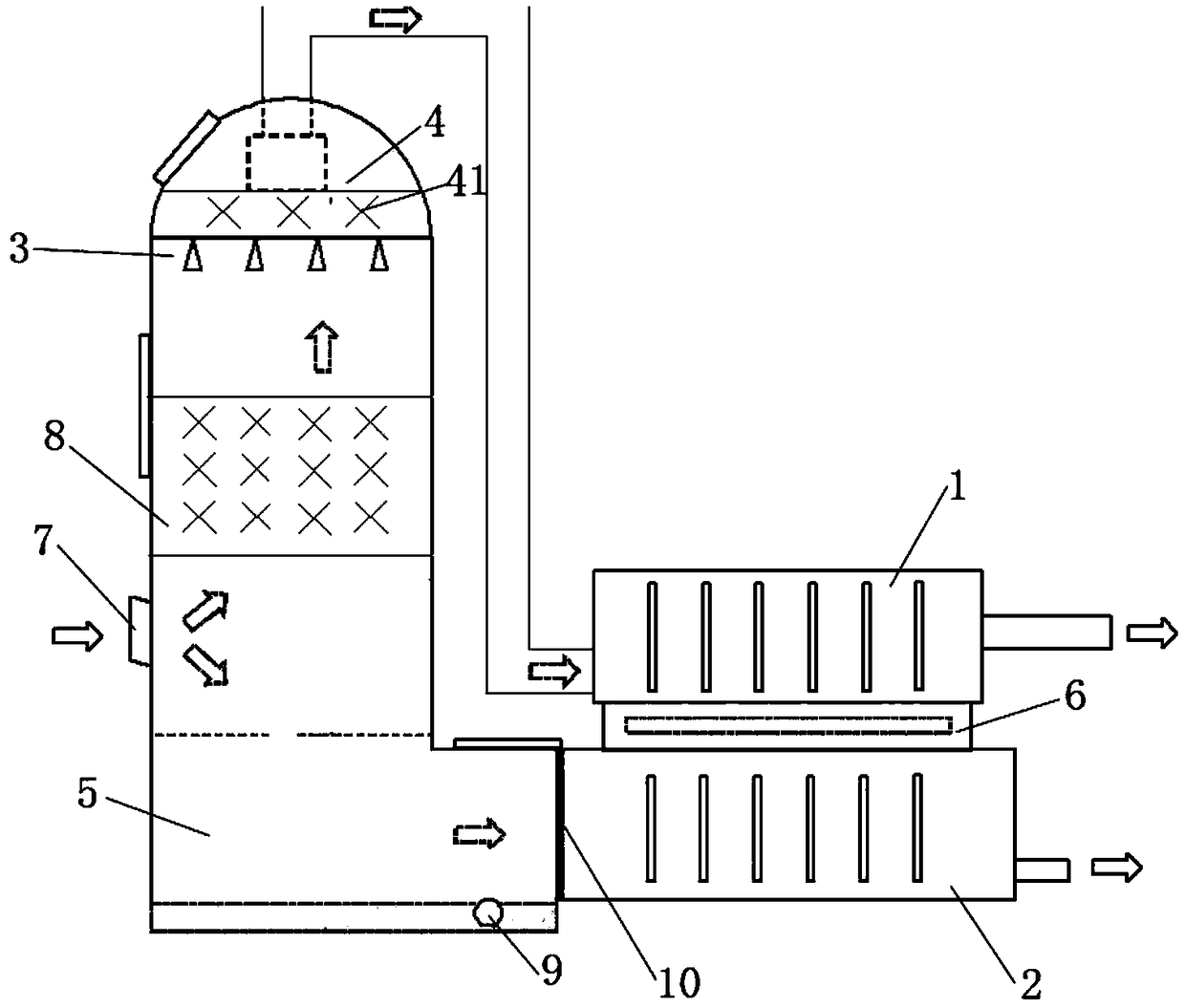

[0030] In practice, the spray system may include a communicable vessel, such as a spray tower. The spray tower is provided with a spray area 3 and a dehumidification area 4 for controlling the humidity of hydrophobic pollutants in the polluted gas, and the dehumidification area 4 is arranged above the spray area 3 . The spray area 3 is an area for spraying gas, in which a plurality of spray heads and other devices for spraying liquid can be arranged. The nozzle can be PP spiral nozzle, solid cone nozzle. In the dehumidification zone 4, defogging fillers 41 and the like can be installed. The defogging fillers 41 mainly collect water mist through contact with the fillers to condense on the filler surface to change the humidity. Changing the filler filling area can change the gas flow rate in a small range and increase the demist The mist filler can increase the contact area to facilitate dehumidification. The gas flow rate is mainly controlled by the fan (not shown in the sche...

Embodiment 2

[0044] As mentioned above, the purification method of polluting gas, after spraying the polluting gas with a spray system, dissolves the hydrophilic pollutants in the liquid phase and the hydrophobic pollutants that are still in the gaseous state, and converts the solution into a liquid phase The hydrophilic pollutants are passed into the liquid phase degradation unit 2 for photocatalytic degradation, and the hydrophobic pollutants which are still gaseous are passed into the gas phase degradation unit 1 for photocatalytic degradation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com